Preparation method of graphene surface cobalt plating reinforced cobalt-based alloy composite powder for selective laser melting forming

A technology of selective laser melting and graphene surface, applied in the direction of additive processing, etc., can solve the problems of poor wettability between graphene and substrate, large specific surface area, and loose bonding, achieving good sphericity, excellent performance, and avoiding oxidation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

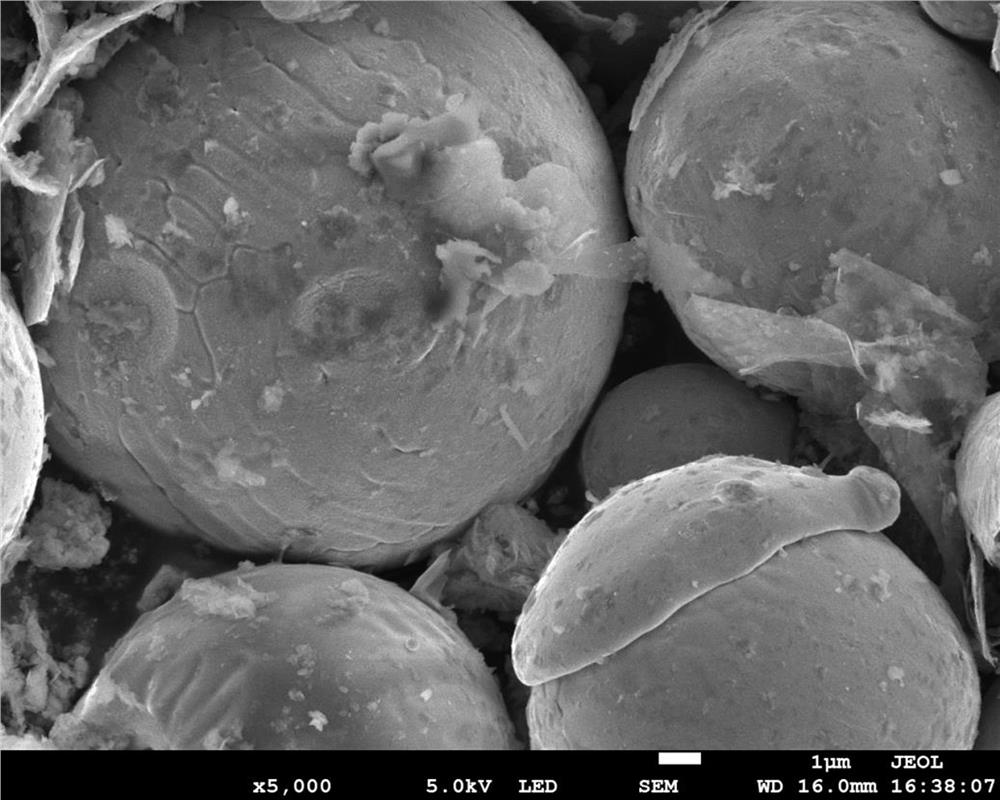

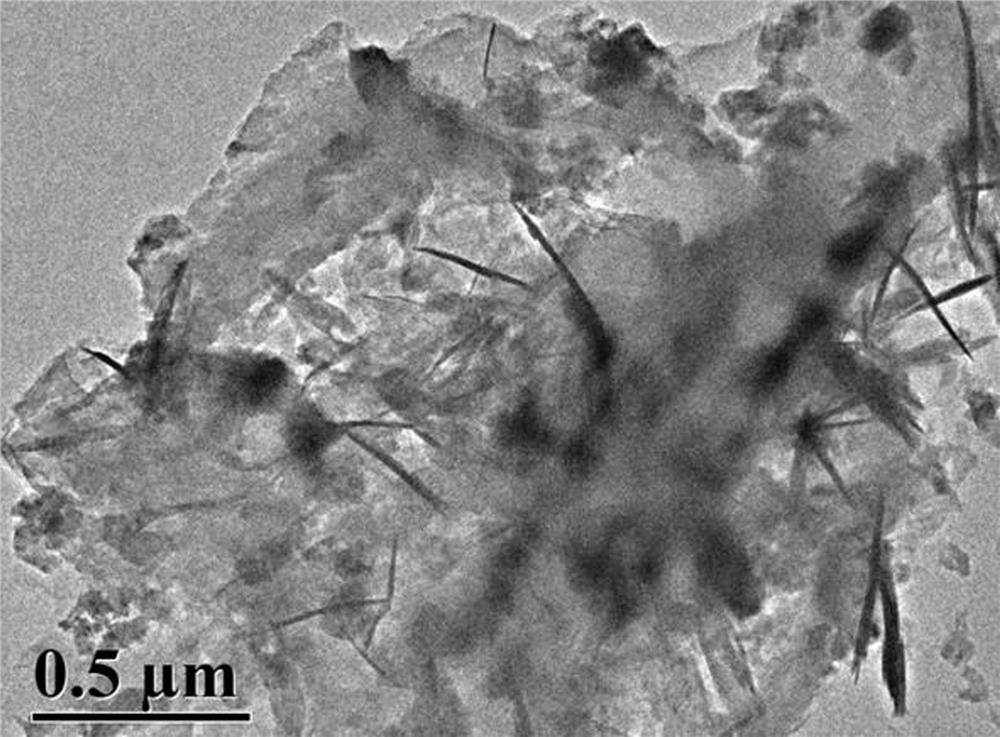

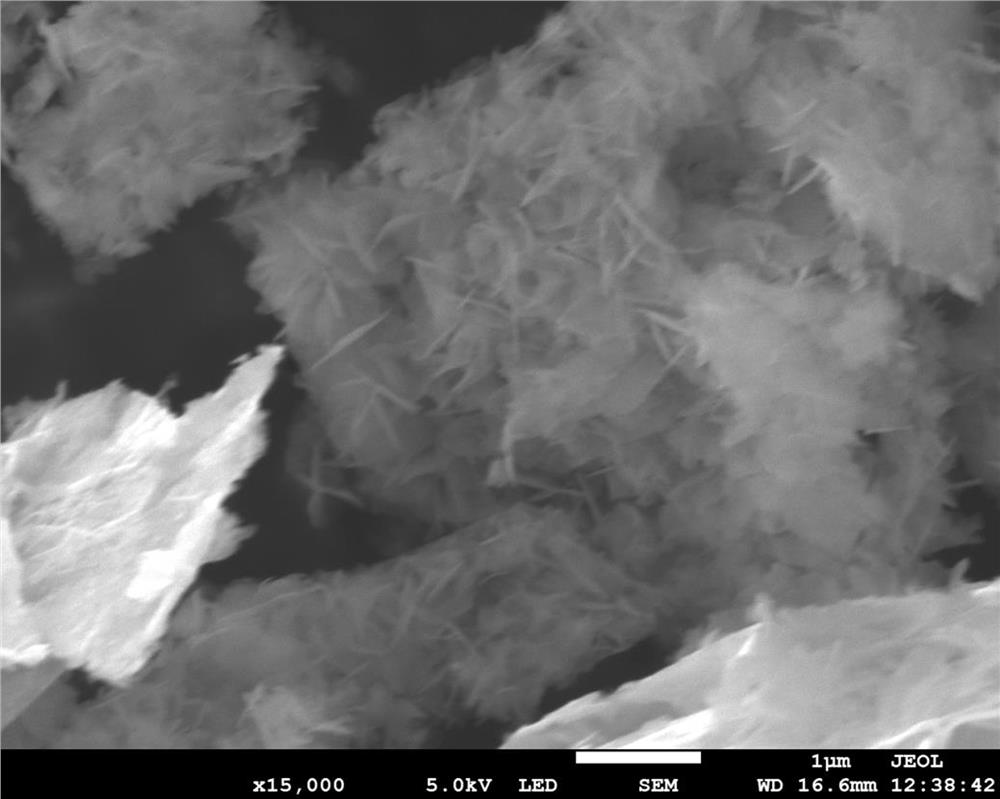

Image

Examples

Embodiment 1

[0030] This embodiment provides hydrothermal synthesis of cobalt-plated graphene process:

[0031] (1) Weigh 0.1 g of graphene dissolve in 40 ml of ethylene glycol ((CH) 2 OH) 2 In solution, ultrasonic dispersion; then, 0.5 g of hexahydrate chloride (COCL) 2 · 6h 2 O) Add the above mixed solution, stir well, add 10 drops of ammonia (NH 3 · H 2 O) Adjust the pH of the solution to 9-10 to obtain a graphene solution;

[0032] (2) Take 1 mL of hydration (N 2 Hide 4 · H 2 O), add 9 ml of deionized water, obtain a hydration of a hydration of a volume fraction of 10%;

[0033] (3) Heat the graphene solution, when the temperature rises to 85 ° C, slowly add the diluted reducing agent water in a diluted reducing agent water in 2 to 3 drops per second. 2 Hide 4 · H 2 O Solution (the volume fraction of 10% hydration solution);

[0034] The reducing property of hydration is reduced in graphene surface and the interlayer reduction of cobalt metal particles, and the reaction equation involved i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com