Process for performing casting under negative pressure condition

A technology of casting process and conditions, applied in the field of casting, can solve problems such as difficulty in filling, non-empty cavity, and impact on the quality of castings

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

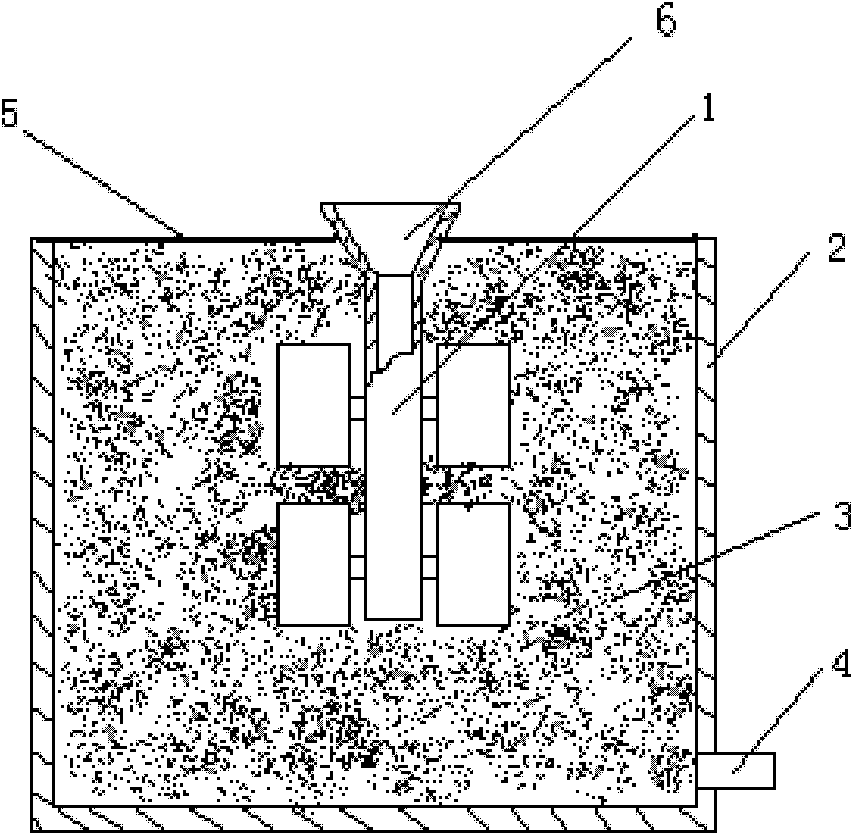

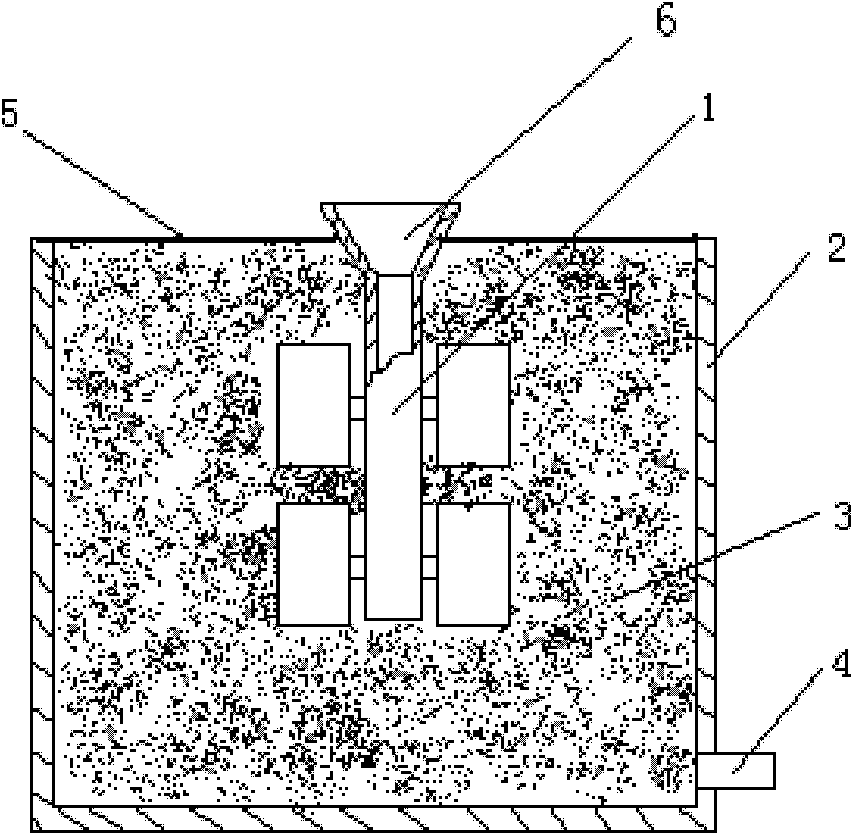

[0011] As shown in the accompanying drawings, the casting process method under the negative pressure condition of the present embodiment, at first prepare the shell 1 with the gate 6 by the investment casting method, and the shell 1 is baked to the predetermined time for 30 minutes to the predetermined time. After the calcination temperature is 1050°C, cool to room temperature and then put it into the heat-resistant flask 2 with the air outlet 4, or place the mold shell 1 prepared by investment casting method directly in the heat-resistant flask with the air outlet 4 2, fill the gap between the shell 1 and the heat-resistant sand box 2 with refractory heat-insulating sand 3, cover the surface of the refractory heat-insulation sand 3 with a heat-resistant sealing layer 5 with a preset thickness, and seal the gate of the shell 1 6. The upper part is exposed on the heat-resistant sealing layer 5. Such mold shell 1, heat-resistant sand box 2, refractory insulating sand 3 and heat-r...

Embodiment 2

[0013] As shown in the accompanying drawings, the casting process method under the negative pressure condition of the present embodiment, at first prepare the shell 1 with the gate 6 by the investment casting method, and the shell 1 is baked to the predetermined time for 30 minutes to the predetermined time. After the calcination temperature is 1050°C, cool to room temperature and then put it into the heat-resistant flask 2 with the air outlet 4, or place the mold shell 1 prepared by investment casting method directly in the heat-resistant flask with the air outlet 4 2, fill the gap between the shell 1 and the heat-resistant sand box 2 with refractory heat-insulating sand 3, cover the surface of the refractory heat-insulation sand 3 with a heat-resistant sealing layer 5 with a preset thickness, and seal the gate of the shell 1 6. The upper part is exposed on the heat-resistant sealing layer 5. Such mold shell 1, heat-resistant sand box 2, refractory insulating sand 3 and heat-r...

Embodiment 3

[0015] As shown in the accompanying drawings, the casting process method under the negative pressure condition of the present embodiment, at first prepare the shell 1 with the gate 6 by the investment casting method, and the shell 1 is baked to the predetermined time for 30 minutes to the predetermined time. After the calcination temperature is 1050°C, cool to room temperature and then put it into the heat-resistant flask 2 with the air outlet 4, or place the mold shell 1 prepared by investment casting method directly in the heat-resistant flask with the air outlet 4 2, fill the gap between the shell 1 and the heat-resistant sand box 2 with refractory heat-insulating sand 3, cover the surface of the refractory heat-insulation sand 3 with a heat-resistant sealing layer 5 with a preset thickness, and seal the gate of the shell 1 6. The upper part is exposed on the heat-resistant sealing layer 5. Such mold shell 1, heat-resistant sand box 2, refractory insulating sand 3 and heat-r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com