Waveform heat transfer element of heat exchanger

A technology of heat transfer elements and heat exchangers, which is applied in the field of wave heat transfer elements of heat exchangers, can solve the problems of low heat transfer efficiency, high cost, and huge outsourcing workload of heat exchangers, etc., and achieve high heat exchange efficiency , low running resistance, conducive to the effect of online cleaning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

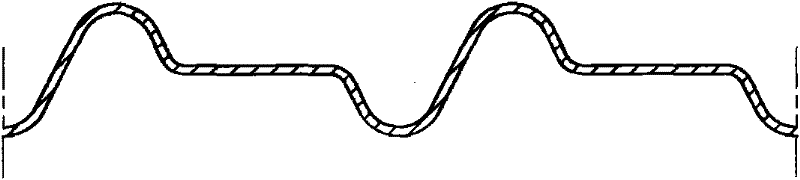

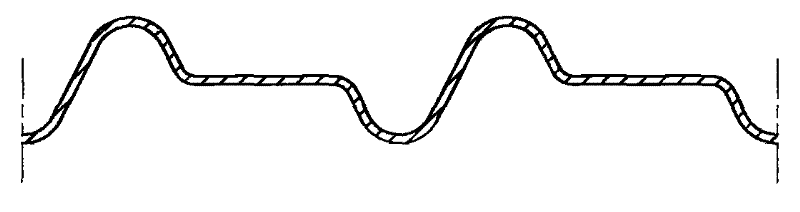

[0008] like figure 1 As shown, a corrugated heat transfer element of a heat exchanger of the present invention is formed by pressing a steel plate coated with high-quality heat-resistant enamel; a flat surface is formed between the pressed "S"-shaped waves, and the flat surface is located in the section " The middle position between the upper and lower vertices of the S-shaped waveform, the pitch between the adjacent "S"-shaped waveform vertices is 30-38mm, and the distance between the upper and lower vertices of the "S"-shaped waveform is 8-12mm.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com