Pneumatic Brake Cylinder

A pneumatic brake and brake cylinder technology, which is applied in the direction of brake cylinder, brake actuator, engine components, etc., can solve the problem of high installation cost, and achieve the effect of saving installation cost, reducing installation cost and simplifying installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

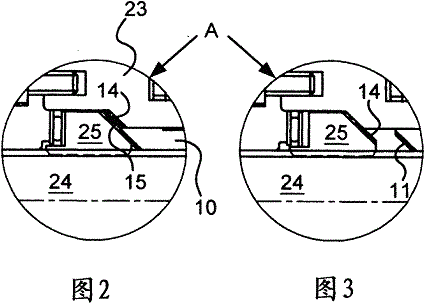

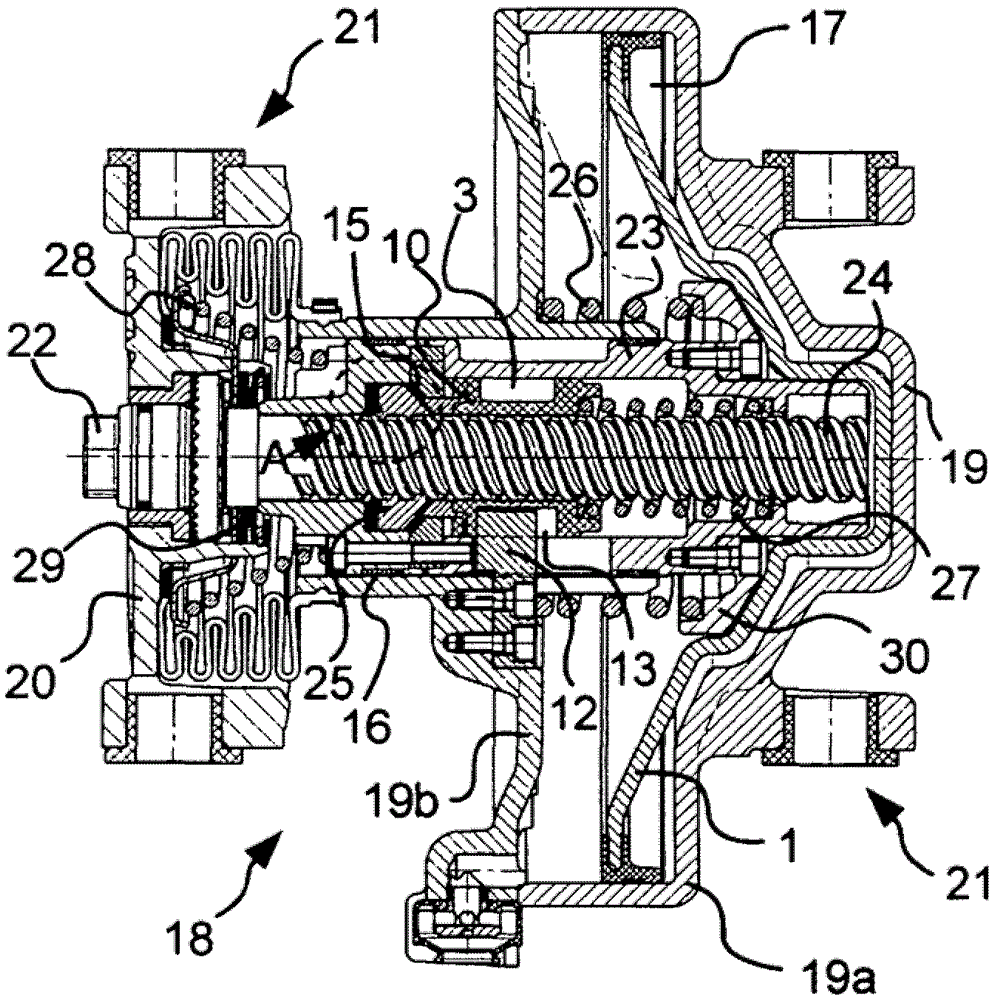

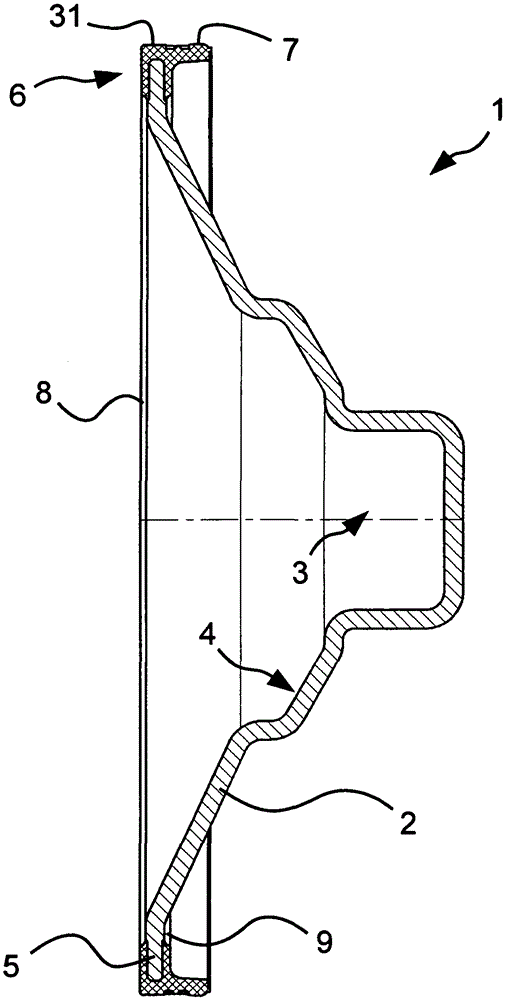

[0020] Figure 4 The new piston 1 shown is designed as a deep-drawn part 2 and is made of sheet steel. In the middle of the piston 1 there is a piston tube receptacle 3, by means of which the piston 1 is placed on the figure 1 On the piston tube 23 shown. There is no direct connection between the piston tube receptacle 3 and the piston tube 23 . Instead, the piston 1 acts on the piston tube 23 via the annular, conically formed contact surface 4 of the piston 1 , and the piston 1 is also centered via the contact surface as soon as the piston 1 is pressurized. In another embodiment not shown here, the piston can also be accommodated by the housing of the brake cylinder and guided through it.

[0021] The sealing ring 6 is vulcanized and bonded to the piston rim 5 . The sealing ring is L-shaped, one of its legs enclosing the piston lip 5 in a groove-like manner. The groove formed in the sides is delimited by a lower lip 8 and an upper lip 9 . The lower lip 8 and the upper l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com