Surface-modified and fiber-reinforced polyurethane composite material and preparation method thereof

A technology of surface modification and fiber reinforcement, which is applied in the field of polyurethane materials, can solve the problems of not fully meeting the requirements of use, affecting the effect of fiber reinforcement, and easy agglomeration of fibers, etc., to achieve improved interface bonding, good performance, and high mechanical strength. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] The surface-modified fiber-reinforced polyurethane composite material of this embodiment includes the following components in parts by weight: 100 parts of composite polyether polyol, 1.0 parts of silicone oil, 1.2 parts of catalyst, 1 part of coupling agent, 8 parts of composite foaming agent, 5 parts of fuel, 30 parts of isocyanate and 18 parts of surface modified palm fiber.

[0031] Wherein, the preparation method of the surface-modified palm fiber is as follows: after alkali treatment of the palm fiber with lye for 1 hour, heat treatment at 80° C. for 30 minutes; In the aluminate coupling agent, after reacting for 1 h, dry to obtain the surface-modified palm fiber; the components of the lye are shown in Tables 1-2 respectively.

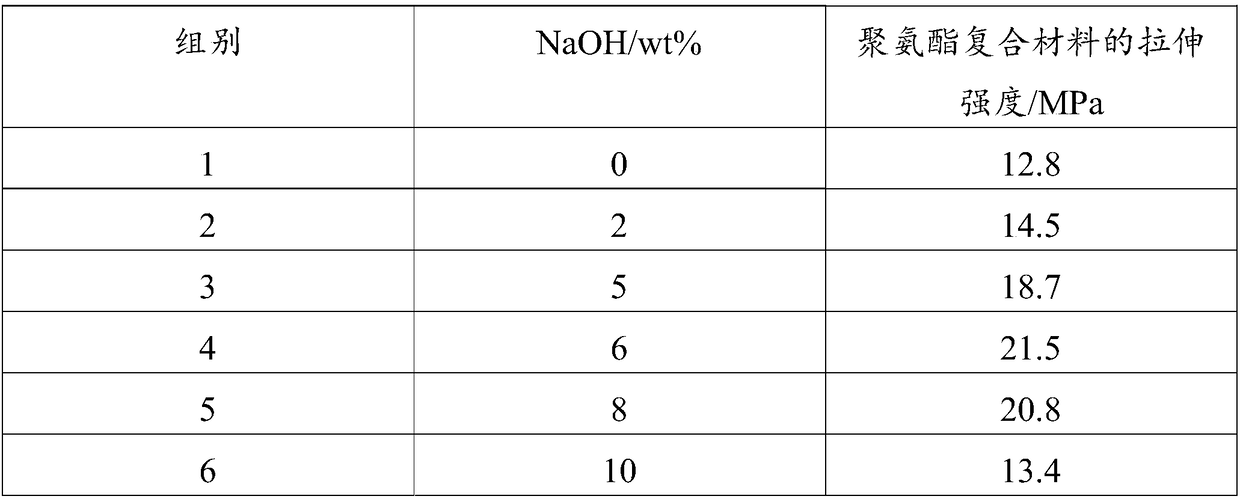

[0032] Table 1

[0033]

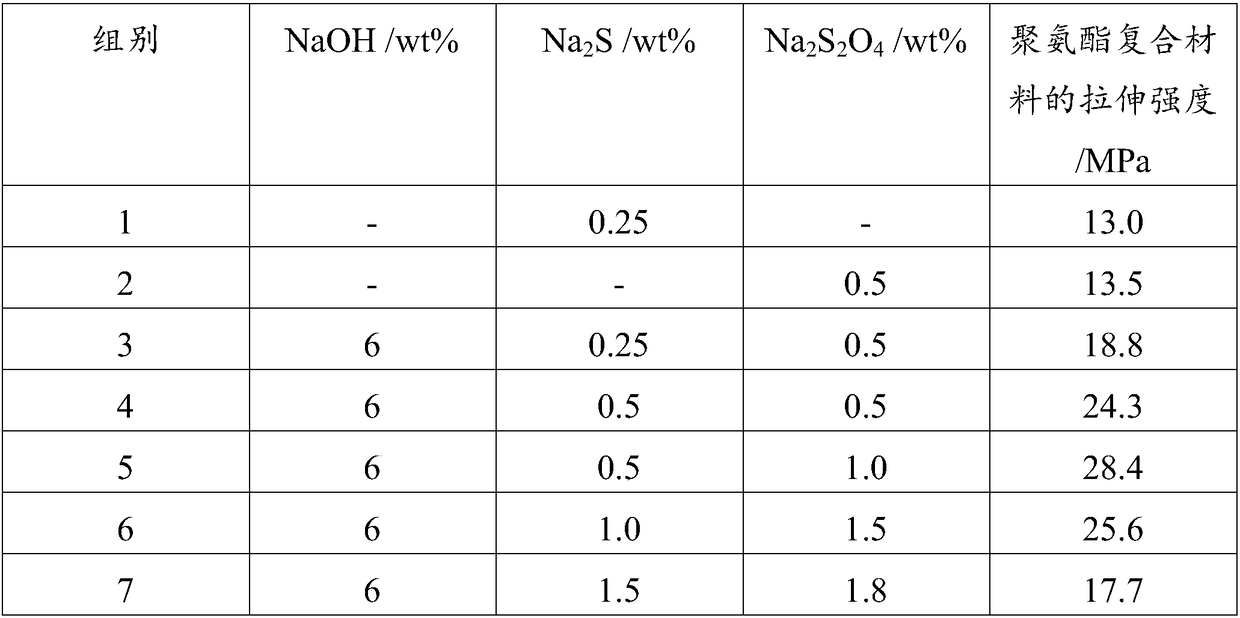

[0034] Table 2

[0035]

[0036] The composite polyether polyol comprises polyether polyol 1 and polyether polyol 2, the hydroxyl value of polyether polyol 1 is 150mgKOH / g, the hydroxyl value of polyether ...

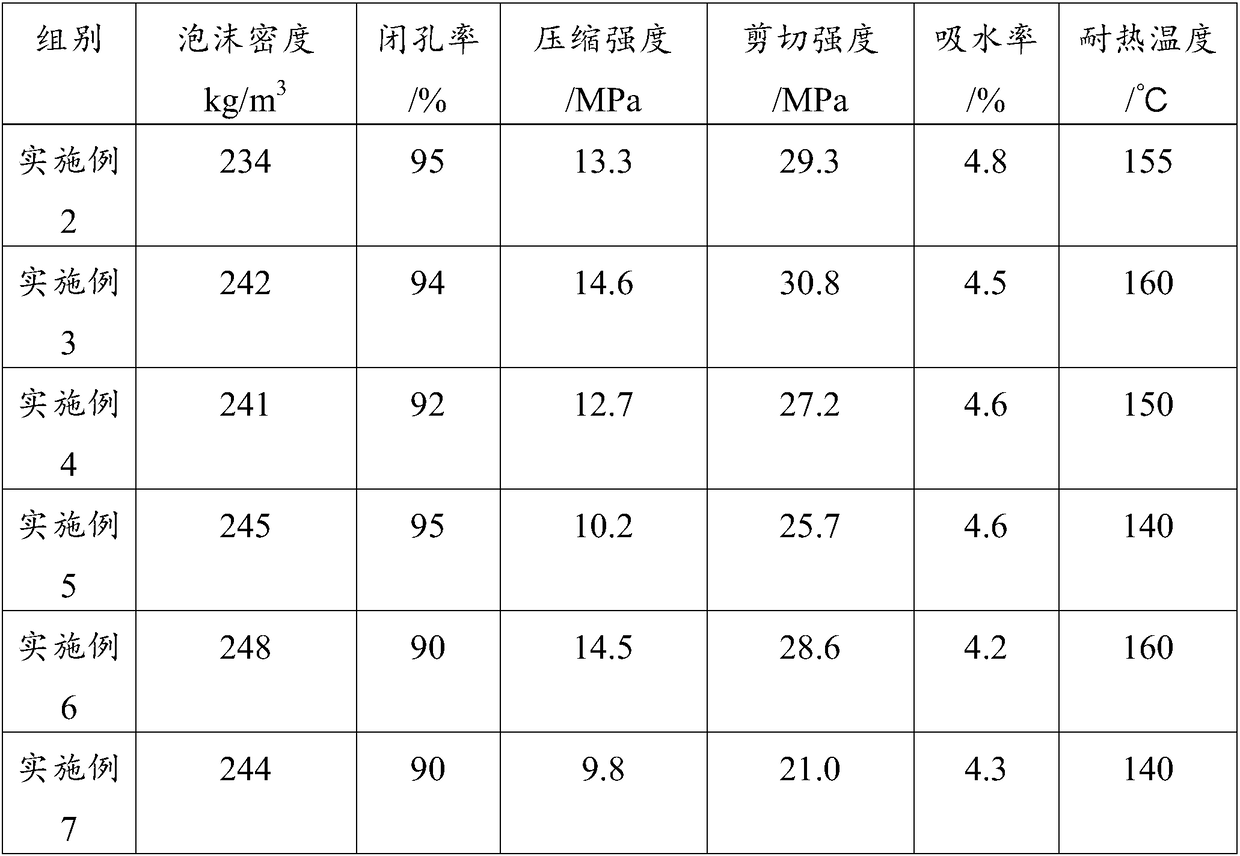

Embodiment 2

[0046] The surface-modified fiber-reinforced polyurethane composite material of this embodiment includes the following components in parts by weight: 100 parts of composite polyether polyol, 0.8 parts of silicone oil, 1.2 parts of catalyst, 2.4 parts of coupling agent, 10 parts of composite foaming agent, 5 parts of fuel, 30 parts of isocyanate and 16 parts of surface modified palm fiber.

[0047] Wherein, the preparation method of the surface-modified palm fiber is as follows: after alkali treatment of the palm fiber with lye, heat treatment at 80° C. for 25 minutes; In the aluminate coupling agent, after reacting for 1h, dry to obtain the surface modified palm fiber; the concentration of NaOH in the lye is 6wt%, and NaOH 2 The concentration of S is 0.5wt%, Na 2 S 2 o 4 The concentration is 1.0wt%.

[0048] The composite polyether polyol comprises polyether polyol 1 and polyether polyol 2, the hydroxyl value of polyether polyol 1 is 200mgKOH / g, the hydroxyl value of polye...

Embodiment 3

[0056] The surface-modified fiber-reinforced polyurethane composite material of this embodiment includes the following components in parts by weight: 100 parts of composite polyether polyol, 1.4 parts of silicone oil, 0.9 parts of catalyst, 1.8 parts of coupling agent, 12 parts of composite foaming agent, 6 parts of fuel, 28 parts of isocyanate and 20 parts of surface modified palm fiber.

[0057] Wherein, the preparation method of the surface-modified palm fiber is as follows: after alkali treatment of the palm fiber with lye, heat treatment at 80° C. for 25 minutes; In the aluminate coupling agent, after reacting for 1h, dry to obtain the surface modified palm fiber; the concentration of NaOH in the lye is 6wt%, and NaOH 2 The concentration of S is 0.5wt%, Na 2 S 2 o 4 The concentration is 1.0wt%.

[0058] The composite polyether polyol comprises polyether polyol 1 and polyether polyol 2, the hydroxyl value of polyether polyol 1 is 180mgKOH / g, the hydroxyl value of polye...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hydroxyl value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com