Gadolinium-gold composite silicone nanomaterial and preparation method and application thereof

A nanomaterial, silicon nanotechnology, applied in the field of medical materials, to achieve the effect of enhancing relaxation rate and enhancing paramagnetism

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

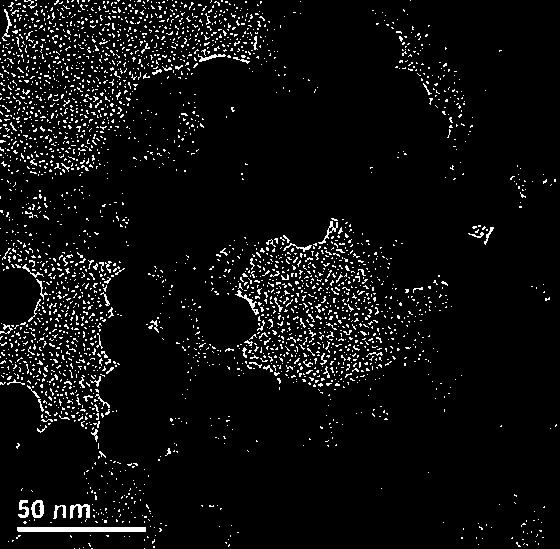

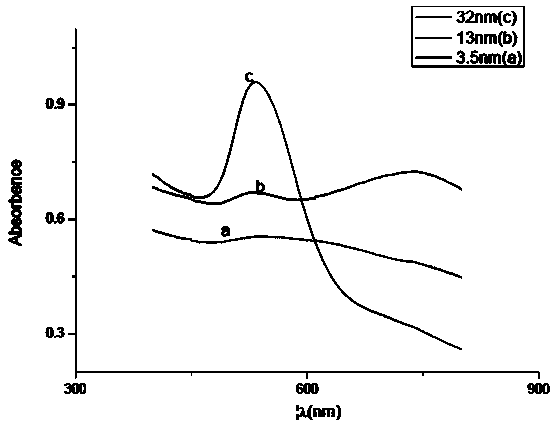

[0040] Gd-MCM-41 with 23nm colloidal gold particles was synthesized using cetyltrimethylbromide (CTAB) as a template, tetraethyl orthosilicate as a silicon source, and polyethyleneimine as a polymer modifier.

[0041] Dissolve cetyltrimethylbromide (CTAB) in 80mL of deionized water, add ammonia solution with a mass concentration of 25%, stir and dissolve at room temperature, add polyethylene glycol 4000, continue to stir and dissolve; Ethyl silicate was slowly added dropwise to the above solution, and then GdCl was added under ultrasonic vibration 3 ·6H 2 O, the reaction time is 1.0 h; the solid is collected, washed with absolute ethanol three times, freeze-dried, and calcined at 550° C. for 5.0 h to obtain Gd-MCM-41.

[0042] HAuCl with a mass concentration of 1% 4 Dissolve in 100mL of deionized water, heat to boiling, quickly add 1.5mL of trisodium citrate with a mass concentration of 1%, boil for 10min, leave to cool at room temperature, and obtain colloidal gold particl...

Embodiment 2

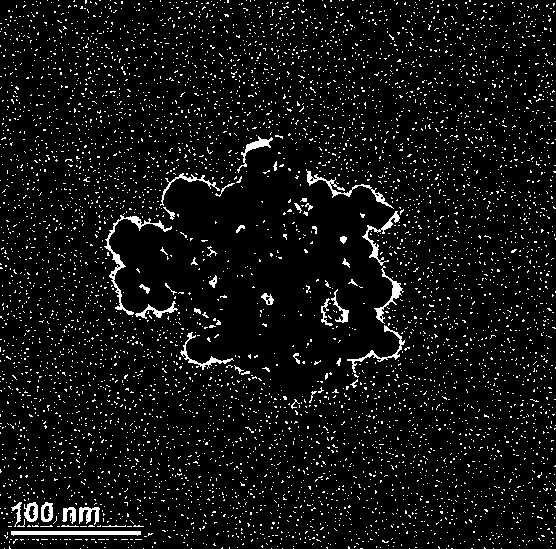

[0044] Gd-MCM-41 with 13nm colloidal gold particles was synthesized using cetyltrimethylbromide (CTAB) as a template, tetraethyl orthosilicate as a silicon source, and polyvinylamide as a polymer modifier.

[0045] Dissolve cetyltrimethylbromide (CTAB) in 80mL of deionized water, add ammonia solution with a mass concentration of 25%, stir and dissolve at room temperature, add polyethylene glycol 4000, continue to stir and dissolve; Ethyl silicate was slowly added dropwise to the above solution, and then GdCl was added under ultrasonic vibration 3 ·6H 2 O, the reaction time is 1.0 h; the solid is collected, washed with absolute ethanol three times, freeze-dried, and calcined at 500° C. for 5.0 h to obtain Gd-MCM-41.

[0046] HAuCl with a mass concentration of 1% 4 Dissolve in 100mL of deionized water, heat to boiling, quickly add 10mL of 1% trisodium citrate, boil for 7min, leave to cool at room temperature, and obtain colloidal gold particles with a particle size of 13nm. ...

Embodiment 3

[0048] Using cetyltrimethylbromide (CTAB) as a template, tetraethyl orthosilicate as a silicon source, and polypropylene-methacrylic acid as a polymer modifier to synthesize Gd-MCM-41 with 5nm colloidal gold particles .

[0049] Dissolve cetyltrimethylbromide (CTAB) in 80mL of deionized water, add ammonia solution with a mass concentration of 25%, stir and dissolve at room temperature, add polyethylene glycol 6000, continue to stir and dissolve; Ethyl silicate was slowly added dropwise to the above solution, and then GdCl was added under ultrasonic vibration 3 ·6H 2 O, reaction time 1.0h; collect the solid, wash with absolute ethanol three times, freeze-dry, and calcinate at 450°C for 5.0h to obtain Gd-MCM-41.

[0050] At 4°C, add 1% HAuCl 4 Dissolve in 150mL of deionized water, add 0.4mL of 0.2mol / L K 2 CO 3 solution, adjust the pH to neutral, then add 2.4 mL of 0.5 mg / mL NaBH4 solution prepared with ice water, and stir for 1.0 min to obtain colloidal gold particles wit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com