Handle lengthening structure for hand-operated tool

A hand tool and handle technology is applied in the field of hand tool handle lengthening structures to achieve the effects of improving work efficiency, quick and convenient adjustment, and easy portability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

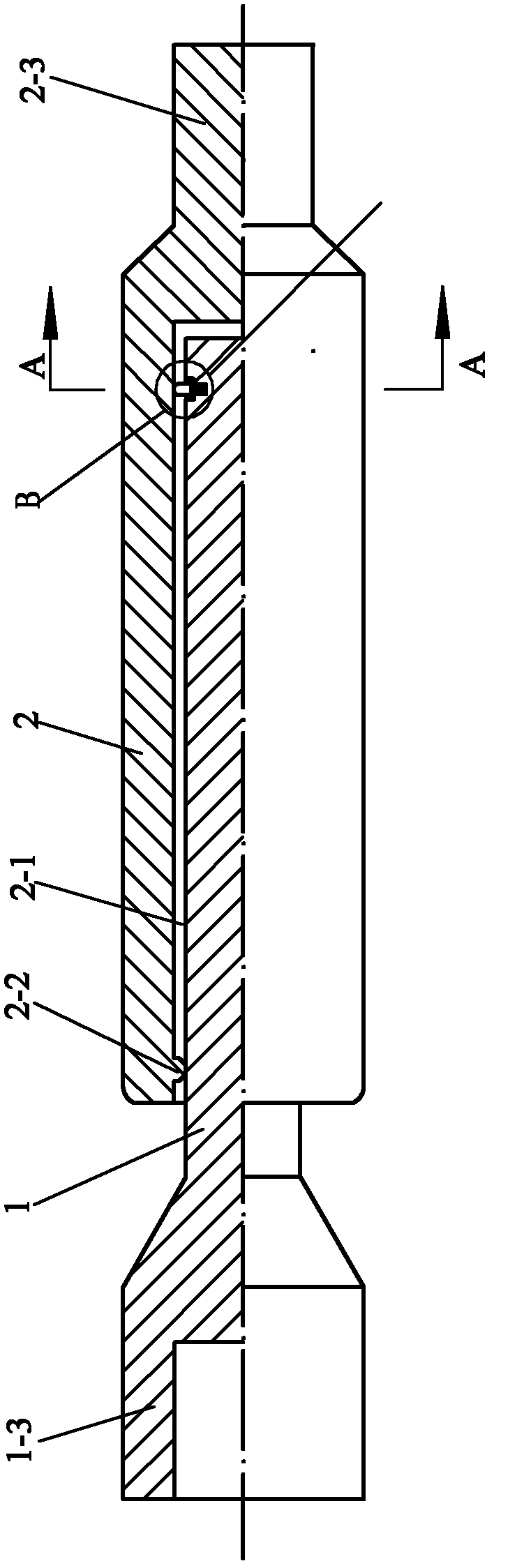

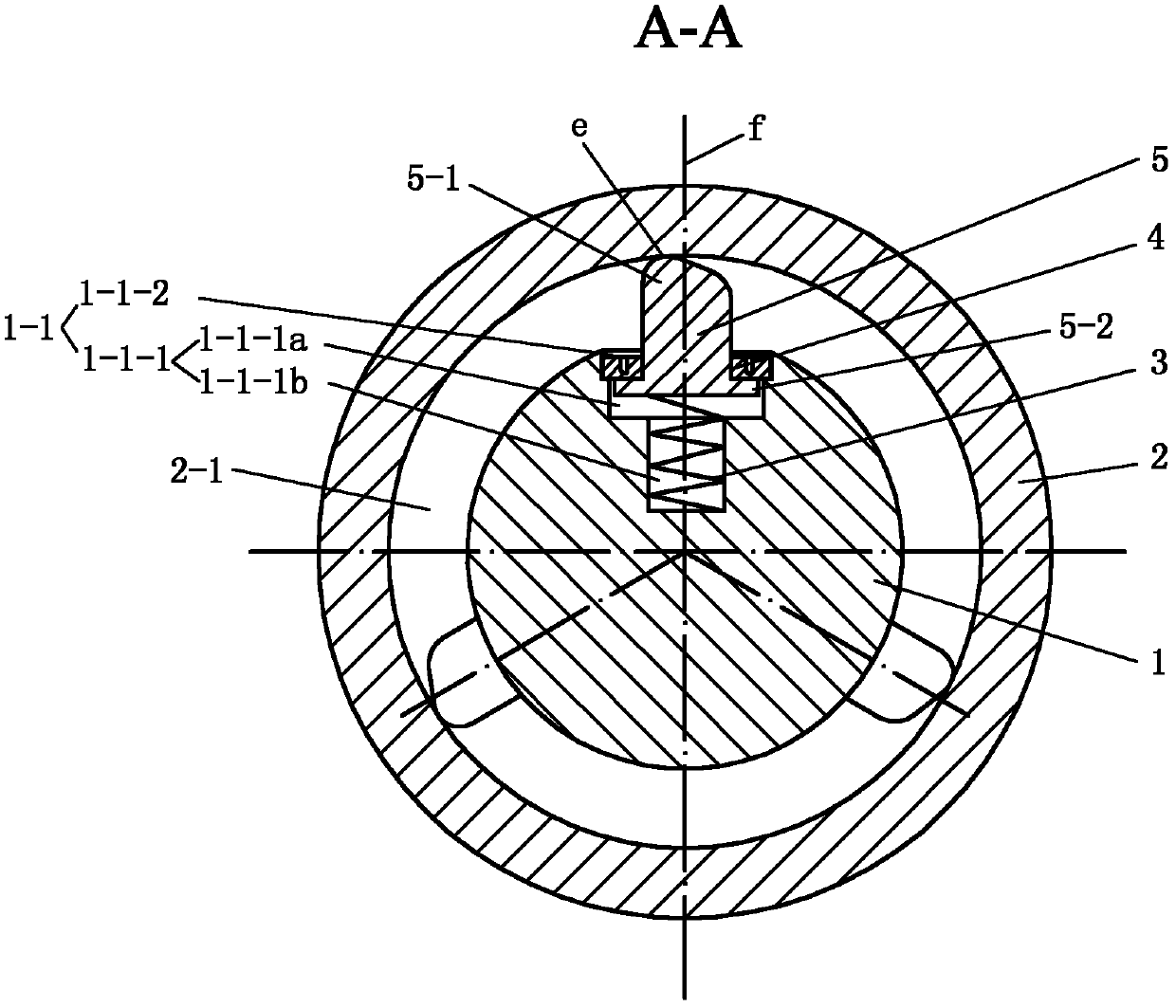

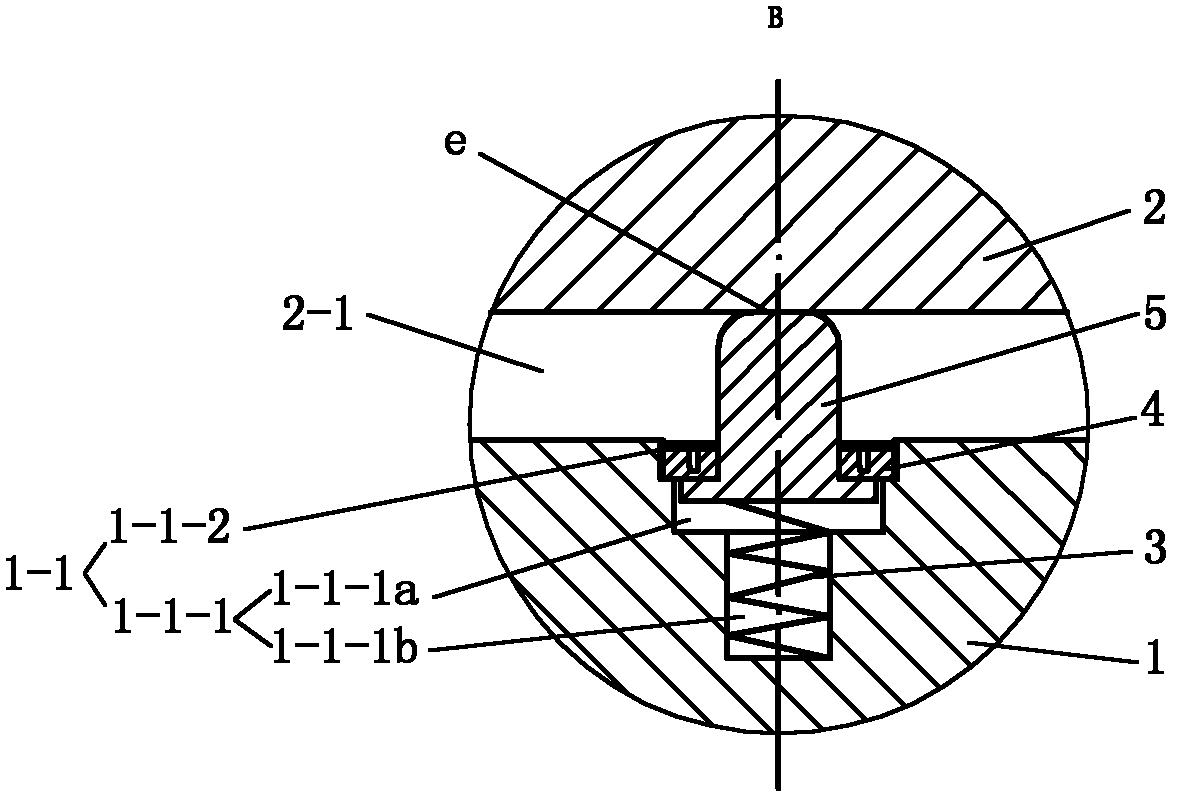

[0012] See Figure 1 to Figure 3 , the illustrated embodiment 1 includes a handle 1 of a hand tool and an extension rod 2 , a spring 3 and a telescoping rod 5 . The handle 1 is rod-shaped, and the extension rod 2 has a central hole 2-1, and the handle 1 is inserted into the central hole 2-1 of the extension rod 2 with a gap between them. On the wall of the central hole 2-1 of the extension rod 2 and near the hole, an arc-shaped convex ring 2-2 is provided to form a fulcrum.

[0013] There are radial blind holes 1-1 distributed at equal angles on the peripheral surface of the handle 1. The number of radial blind holes 1-1 is set according to needs. Generally, three radial blind holes 1-1 are selected for handles with small diameters. The blind hole 1-1 is composed of a stepped hole 1-1-1 on the inside and a threaded reaming hole 1-1-2 on the outside, and the spring 3 is in the small diameter hole 1-1-1 of the stepped hole 1-1-1. In 1b, the telescopic rod 5 is located outside ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com