Optical grade plastic transparent cut display and manufacturing method thereof

A production method and transparent sheet technology, applied in optics, optical components, instruments, etc., can solve the problems of long firing cycle and achieve the effects of light weight, short production cycle and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

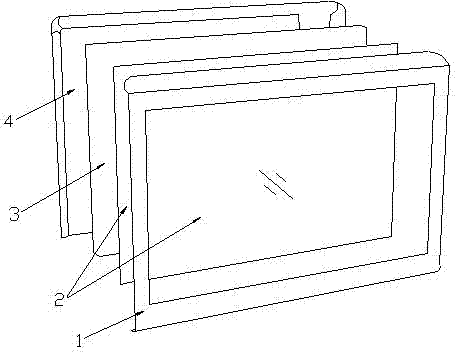

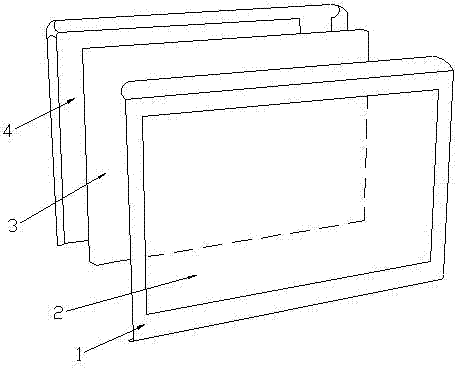

[0011] refer to figure 2 , an optical grade plastic transparent sheet display, comprising a front frame 1, a touch module 2, a display module 3 and a rear cover 4, characterized in that: the touch module 2 is an optical grade plastic transparent sheet, the optical grade The front visual area of the plastic transparent sheet is non-conductively plated with multi-layer coating by NCVM, and the touch area on the back of the optical grade plastic transparent sheet is electroplated with thin film by ITO.

[0012] In this embodiment, the optical-grade plastic transparent sheet and the front frame of the display are integrated, and the front frame 1 and the optical-grade plastic transparent sheet are simultaneously made into one during injection compression molding of PC or PMMA materials; or the optical-grade transparent sheet The transparent plastic sheet is molded by ICM injection molding, and then screen-printed into a sheet and assembled with a front frame with a thin frame t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com