Ladder-shaped bamboo original state recombined material and manufacturing method thereof

A recombined wood and trapezoidal technology, applied in the field of materials, can solve the problems of unfavorable large-scale production, the utilization rate of whole bamboo is less than 25%, and the original state of bamboo is lost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

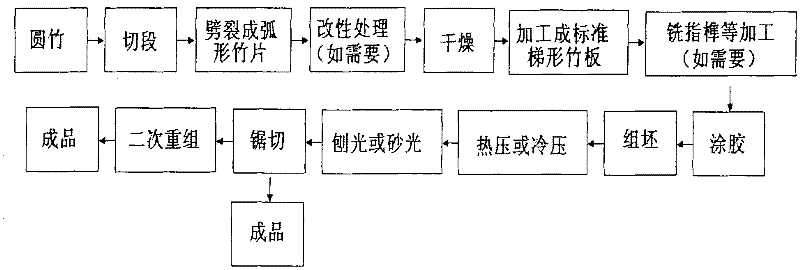

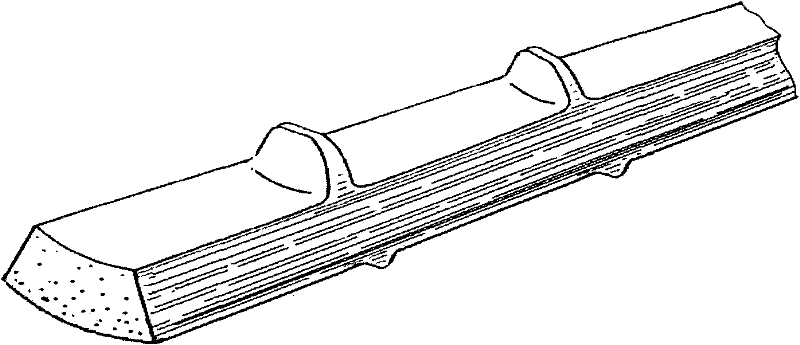

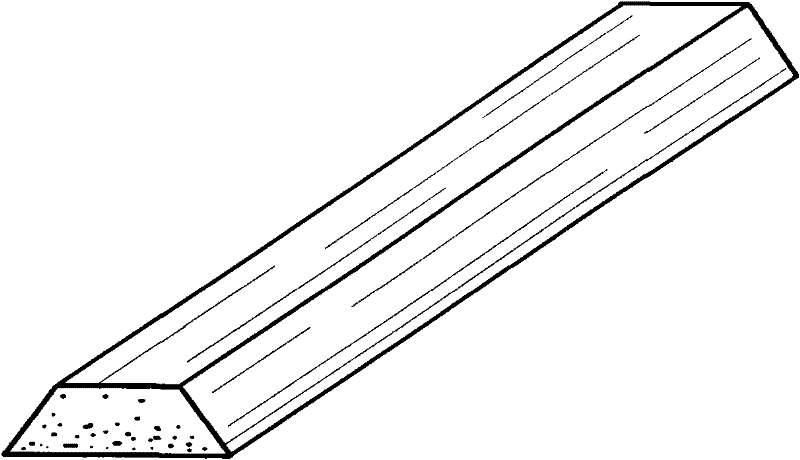

[0060] figure 1 For the manufacturing process flow of the trapezoidal bamboo original state recombined material of the present invention, the moso bamboo with a diameter at breast height of 80 to 120 mm is selected as the basic material, and the round bamboo is split into curved bamboo blanks of certain specifications according to the difference in diameter at breast height of the bamboo, such as figure 2 As shown, after milling into standard trapezoidal cross-section bamboo boards with consistent specifications (see image 3 ), one end or double end milling finger tenon, according to the set finger joint bamboo board as the set length. Then arrange and group the blanks to superimpose and glue them into plates, or reorganize them twice to form square materials. Specific steps are as follows:

[0061] (1) Cut the moso bamboo into standard sections with a length of 500-2000 mm according to the diameter, taper, wall thickness and straightness of the bamboo. The bamboo splitti...

Embodiment 2

[0088] refer to Figure 1 ~ Figure 3 , Figure 6 As shown, large-scale dragon bamboo with a diameter at breast height of 100-200 mm is selected as the basic material. According to the different diameters of the bamboo materials, the round bamboo is split into arc-shaped bamboo blanks of certain specifications, and then processed into standard trapezoidal bamboo boards with the same specifications after milling. One end or Double short milling fingers. Then arrange and group the blanks to superimpose and glue them into materials of various geometric shapes, or reorganize them twice to form larger-sized square materials. Specific steps are as follows:

[0089] (1) According to the diameter, taper, wall thickness and straightness of the bamboo, saw the dragon bamboo and cut it into standard sections with a length of 100-3000mm. The bamboo splitting machine is used to split the round bamboo into arc-shaped bamboo blanks.

[0090] Specifications: Length: 1000~3000mm

[0091] W...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

| Dbh | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com