Manufacturing method of rubber component for tire and manufacturing device used therein

A technology of rubber parts, manufacturing methods, applied in the field of manufacturing devices, capable of solving problems such as shrinkage, dimensional changes, and cutting of rubber bands

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0045] Next, one embodiment of the present invention will be described based on the drawings.

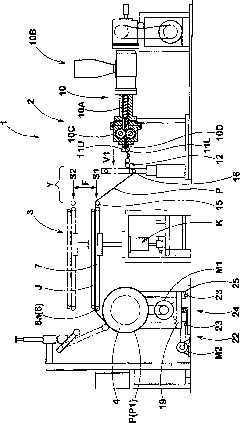

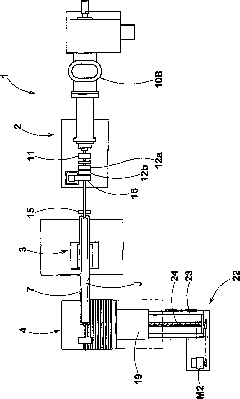

[0046] exist figure 1 and figure 2 Among them, the manufacturing device 1 of rubber parts for tires is a manufacturing device in which a long strip-shaped rubber belt P made of unvulcanized rubber is wound and pasted in a spiral shape on a cylindrical molding machine 4 to form a A rubber part P1 for a tire constituted by the wound body of the rubber tape P. In this embodiment, the manufacturing apparatus 1 of the rubber member for tires constitutes a part of a production line for manufacturing tires T. As shown in FIG.

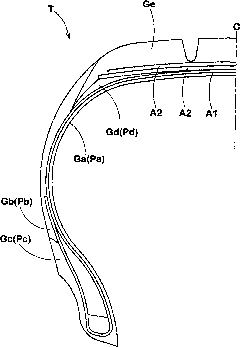

[0047] like image 3 In this way, in addition to the cord layers such as the carcass A1 and the breaker A2, the tire T is mainly composed of inner liner Ga, sidewall Gb, chafer Gc, breaker Gd, and tread rubber Ge. A rubber part G constitutes. Furthermore, the rubber manufacturing apparatus 1 sequentially forms the inner liner Ga, sidewall Gb, chafer Gc, and c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com