Foldable moving bedstead

A foldable, bed frame technology, applied in the field of bed frames, can solve the problems of large steel wires, less stacking, waste of steel, etc., and achieve the effects of reducing material costs, transportation costs, and weight.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

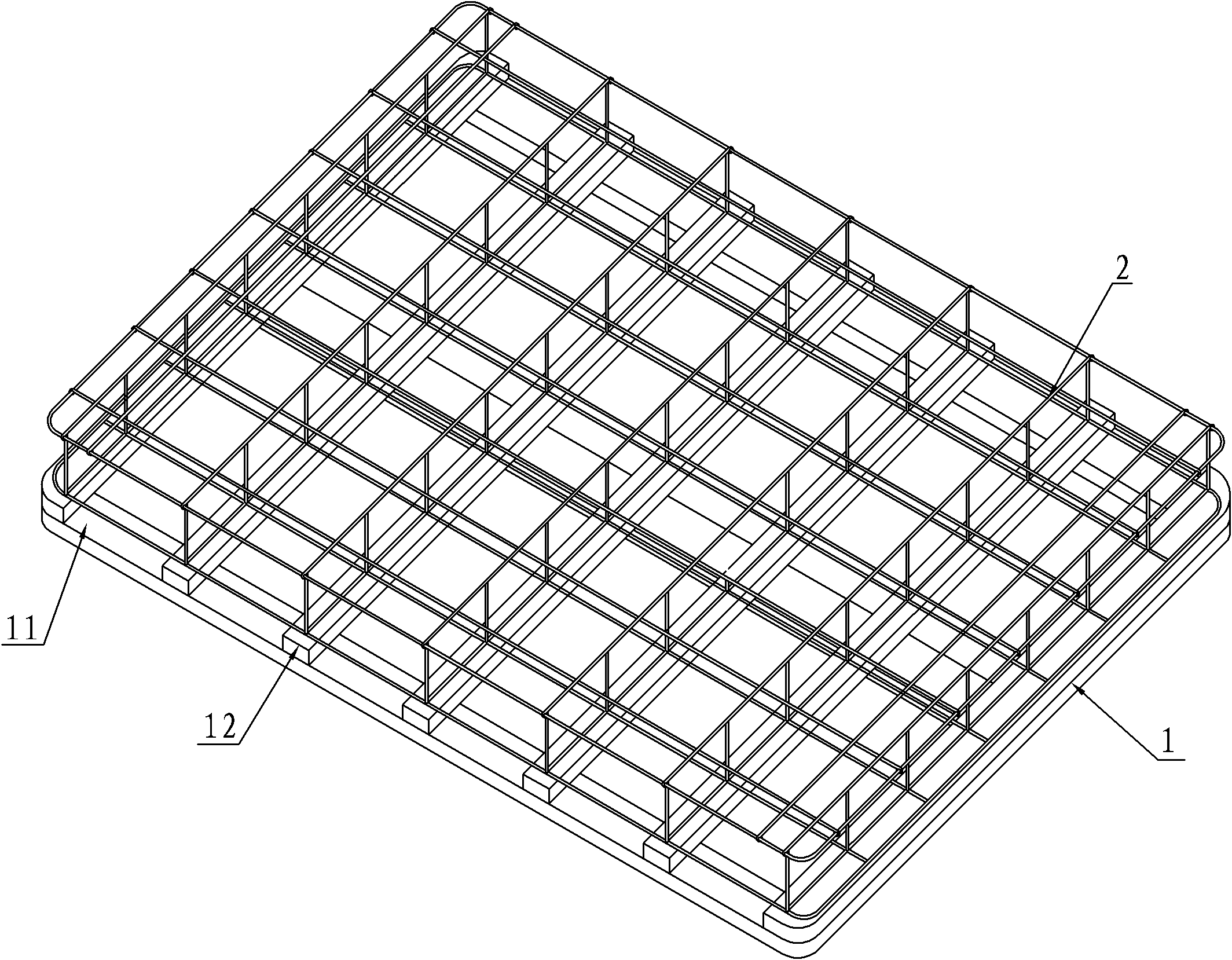

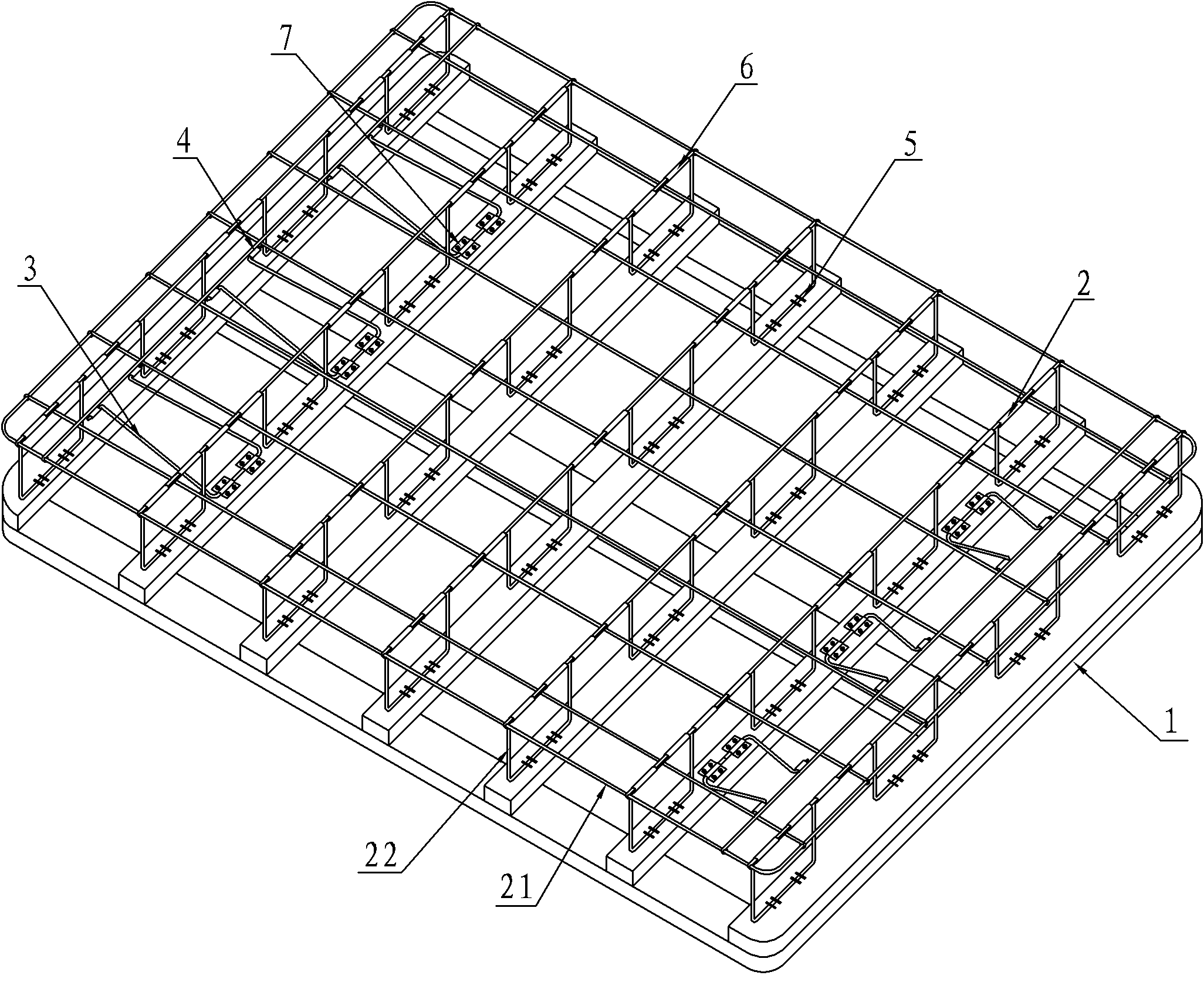

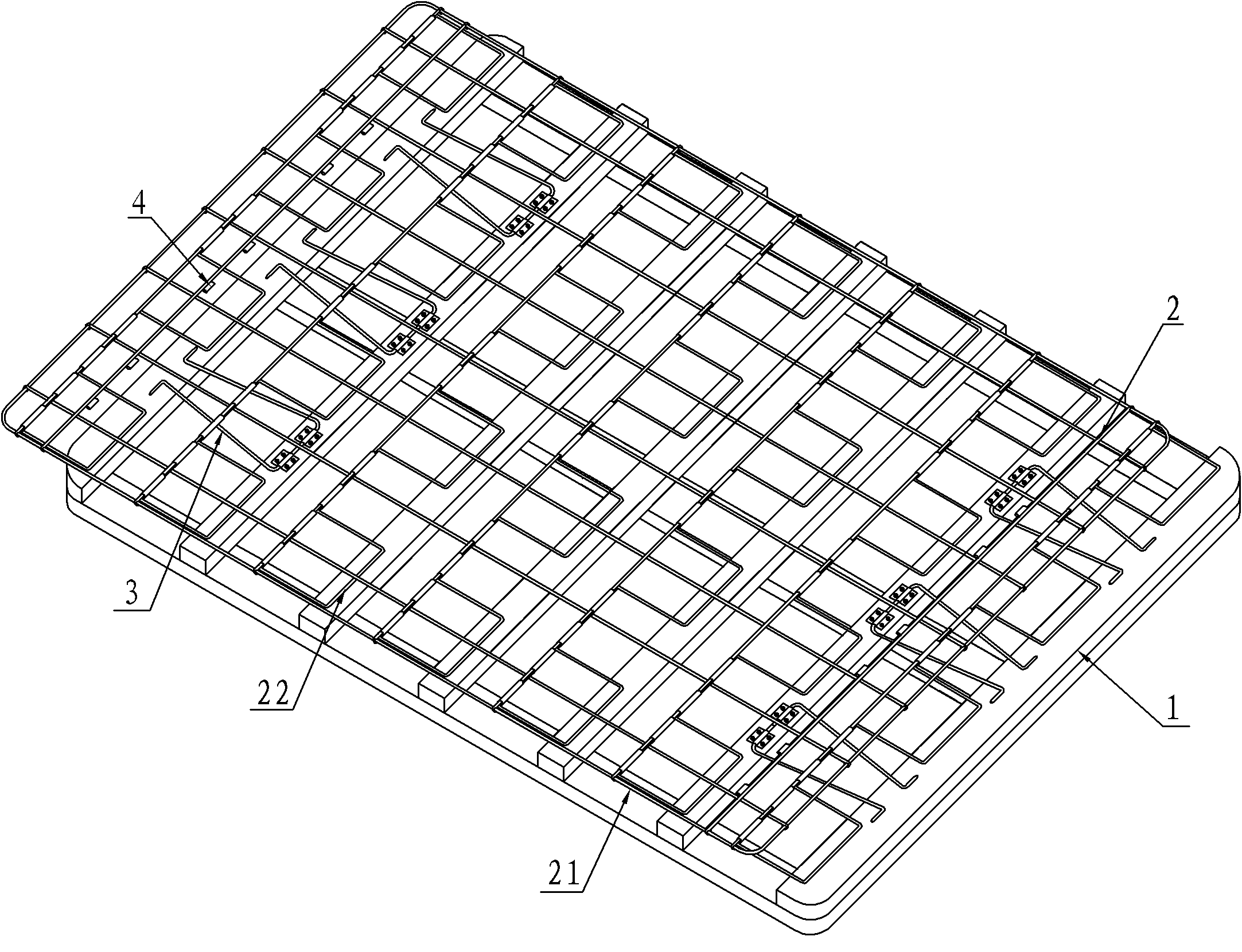

[0024] Embodiment 1: a kind of collapsible movable bed frame, such as figure 2 , image 3 As shown, it consists of a wooden frame 1, a steel mesh frame 2, a support rod 3, a positioning sleeve 4, a row of nails 5, a chuck 6 and a repin seat 7, and the wooden frame 1 is as Figure 4 As shown, it consists of a rectangular bed frame 11 and five transverse stays 12, and the five transverse stays 12 are fixed on the rectangular bed frame 11 at equal intervals along the length direction of the rectangular bed frame 11; and the pressure-bearing row frame 22, the steel mesh frame 21 is as Figure 5 As shown, it is made up of steel wire frame 211, transverse steel wire 212 and longitudinal steel wire 213, and transverse steel wire 212 is distributed along the length direction of steel wire frame 211 at equal intervals, and longitudinal steel wire 213 is distributed at equal intervals along the width direction of steel wire frame 211; The row frame 22 is formed by bending a circular ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap