Material strip deflection correction control device and method

A control device and tape technology, applied in thin material handling, transportation and packaging, winding strips, etc., can solve the problems of tape winding deviation, tape damage, uneven pressure, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

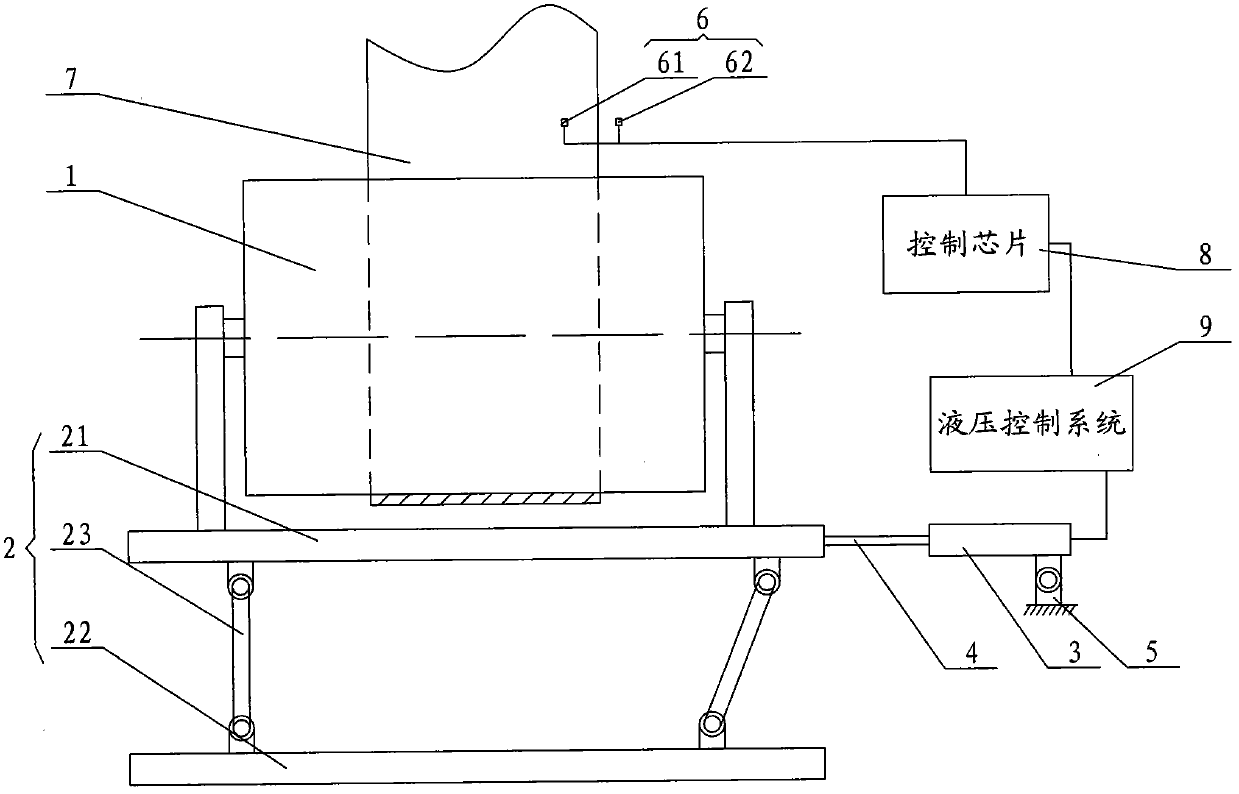

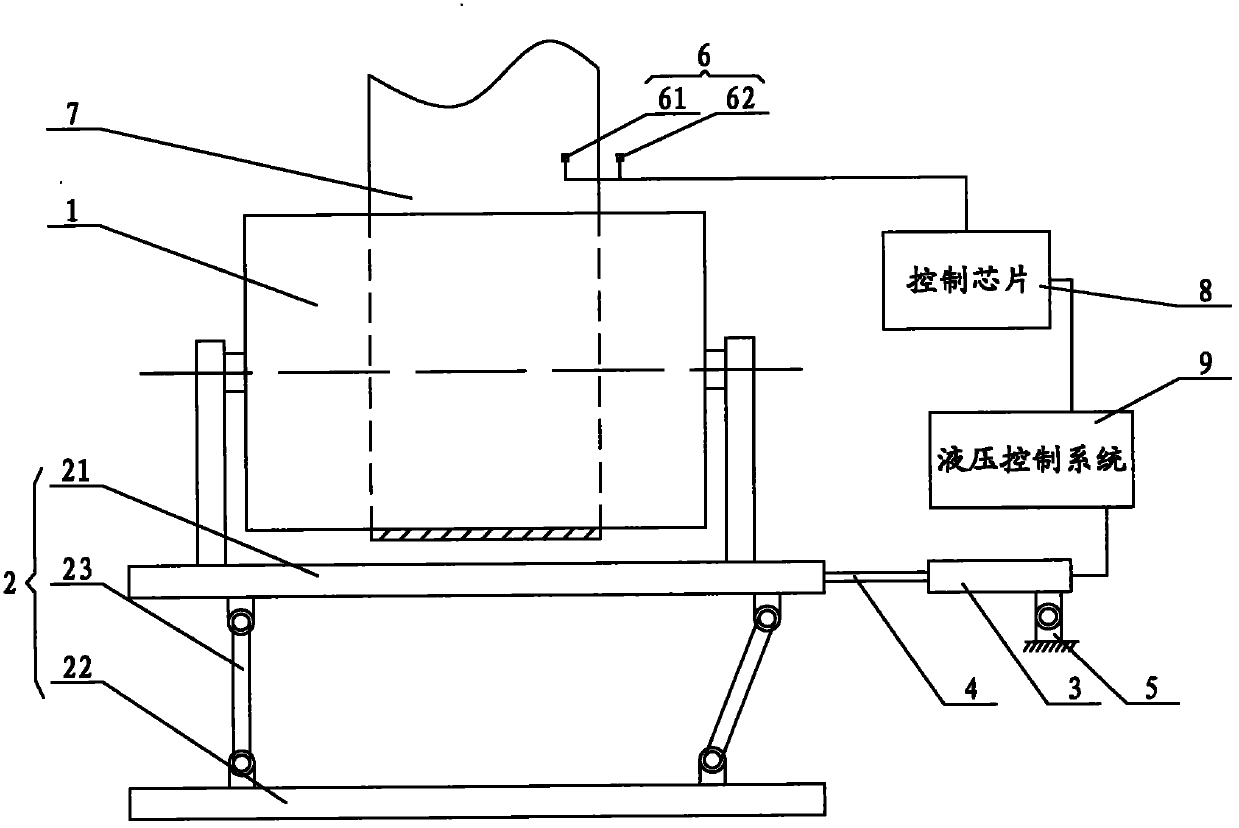

[0017] Such as figure 1 As shown, the material belt deviation correction control device according to the present invention mainly includes a roller 1, a roller inclination control mechanism 2, a driving cylinder 3 and two optical sensors 6 installed on one side of the material belt. 1 is installed on the roller inclination control mechanism 2, one end of the roller inclination control mechanism 2 is connected with the piston rod 4 of the drive cylinder 3, and the two optical sensors 6 are respectively located on the outside of one side of the material belt 7 And on the inner side, two light sensors 6 are electrically connected to the control chip 8 , and the driving cylinder 3 is connected to the hydraulic control system 9 , and the hydraulic control system 9 is electrically connected to the control chip 8 .

[0018] Further, the roller inclination control mechanism 2 includes an upper panel 21 and a lower bottom plate 22, and the upper panel 21 and the lower bottom plate 22 a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com