Connecting method for detachable conductor connector

A connection method and connector technology, which is applied in the manufacture of cables/conductors, insulation of conductors/cables, power cables, etc., can solve the problems of scrapped cable insulated cores, scrapped insulated cores, etc., to reduce the number of shutdowns and save waste , the effect of improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

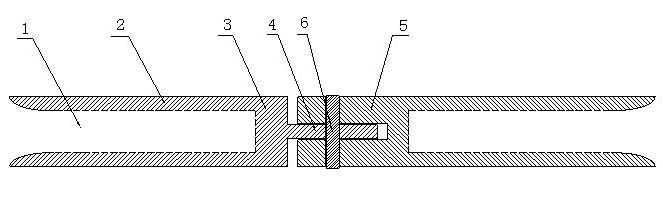

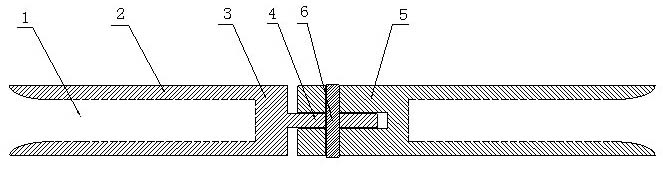

[0015] Such as figure 1 As shown, the detachable conductor connector of the present invention mainly includes two components of an upper connecting sleeve and a lower connecting sleeve, both of which are hollow cylindrical sleeves with single-end closure, and the cylindrical sleeve The tube is composed of a solid cylindrical closed end 3 and a sleeve wall 2 formed in the axial direction. The inner cavity surrounded by the sleeve wall 2 is the crimping area 1 where the conductor is inserted. The upper and lower connecting sleeves are closed along the solid cylinder. On the other side of the end 3, a protruding connecting end 4 and a groove connecting end 5 are respectively formed which match each other, and a central connecting pin hole is arranged radially on the protruding connecting end 4 and the groove connecting end 5, and a connecting pin 6 is inserted therein.

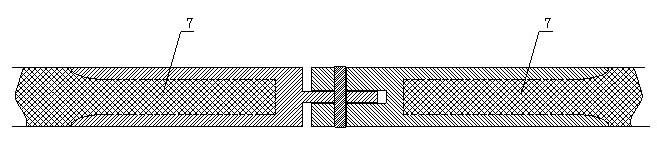

[0016] Attached below figure 2 A further explanation will be given to the method for implementing the connec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com