Liquid ejecting apparatus and control method thereof

A jetting device and liquid jetting head technology, applied in printing devices, printing, etc., can solve problems such as difficulty in suppressing ink consumption, poor jetting, and reduced image quality of recorded images

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 2 Embodiment

[0046] Next, a second embodiment will be described. In the second embodiment, configurations different from those in the first embodiment will be described, and unless differences are mentioned, the printer configuration and its control method are the same.

[0047] Figure 5 It is a flowchart explaining the flow of flushing in the second embodiment.

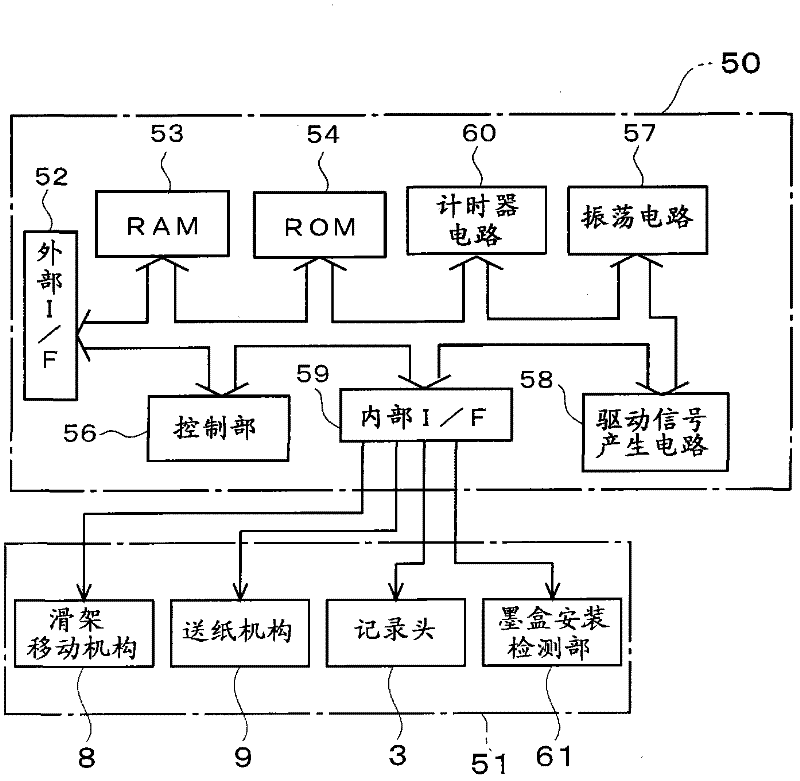

[0048] In the printer 1 of the present invention, a configuration may be employed in which the resonance pulse FLP1 of the second embodiment is set to be ejected from the nozzle opening 35 when the piezoelectric vibrator 30 is driven, compared with the recording drive pulse. The ejection amount of the ink is large and the flying speed of the ink is fast. If the normal printing mode is switched to the flushing mode, the resonance pulse FLP1 is applied to the piezoelectric vibrating element 30 to perform the first flushing process, and then the recording drive pulse is applied. The piezoelectric vibrator 30 is used to execute th...

no. 3 Embodiment

[0053] Next, a third embodiment will be described. The third embodiment will describe the different configurations from the first embodiment, and the printer configuration and its control method are the same unless there is any difference.

[0054] Figure 6 It is a table showing the driving pulses used in the flushing of the third embodiment.

[0055] In addition, the printer 1 according to the third embodiment may be configured such that the drive signal COM generated by the drive signal generation circuit 58 includes setting the ejection amount and flying speed of the ink ejected from the nozzle opening 35 when the piezoelectric vibrator 30 is driven. The intermediate pulse FLP2 (for example, Th=3Tc / 4, Vd=0.8Vd1) having a value between the driving pulse for recording and the resonance pulse FLP1 is applied to the pressure after the first flushing process and before the second flushing process. The electro vibrator 30 is used to perform the third rinse process. That is, t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com