Metal magnetic memory signal acquisition device for R-angle position of waste crankshaft before remanufacturing

A metal magnetic memory and signal acquisition technology, applied in the direction of material magnetic variables, etc., can solve the problems such as the inability to adjust the arc surface freely, the poor adaptability of small crankshafts, and the difficulty of deep penetration.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

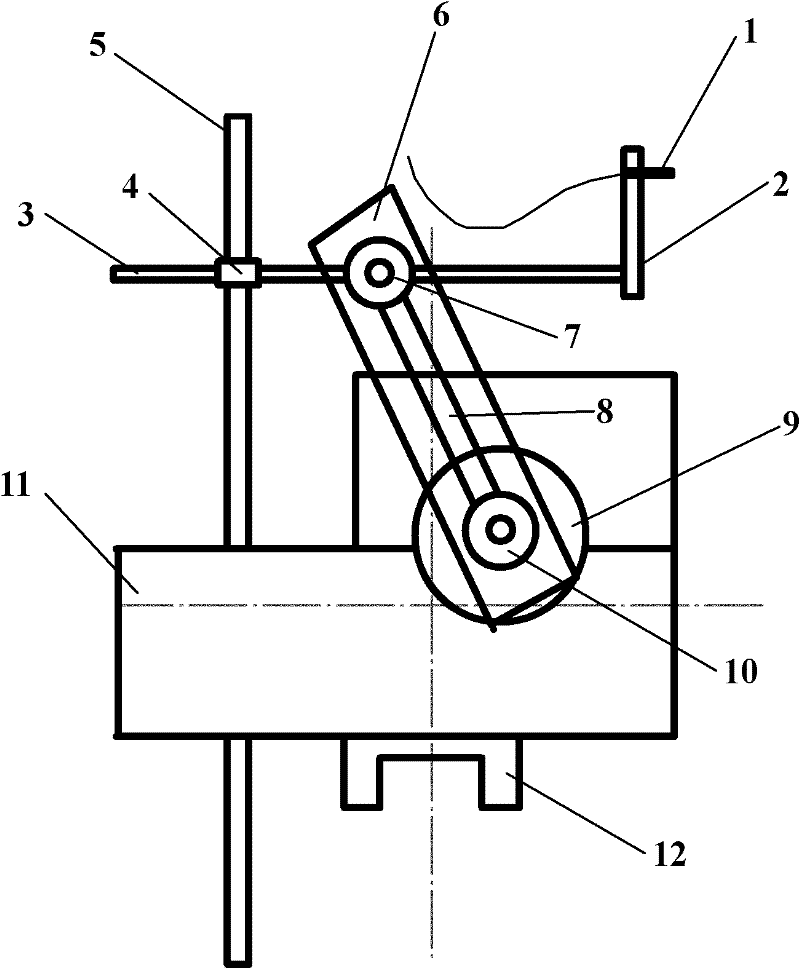

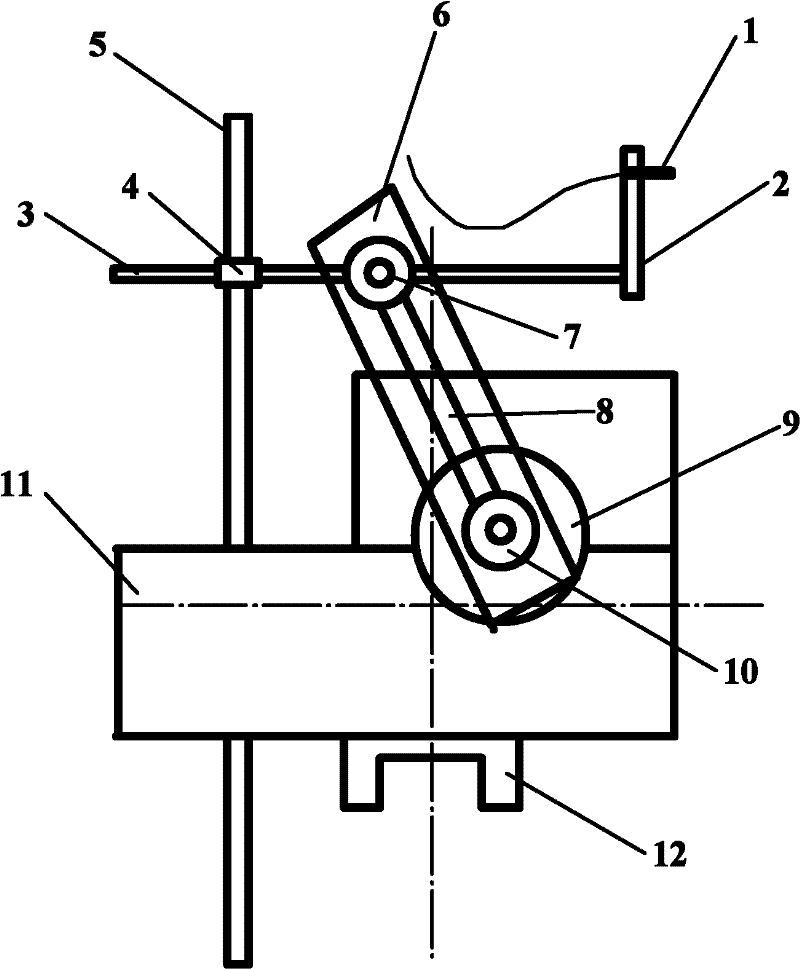

[0021] The content of the present invention will be described in detail below with reference to the drawings and embodiments. In the specific implementation, the crankshaft to be detected is a heavy-duty automobile Steyr engine crankshaft.

[0022] 1. Adjust the distance between the center of the one-way slider 7 and the center of the ball spline shaft 9 to make it equal to the eccentric distance between the main journal axis of the Steyr-type crankshaft and the connecting rod journal axis;

[0023] 2. Adjust the phase of the ball spline shaft 9 to 120° to make it the same phase as the third connecting rod journal of the crankshaft to be tested;

[0024] 3. Install the metal magnetic memory signal probe 1 in the fixture 2;

[0025] 4. Move the guide sleeve 12 to the corner R of the third connecting rod journal of the crankshaft to be detected;

[0026] 5. Adjust fixture 2 to make the probe vertical R angle and maintain a fixed lift-off value of 1mm;

[0027] 6. Rotate the ball spline sh...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com