Cyclone sand washing device

A sand washing device and sand washing technology, which is applied in the direction of flushing wellbore, wellbore/well parts, earthwork drilling and production, etc. It can solve the problems of low efficiency of sand washing tools and difficult removal of sand settling, and achieve the effect of improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

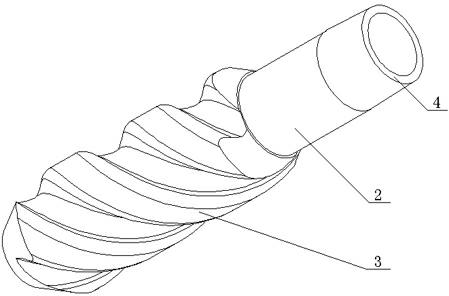

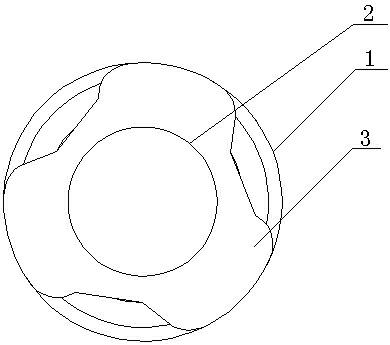

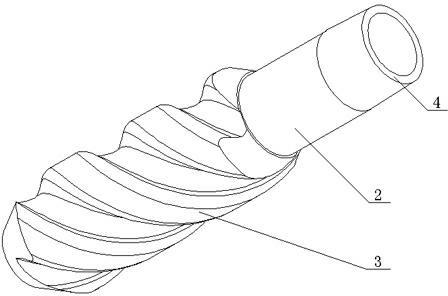

[0016] Such as figure 1 , figure 2 As shown in the structural schematic diagram of this cyclone sand washer, the body 2 of the sand washer is placed at the bottom of the casing 1. There is a spiral groove 3 on the outside of the body 2 of the sand washer, and there is a connector on the upper end of the body 2 of the sand washer 4.

[0017] The sand washer body 2 is placed at the position of the horizontal sand settling section of the inner bottom of the casing 1 or the position of the vertical well section of the casing 1 within 0.5 m from the sand surface.

[0018] The outer diameter of the spiral groove 3 is slightly smaller than the inner diameter of the casing 1, and the sand flusher body 2 is a hollow tubular structure with open ends.

Embodiment 2

[0020] The structure of the spiral groove 3 in this embodiment is a trapezoidal three-thread thread, the spiral lead is between 300 mm and 400 mm, and the crimping of the three-thread spiral is transitioned from the helix surface fillet.

[0021] When performing reverse circulation killing operations, the sand washer body 2 is threadedly connected with a conveying pipe through the upper connector 4, and the sand washer body 2 is conveyed and fixed to the bottom of the casing 1 through the conveying pipe. At this time, the fluid is in 2 Under the pressure of -3MPa, the flow enters the casing 1 at a flow rate of 200-300L / min. When the fluid flows through the body 2 of the sand flusher, a high-speed rotating water flow is formed under the action of the spiral groove 3. The rotating water flow can transfer the casing 1 The sedimented sand at the bottom is washed to the low end opening of the sand washer body 2, and finally discharged from the hollow cavity of the sand washer body 2 th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com