Filters and washing machines with circulating water filtration systems

A filter and water filtration technology, which is applied in the field of washing machines, can solve the problems of unstable water quality, short service life, manual cleaning of water storage tanks and filter screens, etc., to solve the problem of lint pollution, simplify internal pipeline settings, and prevent The effect of dirty water backflow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

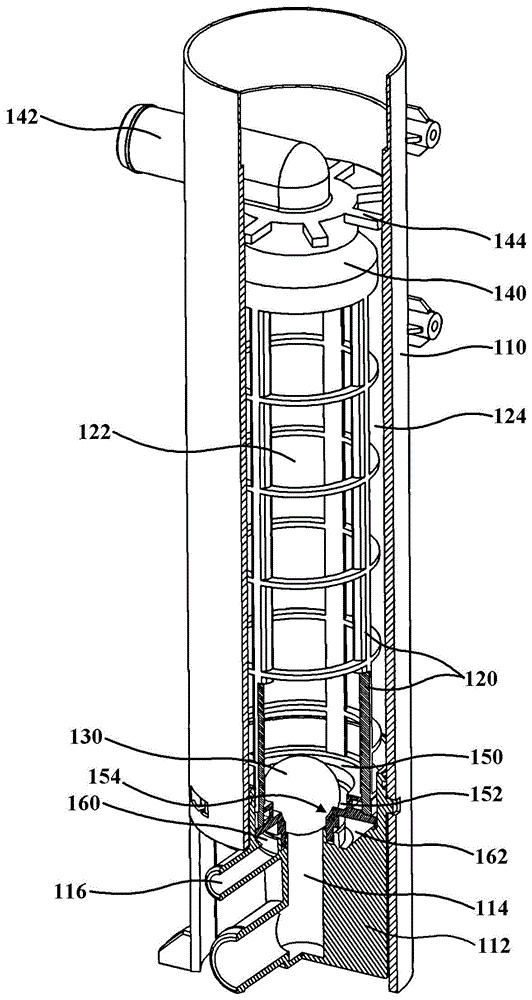

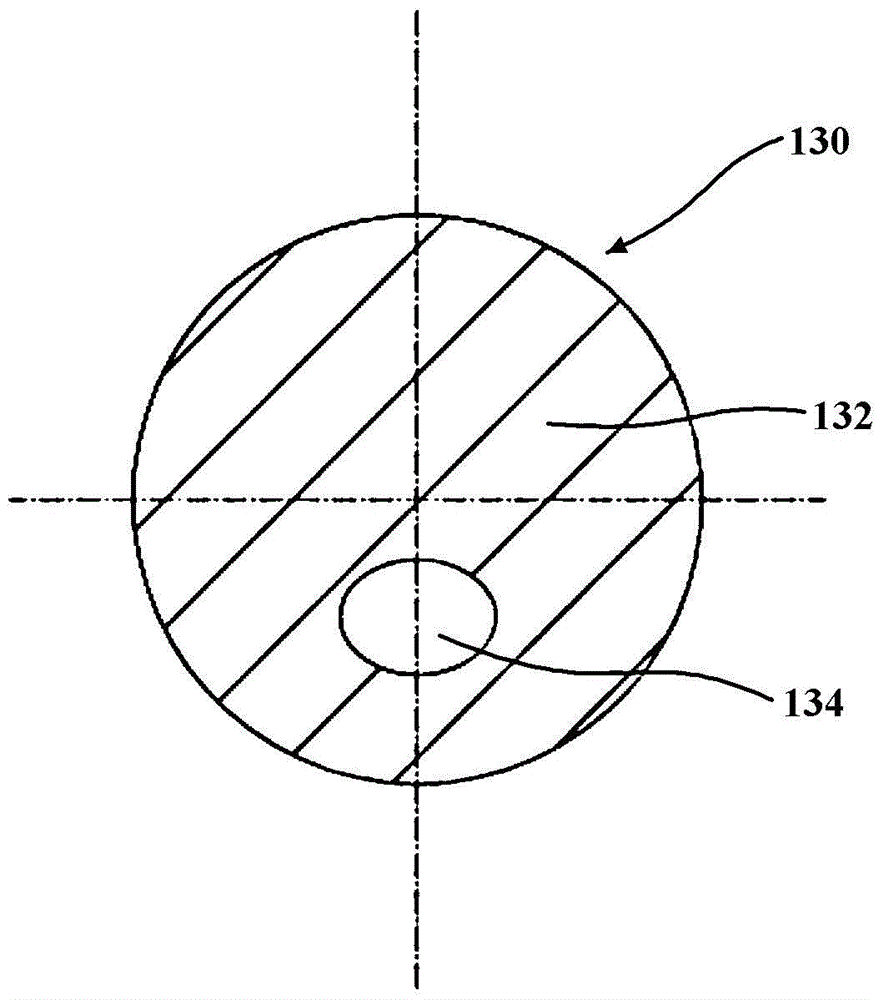

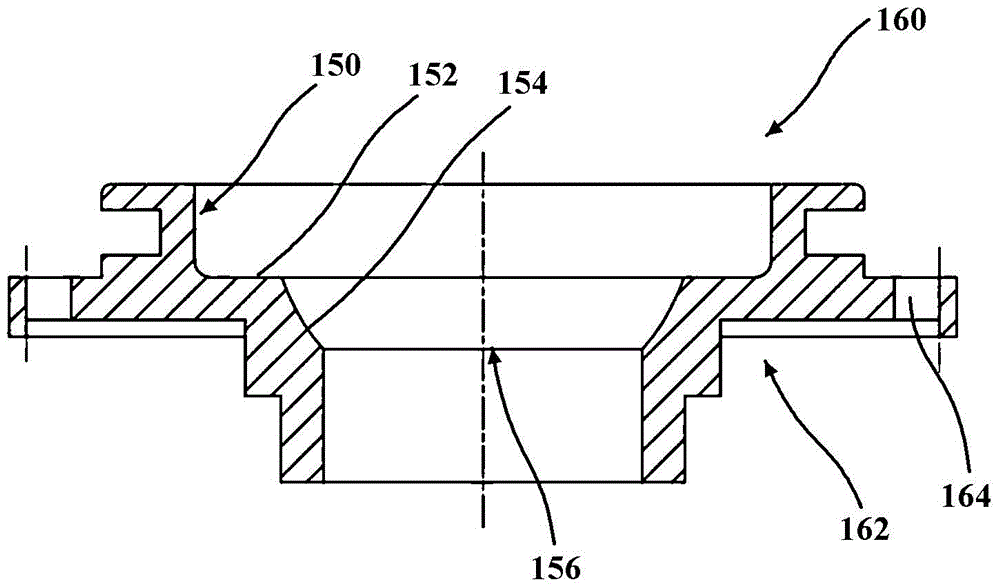

[0040] figure 1 is a schematic structural diagram of a filter according to an embodiment of the present invention. Such as figure 1 As shown, the filter may include a housing 110 and a filter screen 120 disposed in the housing 110 . The filter screen 120 separates the inner chamber of the housing 110 into a water inlet chamber 122 and a water filter chamber 124 . The water entering the water inlet cavity 122 is filtered by the filter screen 120 and then enters the water filter cavity 124 . A fluid non-return member 130 is provided on the water inlet of the water inlet chamber 122 for opening or closing the water inlet.

[0041] In some embodiments of the present invention, the water inlet of the water inlet chamber 122 may be located at the bottom thereof. In a further embodiment, the fluid non-return member 130 can open or close the water inlet according to the following conditions. Specifically, when the water to be filtered flows to the bottom of the fluid non-return m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com