Damming method for tailing dam

A tailings dam and tailings sand technology, applied in the field of tailings dam construction, can solve the problems of long consolidation time, low mechanical strength, slow tailings consolidation, etc., and achieve fast drainage and consolidation speed, mature technology, Simple operation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0071] As shown in Figure 1, the method of the present invention specifically comprises the following steps:

[0072] 1. Through the analysis of the whole tailings, the following particle distribution intervals are obtained.

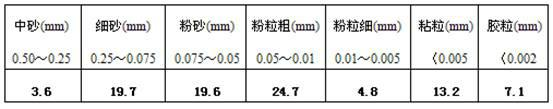

[0073]

[0074] It can be seen from the above particle size range that the main filling tailings come from fine sand and silt, accounting for 39.3% of the total tailings, which can meet the demand for mold bag dam tailings.

[0075] 2. Select the sand taking place

[0076] According to the particle distribution curve of the whole tailings above, the corresponding fine sand and silt distribution locations are concentrated in the range of 40-80m from the top of the beach. Therefore, the sand extraction point for slurry making is selected in this area.

[0077] 3. Dam construction sequence and type design

[0078] According to the topographic conditions of the tailings pond, the dam building site is first selected on the north side, and bags are laid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com