Ultra-large type geotechnical engineering three-dimensional model test system

A geotechnical engineering and three-dimensional model technology, applied in the direction of applying stable tension/pressure to test the strength of materials, instruments, and measuring devices, can solve the problems of single function of the device, cumbersome adjustable operation, low stiffness and strength, etc. Achieve the effect of high degree of visualization, convenient installation and disassembly, high rigidity and strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

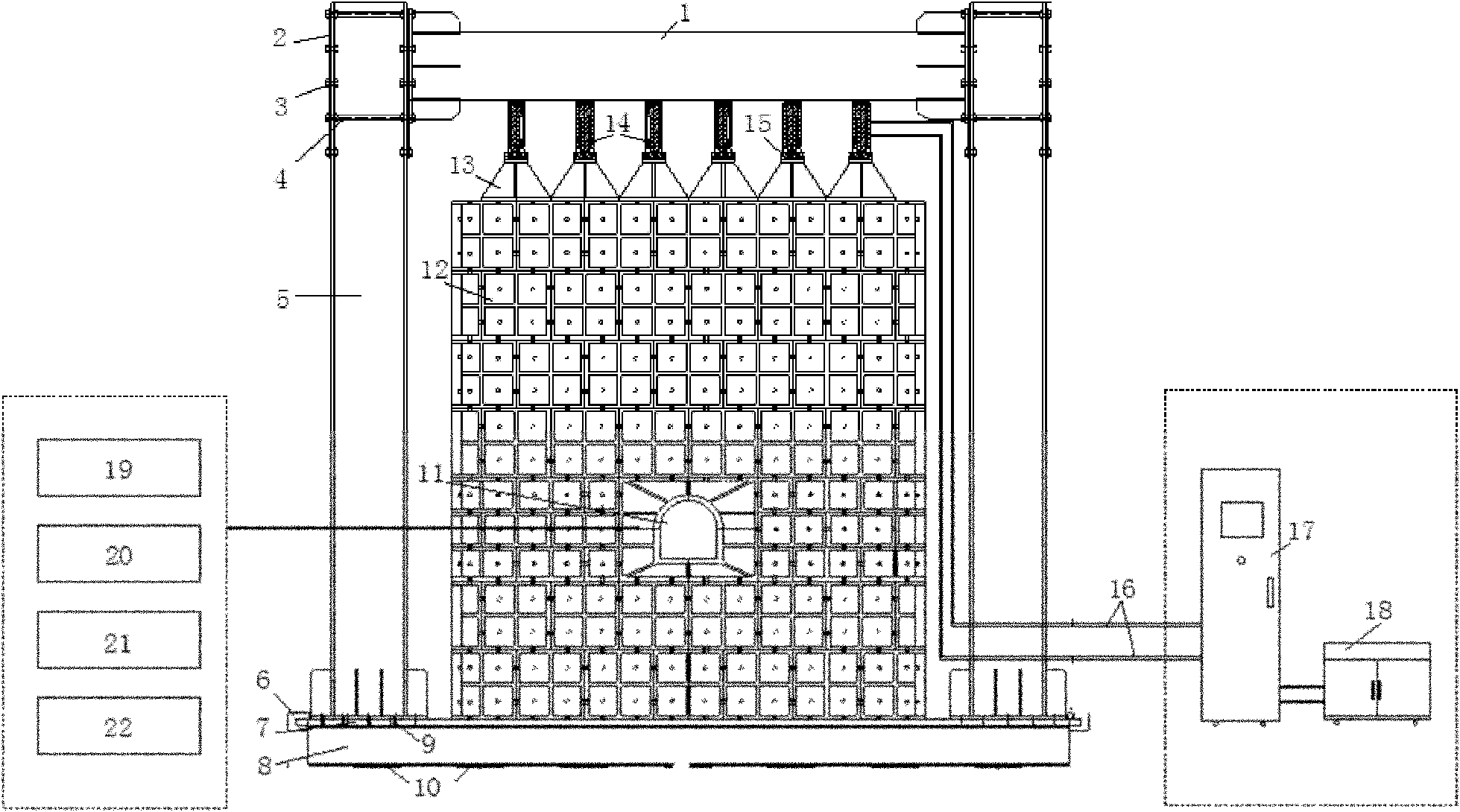

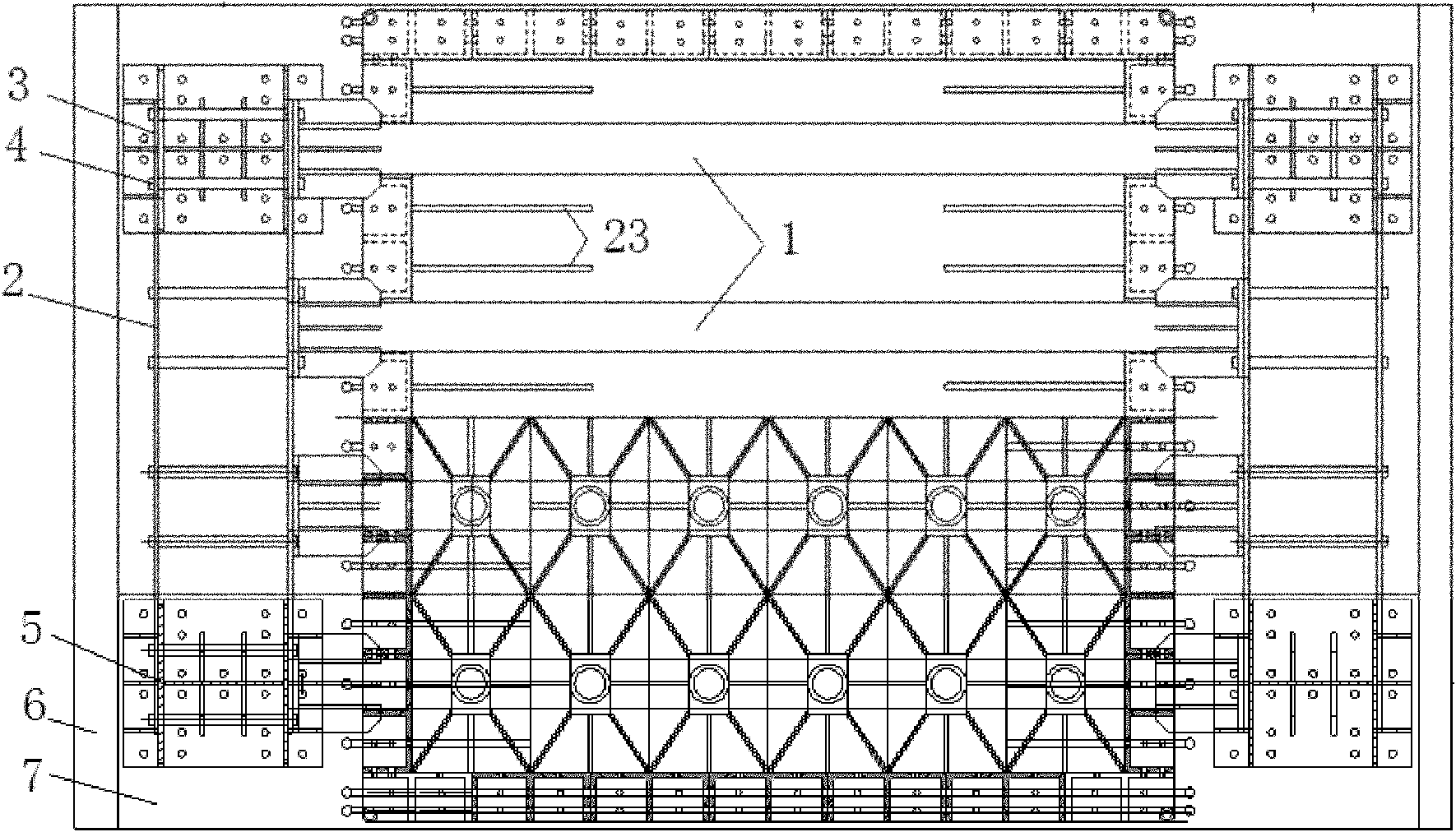

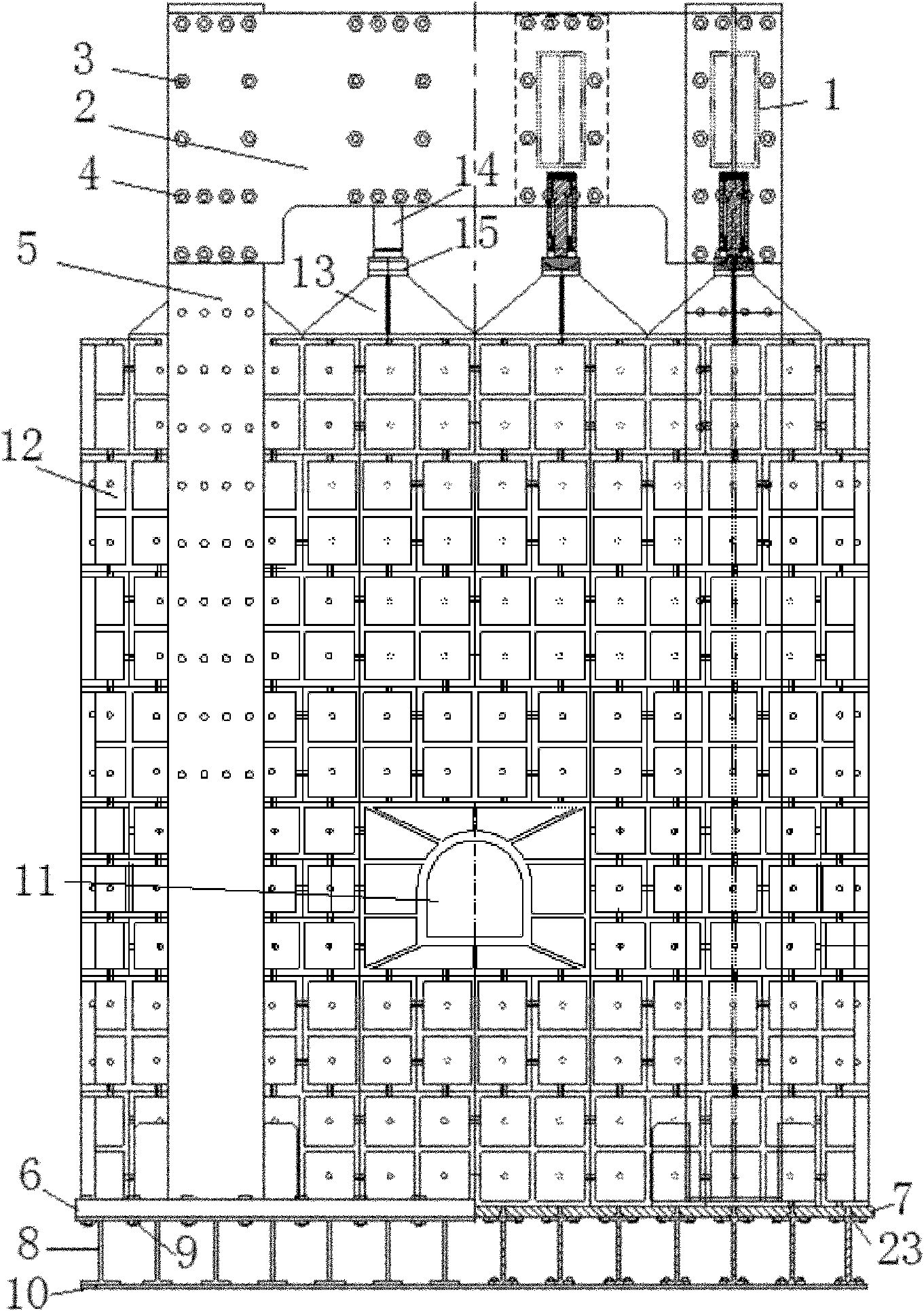

[0046] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

[0047] Such as Figure 1-3 As shown, a super-large geotechnical engineering three-dimensional model test system includes a super-large model test device, a hydraulic loading system and a strain displacement test system respectively connected to the large-scale model test device. The super-large model test device includes a portal frame , the lower end of the portal frame is set on the base plate device, and the base plate device is provided with a model reaction wall 12 located at the lower part of the portal frame; a strain displacement testing system is installed on the model reaction wall 12 .

[0048] The portal frame includes two pairs of uprights 5 symmetrically arranged on the left and right, and the inner and outer sides of the two uprights 5 on the same side are connected by two crossbeam upright connecting plates 2 , and the inner and outer si...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com