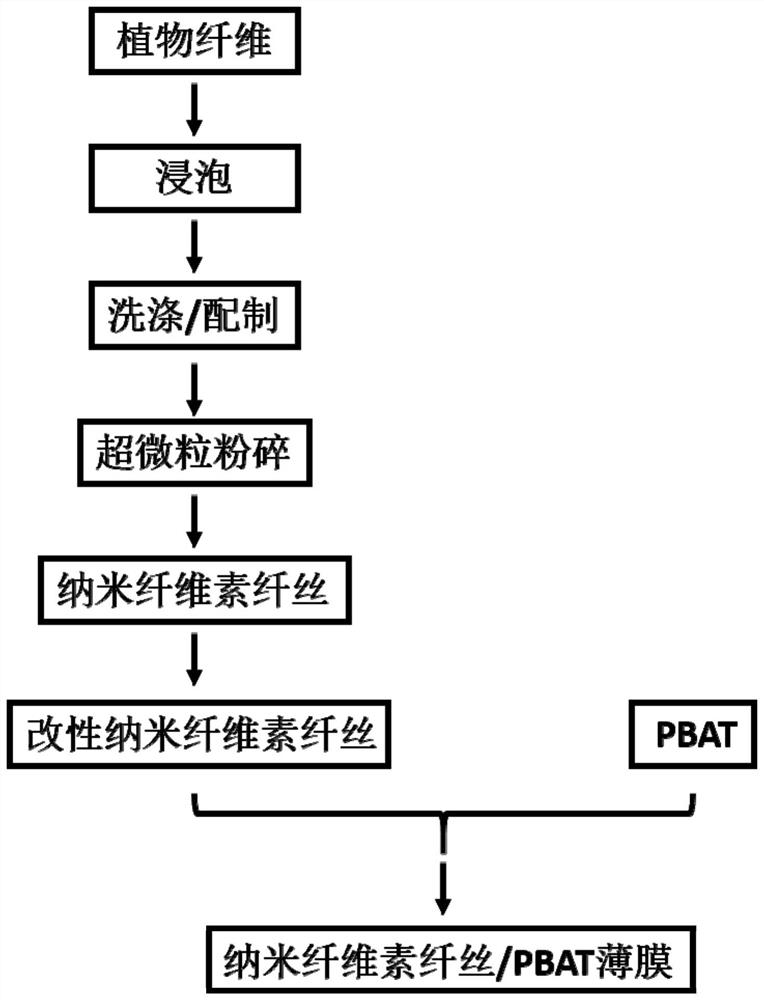

Nano-cellulose fibril /PBAT film and preparation method and application thereof

A technology of nanocellulose and plant cellulose, which is applied in the direction of fiber processing, fiber raw materials, plant fibers, etc., to achieve the effect of expanding the scope of application, good water resistance, and expanding the application system

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] A kind of nano cellulose fibril / PBAT film, its preparation method is as follows:

[0039] (1) Soak 50g of softwood pulp in a mixed solution (0.5mol / L buffer) of citric acid and sodium hydroxide molar ratio of 0.3:1 for 12h, then take it out and wash it with distilled water until it is neutral, then wash it with distilled water Prepared as a 2% pulp suspension.

[0040] (2) getting the mass fraction that obtains in step (1) is 2.5L of pulp suspension liquid of 2%, carries out pulverizing process with superfine particle pulverizer (Japan Zengxing Industrial Co., Ltd., model: MKCA6-2J), and the rotating speed is 2000r / min, the gap is -10 μm, and the cyclic crushing treatment is performed 10 times to obtain nanocellulose fibrils in an aqueous dispersion system.

[0041] (3) Get the nanocellulose fibrils of the water dispersion system prepared in step (2) and use tetrahydrofuran to carry out centrifugal washing, then be mixed with the nanocellulose fibril tetrahydrofuran s...

Embodiment 2

[0044] A kind of nano cellulose fibril / PBAT film, its preparation method is as follows:

[0045] (1) Soak 50g of softwood pulp in a mixed solution (0.5mol / L buffer solution) with a molar ratio of citric acid and sodium hydroxide of 1:1 for 36h, then take it out and wash it with distilled water until it is neutral, then wash it with distilled water Prepared as a 2% pulp suspension.

[0046](2) getting the mass fraction obtained in step (1) is 2.5L of pulp suspension of 2%, carry out pulverization process with ultrafine particle pulverizer, rotating speed is 5000r / min, gap is-20μm, circulation pulverization process 20 times, obtain Nanocellulose fibrils in aqueous dispersions.

[0047] (3) get the nanocellulose fibrils of the water dispersion system prepared in step (2) and use dichloromethane to carry out centrifugal washing, then be mixed with the nanocellulose fibrils dichloromethane solution that the mass fraction is 5%, get 100g, Use 2g of acetic anhydride at 25°C for 24 ...

Embodiment 3

[0050] A kind of nano cellulose fibril / PBAT film, its preparation method is as follows:

[0051] (1) Soak 200g of softwood pulp in a mixed solution of citric acid and sodium hydroxide with a molar ratio of 1:1 (0.5mol / L buffer solution) for 48h, then take it out and wash it with distilled water until it is neutral, and then wash it with distilled water Prepared as a 5% pulp suspension.

[0052] (2) Get the mass fraction that obtains in the step (1) and be 5% pulp suspension 2.5L, carry out pulverization process with ultrafine particle pulverizer, rotating speed is 1000r / min, and gap is-10 μm, circulation pulverization process 10 times, obtain Nanocellulose fibrils in aqueous dispersions.

[0053] (3) Get the nanocellulose fibrils of the water dispersion system prepared in step (2) and use acetone to carry out centrifugal washing, then be mixed with the nanocellulose fibril acetone solution that the mass fraction is 5%, get 20g, use 1g isosulfur The cyanate compound is modifi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com