Lead sag monitoring device

A technology for monitoring device and wire sag, which is applied in the direction of measuring device, optical device, instrument, etc., can solve the problems of large error, the temperature of wire is easily affected by environmental factors, and it is difficult to find problems, so as to improve the measurement accuracy and avoid Effects of environmental factor error and efficiency improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

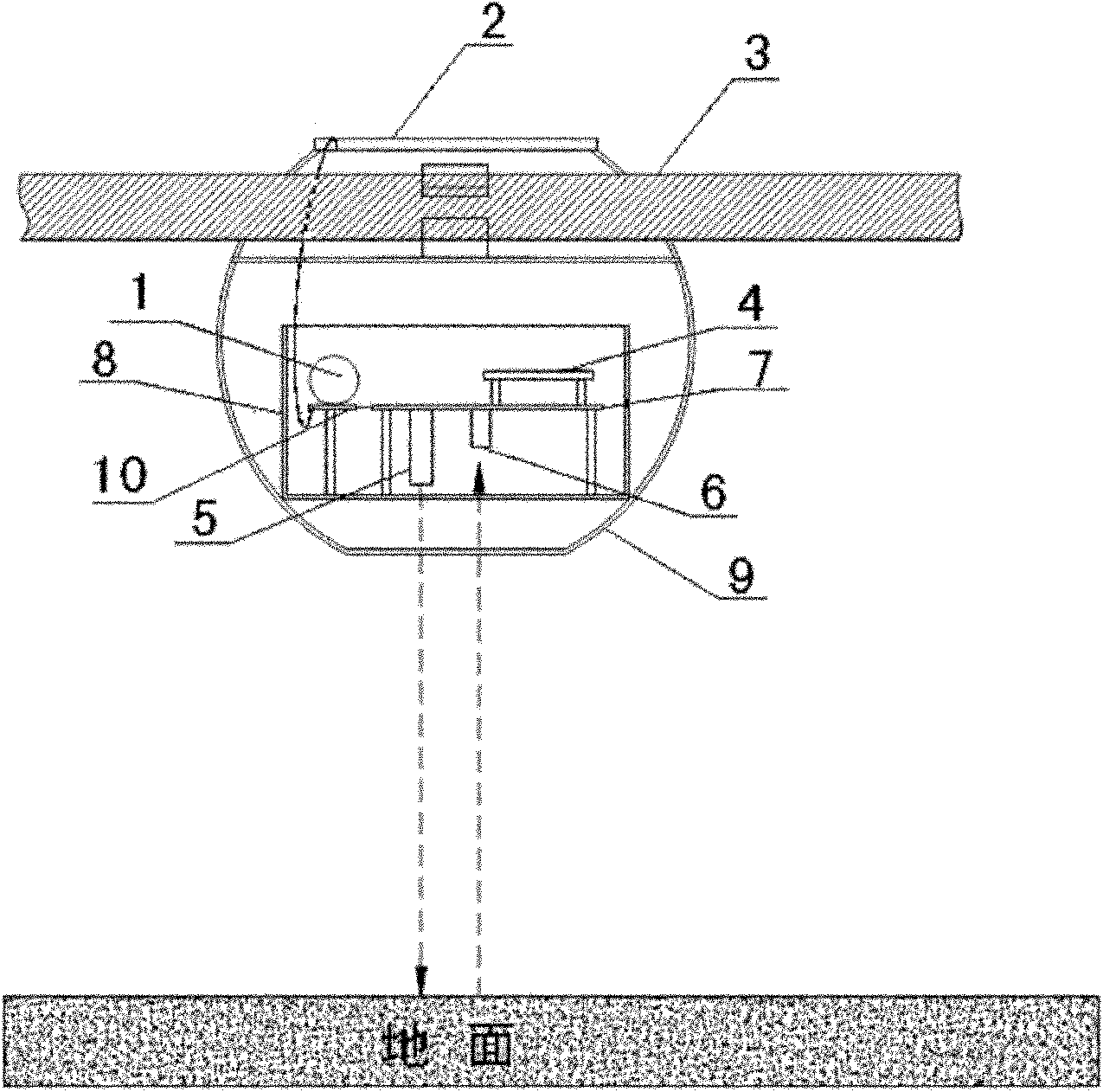

[0025] Specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

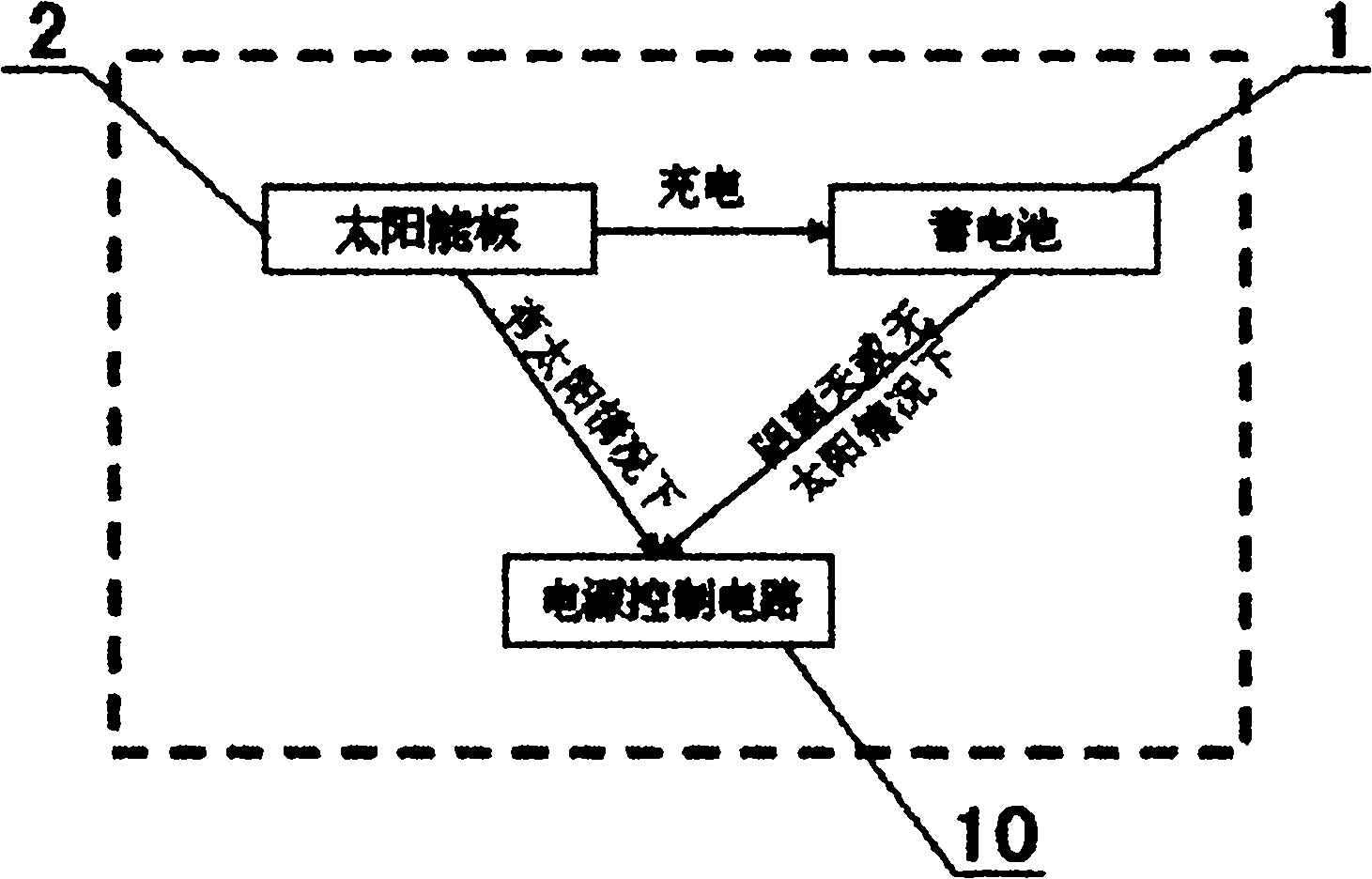

[0026] A wire sag monitoring device, including a semiconductor laser 5, a photoelectric receiver 6, a laser drive and receiving amplification counting circuit board 7, is characterized in that:

[0027] The laser driving circuit and the receiving, amplifying and counting circuit board 7 are fixedly installed in the first installation box 8 .

[0028] The semiconductor laser 5 is installed in the first installation box 8 through a screw card, and is connected with the laser driving and receiving amplification counting circuit board 7 for emitting laser light.

[0029] The photoelectric receiver 6 is mounted on the laser driving circuit and the receiving amplification counting circuit board 7 for receiving reflected laser light.

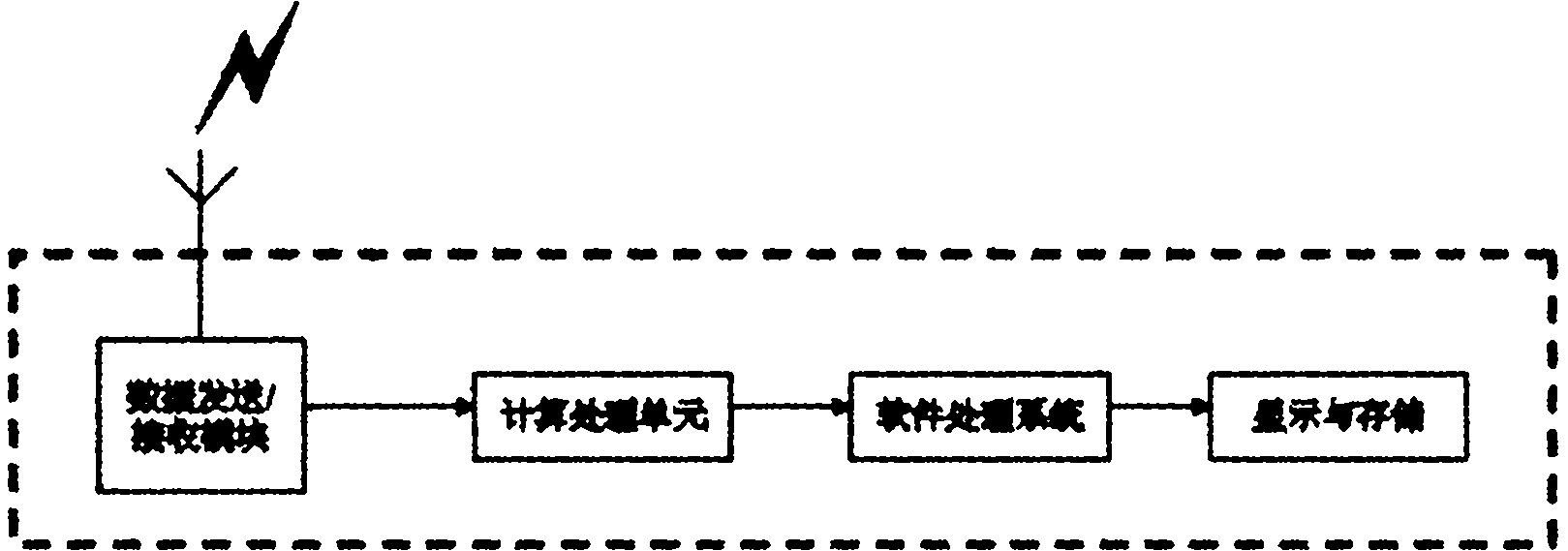

[0030] The wireless communication module 4 is installed on the laser driving circuit and the receiving, amplifying ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com