Indexing positioning right-angle milling head

An indexing positioning, right-angle technology, applied in the direction of precision positioning equipment, metal processing mechanical parts, driving devices, etc., can solve the problems of key block wear, low indexing accuracy, low processing efficiency, etc., to eliminate axial displacement, extend Service life and the effect of improving processing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

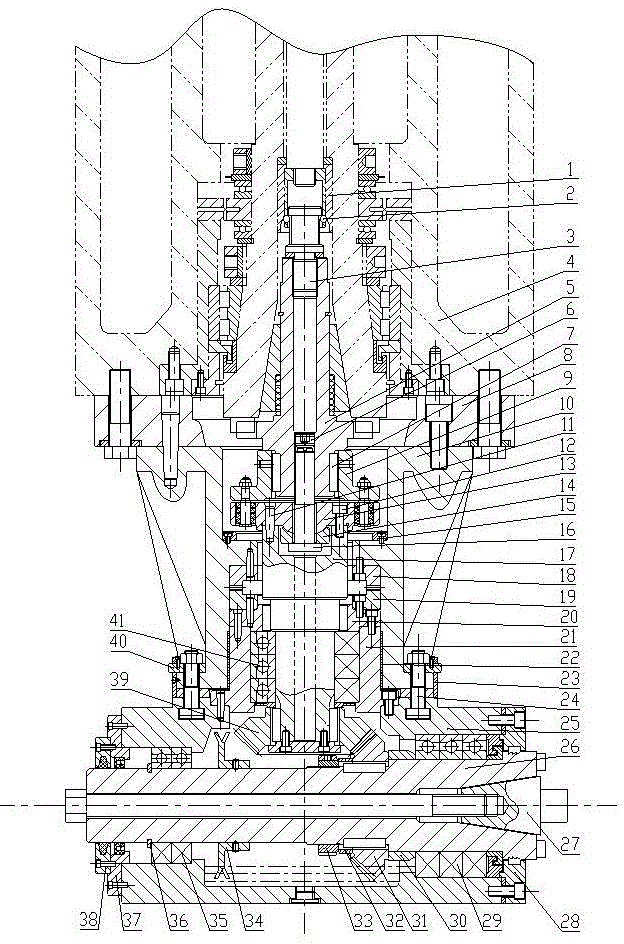

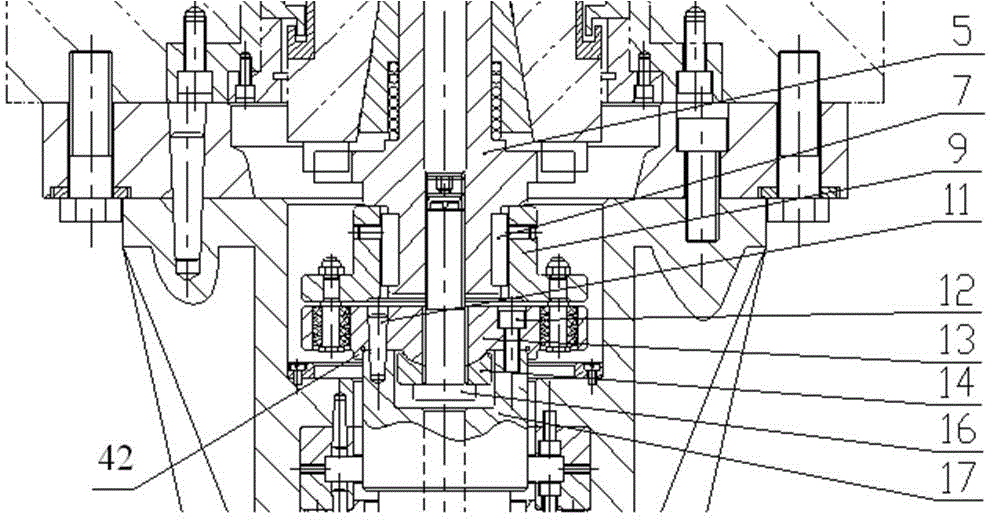

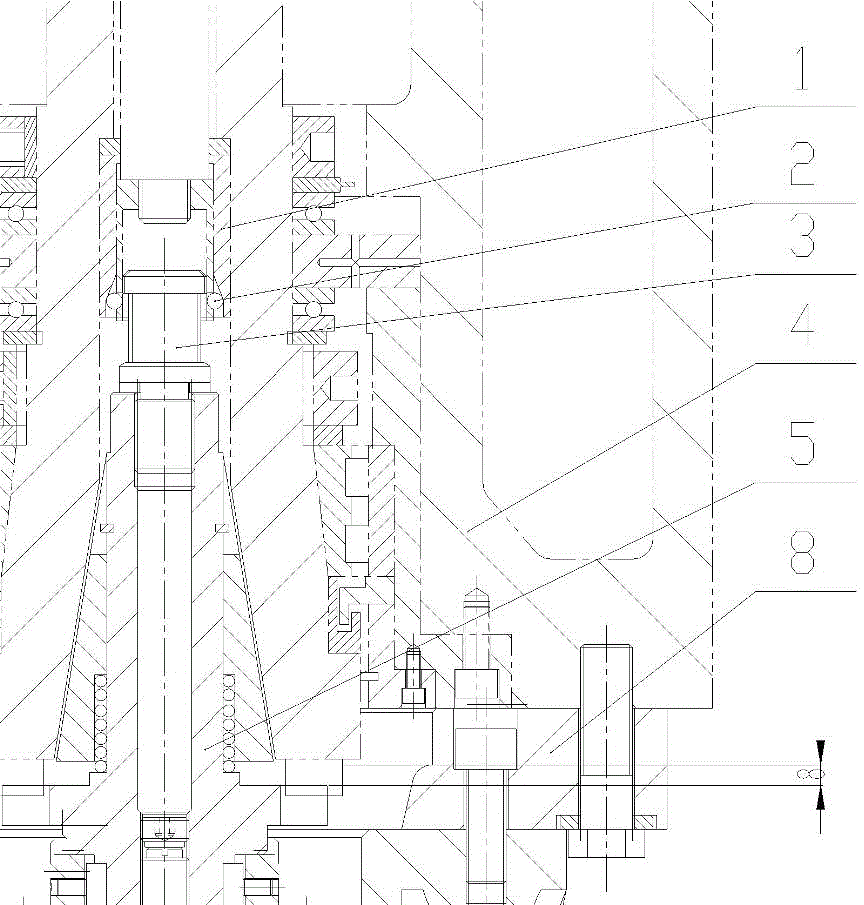

[0049] The specific implementation of the indexing and positioning right-angle milling head of the present invention will be described in detail below in conjunction with the accompanying drawings.

[0050] See attached figure 1 , an indexing and positioning right-angle milling head, including a housing, a vertical shaft, a bevel gear set, and a horizontal shaft. The housing includes a vertical shaft housing 10 and a horizontal shaft housing 25. The vertical shaft is installed in the vertical shaft housing 10 through a ball bearing 41 and a bearing seat 21. The vertical shaft bevel gear 39 is connected with the vertical shaft. The horizontal shaft 26 is connected with the horizontal shaft bevel gear 31 and is at right angles to the vertical shaft, and is installed in the horizontal shaft housing 25 through a double row ball bearing 35 , and the bearing seat 21 can rotate in the vertical shaft housing 10 . In addition to the above structure, it also includes a lifting device for...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com