Online detection method for width of fabric

A detection method and fabric width technology, which is applied in the detection field, can solve the problems of low product precision level, low detection efficiency, uneven width, etc., and achieve the effect of high product precision level, fast and accurate detection, and stable width quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

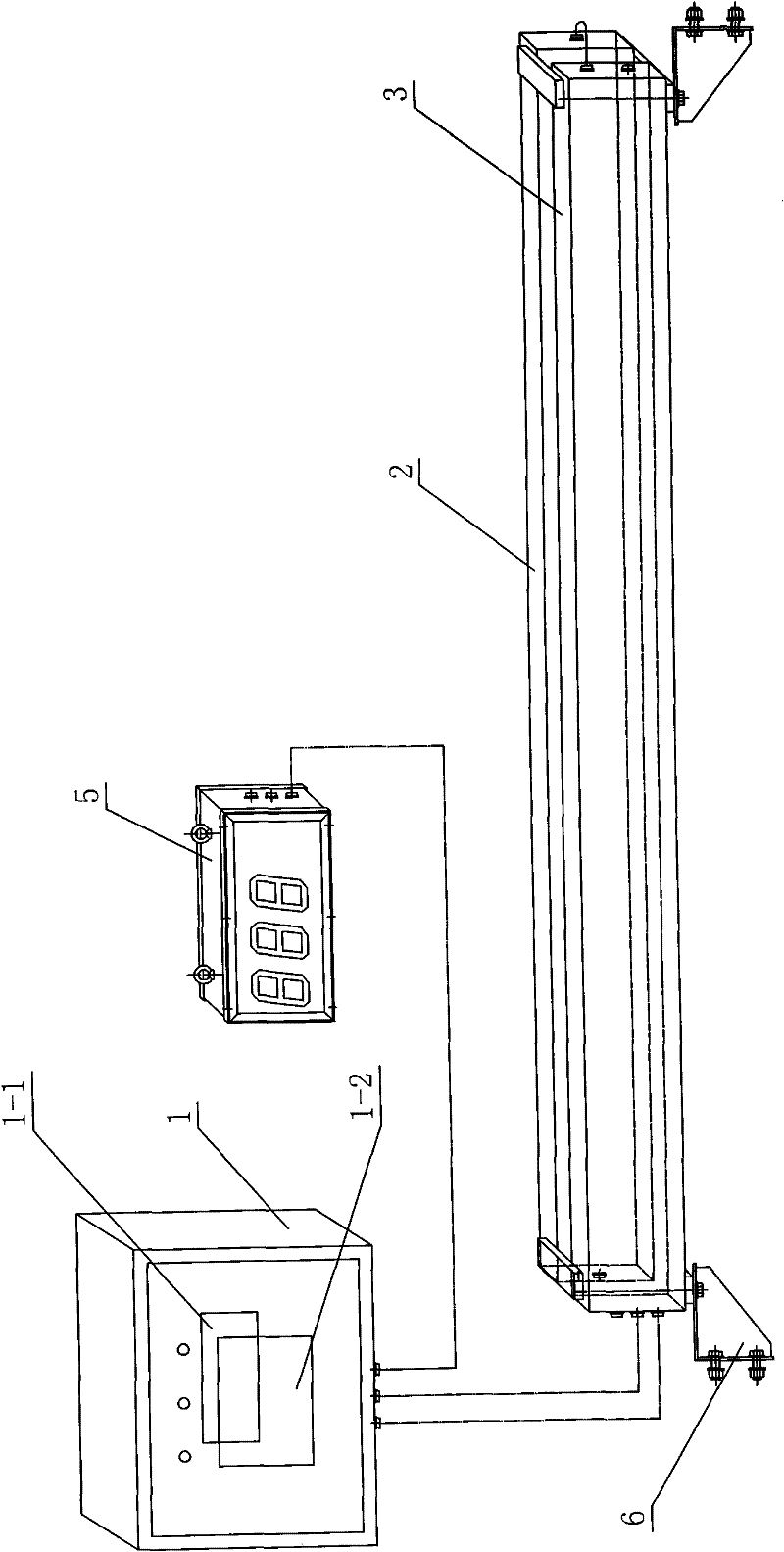

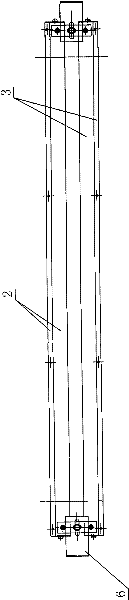

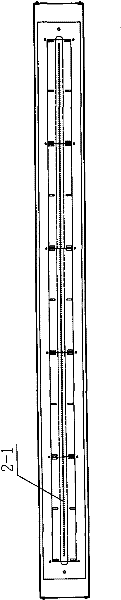

[0036] Such as Figure 1 to Figure 7 , Figure 10 , Figure 16 with Figure 17As shown, a fabric width online detection method, the detection method is as follows: one side of the fabric to be tested 7 has a group of light-emitting tubes 2-1, the other side of the fabric to be tested has a group of photosensitive elements 3-1, the group The photosensitive element 3-1 is composed of a row of photosensitive elements 3-1, the total width P of the group of photosensitive elements 3-1 is greater than the width L of the fabric to be measured, and the center distance between adjacent photosensitive elements 3-1 is known, S is the center-to-center distance of adjacent photosensitive elements 3-1, the center-to-center distance S of adjacent photosensitive elements 3-1 in the group of photosensitive elements 3-1 is equal, and the center-to-center distance S of adjacent photosensitive elements 3-1 is set to 3 mm. The photosensitive elements 3-1 located in the width region of the fabri...

Embodiment 2

[0040] like Figure 1 to Figure 6 , Figure 8 , Figure 11 , Figure 16 and Figure 17 As shown, a fabric width online detection method, the detection method is as follows: one side of the fabric to be tested 7 has a group of light-emitting tubes 2-1, the other side of the fabric to be tested has a group of photosensitive elements 3-1, the group The photosensitive element 3-1 is composed of two rows of photosensitive elements 3-1, the total width P of the group of photosensitive elements 3-1 is greater than the width L of the fabric to be measured, and the center distance between adjacent photosensitive elements 3-1 is known, S is the center-to-center distance of adjacent photosensitive elements 3-1, the center-to-center distance S of adjacent photosensitive elements 3-1 in the group of photosensitive elements 3-1 is equal, and the center-to-center distance S of adjacent photosensitive elements 3-1 is set to 8mm. The photosensitive element 3-1 in the fabric width area is s...

Embodiment 3

[0043] like Figure 1 to Figure 6 , Figure 9 , Figure 12 , Figure 16 and Figure 17 As shown, a fabric width online detection method, the detection method is as follows: one side of the fabric to be tested 7 has a group of light-emitting tubes 2-1, the other side of the fabric to be tested has a group of photosensitive elements 3-1, the group The photosensitive element 3-1 is composed of three rows of photosensitive elements 3-1, the total width P of the group of photosensitive elements 3-1 is greater than the width L of the fabric to be measured, and the center distance between adjacent photosensitive elements 3-1 is known, S is the center-to-center distance of adjacent photosensitive elements 3-1, the center-to-center distances of adjacent photosensitive elements in the group of photosensitive elements are not equal, and the center-to-center distance of adjacent photosensitive elements 3-1 is set to be 1 mm to 10 mm. The photosensitive elements 3-1 located in the widt...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com