Rapid calibration device and method based on multi-edge drill rod

A calibration device and drill pipe technology, which is applied in the direction of drill pipe, drill pipe, earthwork drilling, etc., can solve the problems of poor universality and versatility, huge labor cost, and failure of the calibration process, so as to improve the carrying capacity and shorten the Interval time, time-saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

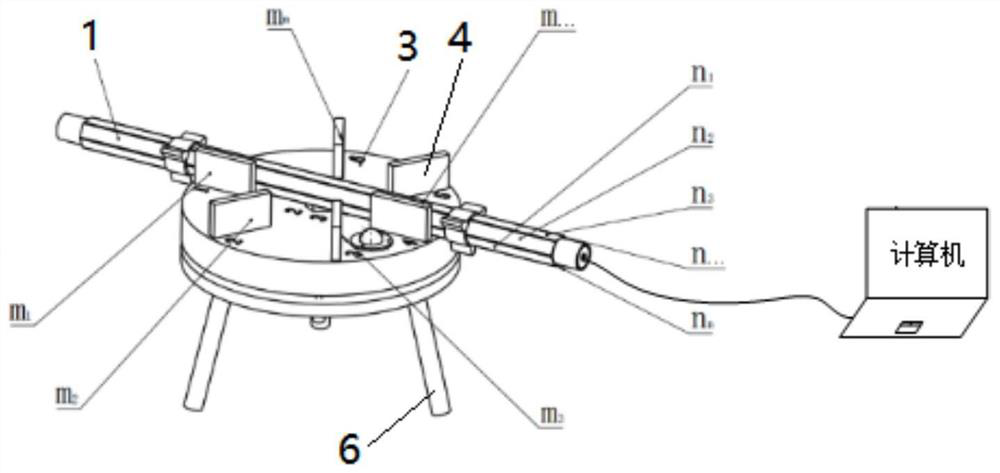

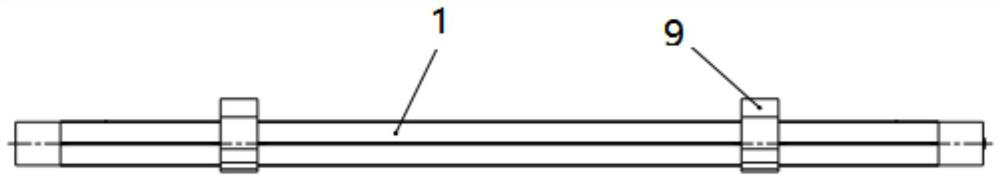

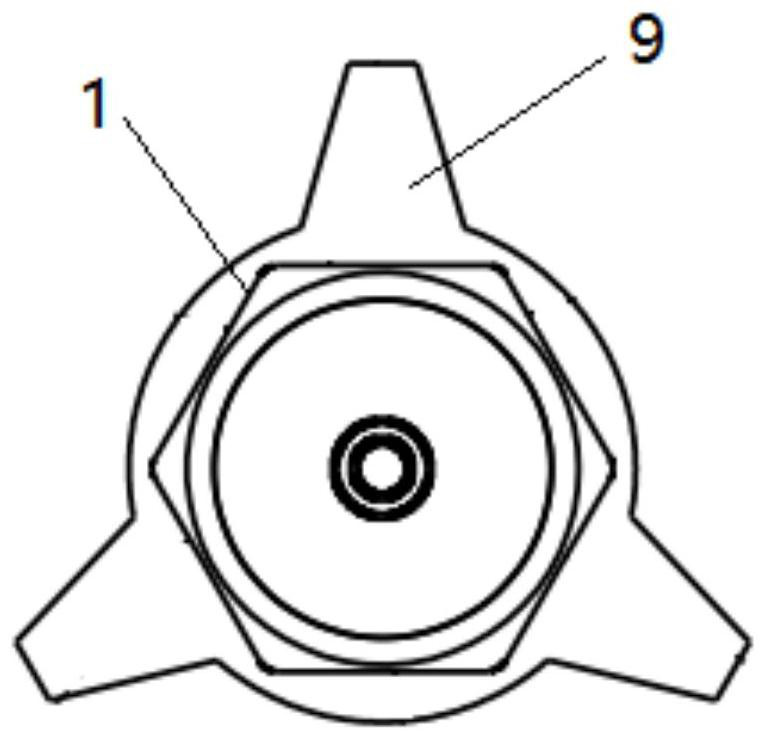

[0087] This embodiment discloses a rapid calibration device based on a multi-edge drill pipe, such as Figure 1-7 As shown, it includes a drill pipe 1 and a computer, the drill pipe 1 is embedded with a data acquisition circuit 2, and the embedded data acquisition circuit (2) is electrically connected with the computer. The number of edges of 1 is n, and the rapid calibration device further includes: a disk 3, and a plurality of first baffles 4 are arranged on the disk 3 along its circumferential direction, and each of the first baffles 4 is along the diameter of the disk 3. The length of each first baffle plate 4 is smaller than the radius of the disc 3, the first baffle plate 4 divides the disc 3n into equal parts, and the disc 3 is also provided with a polygonal through hole 5 , the central axis of the polygonal through hole 5 is collinear with the central axis of the disk 3 , the number of edges of the polygonal through hole 5 is n, and the polygonal through hole 5 is in p...

Embodiment 2

[0094] This embodiment discloses a rapid calibration method based on a multi-edge drill pipe. The method adopts the calibration device of Embodiment 1, such as Figure 1-7 As shown in the figure, the drill pipe is hexagonal, and each face of the drill pipe has an independent plane number, which is marked with numbers 1 to 6 in turn. In order to ensure the accuracy of the calibration results, the hexagonal edge of the drill pipe is required to maintain a certain For levelness and machining accuracy, the first baffle divides the disk into 6 equal parts, among which, based on the true north index line, the first baffle is set at every 60° interval in a counterclockwise order to form six equal-area areas. Each area has an independent area number, numbered from 1 to 6, and each first baffle is divided into two sides, A and B; The hexagonal shape formed by a baffle plate and the hexagonal through hole are arranged symmetrically to the center, and the size of the hexagonal through ho...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com