Method and device for detecting defects and failures of high-speed rail based on vibration signals

A technology of vibration signal and detection method, which is applied in processing the response signal of detection and analyzing solids using sonic/ultrasonic/infrasonic waves, which can solve problems such as affecting the efficiency of train operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

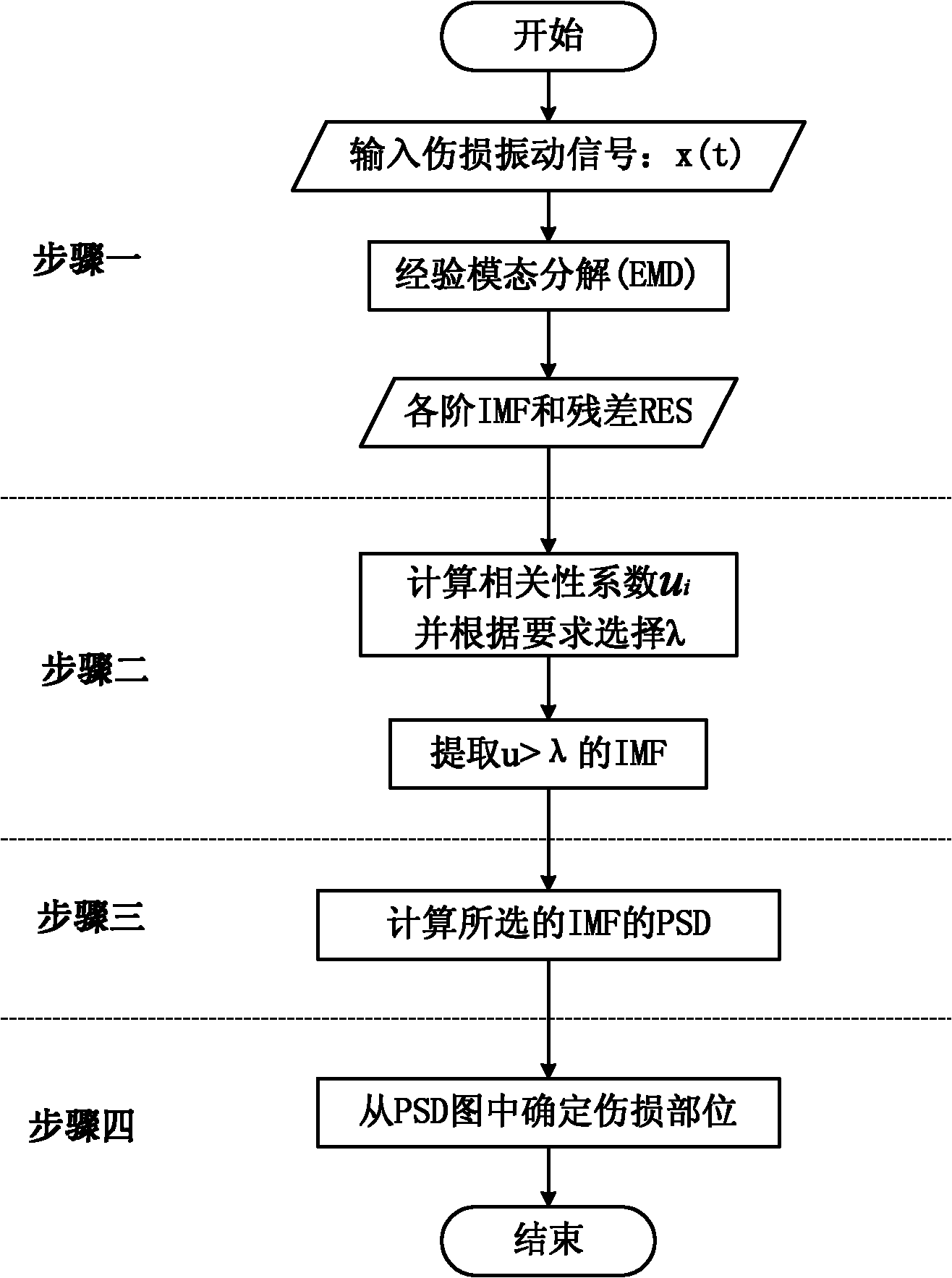

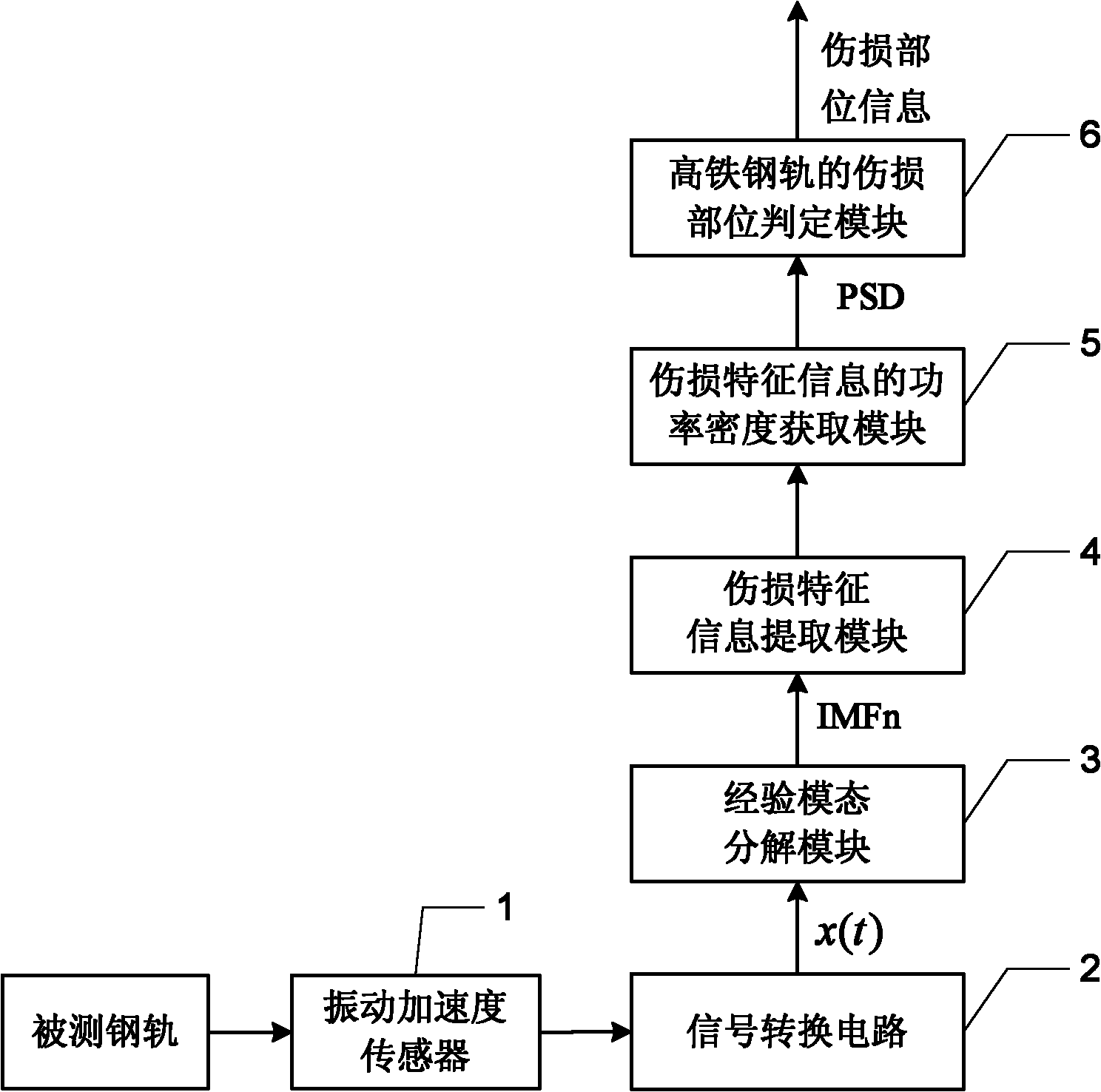

[0026] Specific implementation mode one: the following combination figure 1 , figure 2 and Figure 5 To illustrate this embodiment, the present invention adopts a new high-speed train damage detection method based on vibration signal feature extraction, aiming at the fact that the existing flaw detection technology and flaw detection mechanism cannot meet the flaw detection requirements of high-speed railways. By establishing a corresponding track damage detection sensor network along the railway line, the rail vibration signal is measured, and the signal is preprocessed and sent to the flaw detection vehicle or a specific information center; after the flaw detection vehicle or information center receives the signal, it uses the empirical model State decomposition (EMD) decomposes the received vibration signal to obtain the corresponding internal solid mode function (IMF). The obtained IMF components of each order contain the characteristic information of rail damage (the ch...

specific Embodiment approach 2

[0037] Specific implementation mode two: the following combination Figure 4 Illustrate this embodiment, this embodiment will further explain Embodiment 1: in the step 1, collect the vibration signal of the high-speed rail rail by the vibration acceleration sensor, the vibration acceleration sensor is arranged on the rail bottom upper surface of the high-speed rail rail, and the distance from the rail bottom outer edge d In terms of distance, the value range of d is 18mm-20mm.

specific Embodiment approach 3

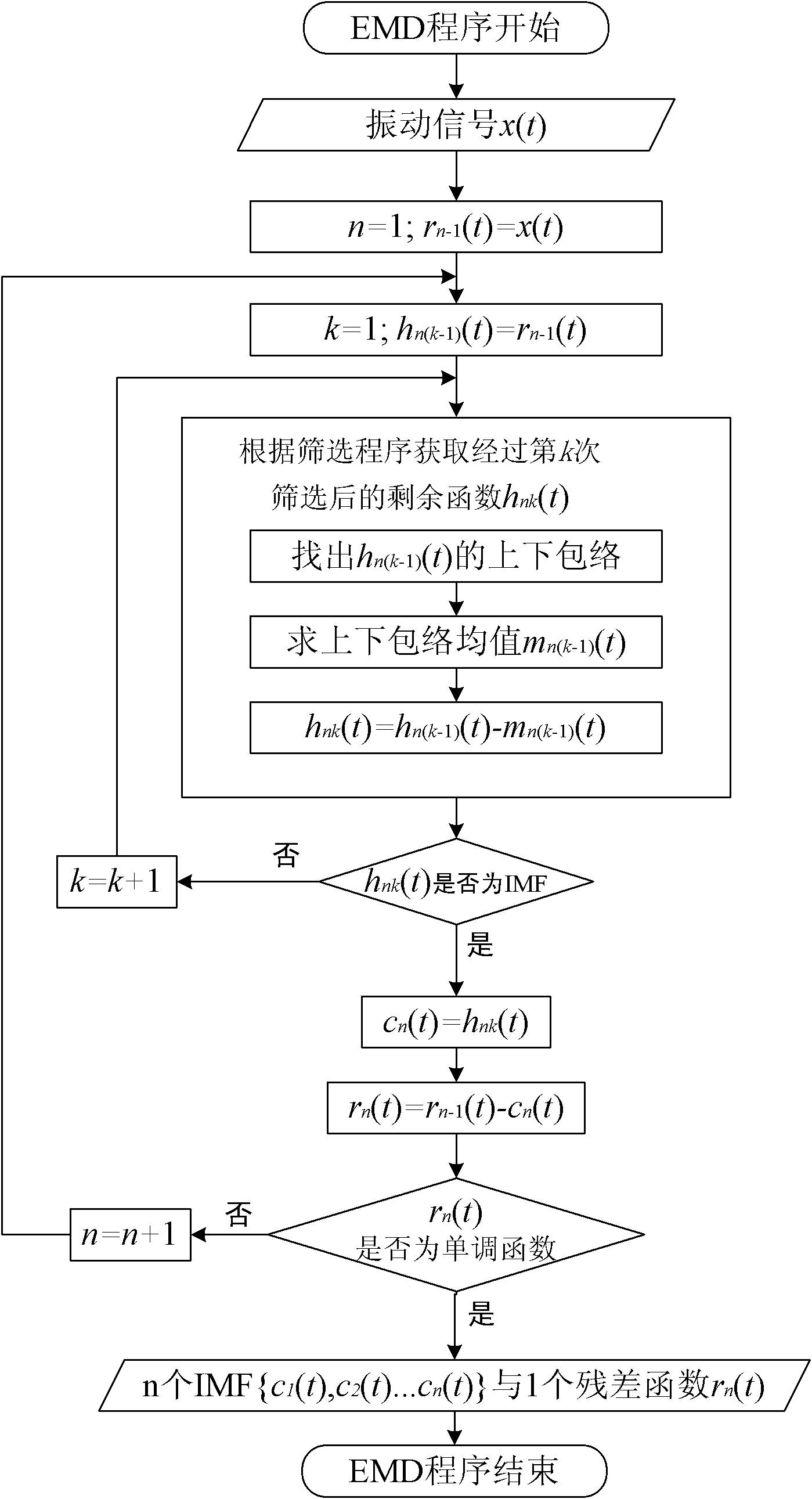

[0038] Specific implementation mode three: the following combination image 3 Describe this embodiment, this embodiment will further explain Embodiment 1: the process of obtaining n IMF components and a residual in step 1 is:

[0039] Set the input damage vibration signal as x(t), t=1, 2,..., N,

[0040] Step 11, IMF decomposition process initialization: n=1, and satisfy the relation r n-1 (t)=x(t) holds, where r n-1 (t) is the trend function after the (n-1)th decomposition;

[0041] Step 12: Initialize the screening process, k=1, and satisfy the relation hn(k-1) (t)=r n-1 (t) holds, where h n(k-1) (t) is the residual function after the (k-1)th screening in the nth empirical mode decomposition;

[0042] Step 13. Obtain the remaining function h after the kth screening according to the screening program nk (t);

[0043] Step 14, using the standard deviation criterion to judge the remaining function h obtained in step 13 nk (t) Whether the condition of the intrinsic mode ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com