A kind of hips composite material and its preparation method and application

A composite material and raw material technology, applied in the field of modified plastics, can solve the problems of general heat resistance, poor barrier performance, non-antistatic, etc., and achieve the effect of good barrier grease, excellent barrier properties, and reduced surface resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-5

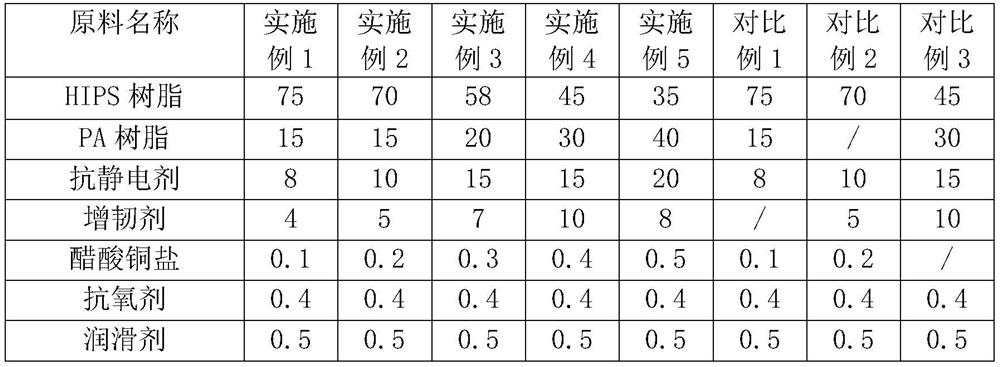

[0043] A PS composite material with high strength, high heat resistance, antistatic properties and excellent barrier properties, its raw material formula is shown in Table 1, and its preparation method includes the following steps:

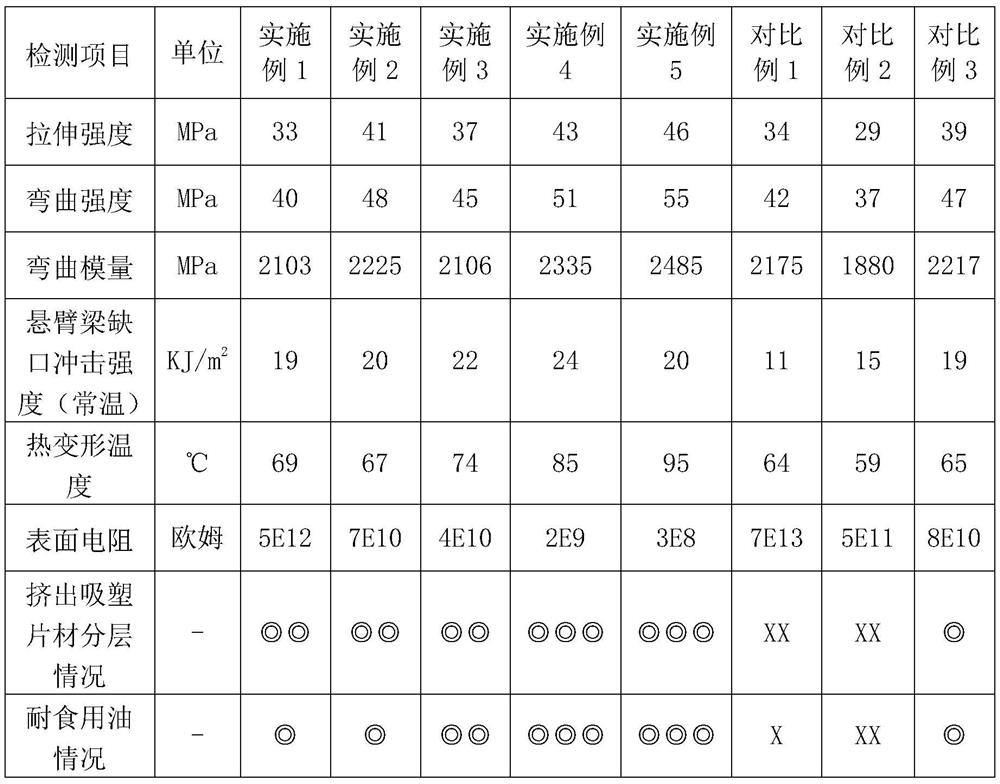

[0044] The above raw materials are uniformly mixed, and then fed from the main feeding port of the extruder. The raw materials are melted, extruded, and pelletized in the extruder to obtain PS with high strength, high heat resistance, antistatic, and excellent barrier properties. composite material; the pellets were injected into corresponding samples for testing, and the test results are shown in Table 2.

Embodiment 4

[0053] Compared with Comparative Example 3, Example 4 added copper acetate to reduce the resistance of the composite material.

Embodiment 1

[0054] Compared with Comparative Example 1, Example 1 added a toughening agent prepared from oil-extended SBS elastomer to improve the impact toughness of the composite material, and at the same time, the material could maintain better fluidity.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com