Double-layer narrow-range webbing loom

A ribbon loom and narrow-width technology, which is applied in looms, textiles, textiles and papermaking, etc., can solve the problems of low production efficiency of ribbon looms, achieve low cost, increase weft insertion rate, and improve production efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

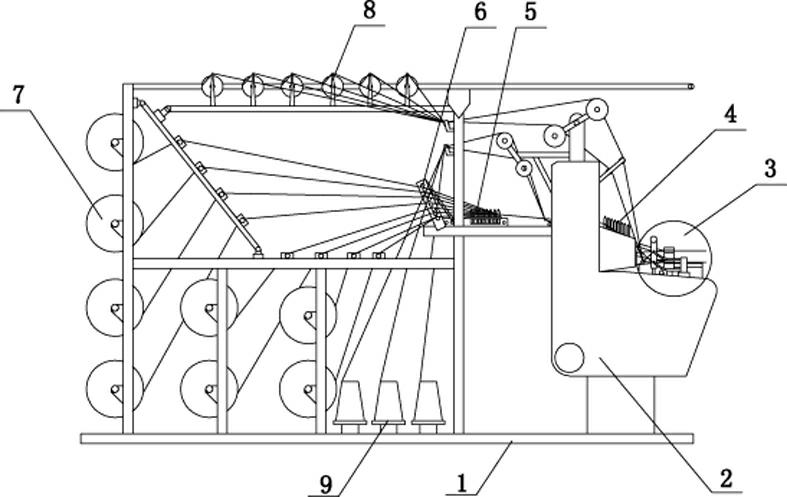

[0023] Example: such as figure 1 As shown, a frame 1 is included, and a power unit 2, a weaving working mechanism and a yarn feeding mechanism are installed on the frame 1. The weaving working mechanism is installed on the front side of the frame 1, and the yarn feeding mechanism is installed on the rear side of the frame 1. The power unit 2 is installed below the weaving mechanism.

[0024] The yarn feeding mechanism further includes a warp yarn delivery device 7 installed on the rear side of the frame 1, an overlock yarn delivery device 9 installed on the lower side of the middle part of the frame 1, a weft yarn delivery device 8 installed on the upper side of the middle part of the frame 1, and an installation The rear reed 6 and warp stopping device 5 in the middle of the frame. Warp delivery device 7 comprises 16 pan heads, and one side is respectively arranged 8. Overlock yarn transfer device 9 has 12 bottom yarn discs, and divides three rows and arranges 4 single rows...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com