Drying device for architectural ceramic roller table

A technology for drying equipment and building ceramics, applied in progressive dryers, drying gas layout, lighting and heating equipment, etc., can solve the problems of high humidity of exhaust gas, high management costs, limiting the output and scale of production lines, etc. Emission reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described below in conjunction with specific embodiments.

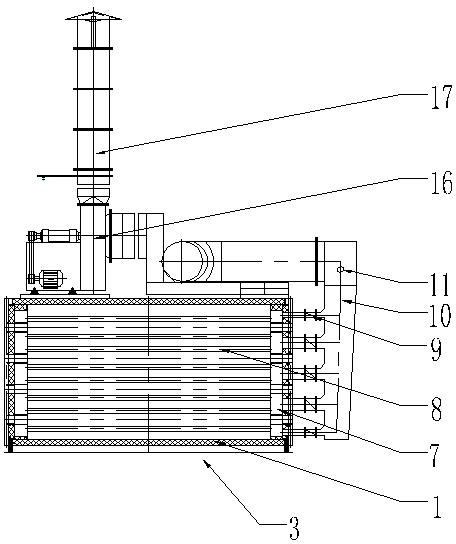

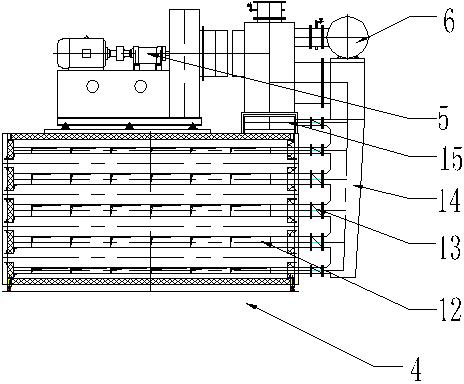

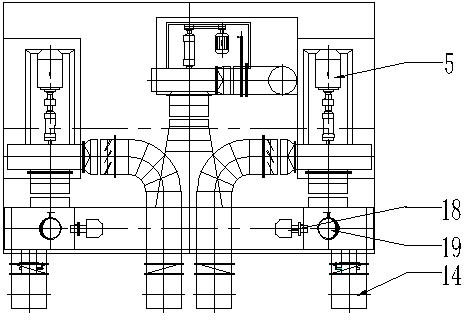

[0019] According to attached figure 1 To attach Figure 7 As shown, the preferred embodiment of the present invention includes a dryer 1, wherein the dryer 1 includes a four-layer roller drying channel 2, and a heating mechanism 3, a moisture discharge Mechanism 4, circulation fan 5, kiln waste heat main pipe 6, wherein, the inlet of the circulation fan 5 is connected with the dehumidification mechanism 4 and the kiln waste heat main pipe 6 respectively; the outlet of the circulation fan 5 is connected with the heating mechanism 3. The heating mechanism 3 of the present invention includes a heating air box assembly 7, a blowing pipe 8, a heating regulating valve 9, a heating connecting pipe 10, and a thermocouple 11, wherein the heating air box assembly 7 is a plurality of left-right symmetrical Installed on and under the rollers of the roller table drying channel 2; the ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap