Self-supporting wide gap heat exchange element

A heat exchange element and wide-gap technology, applied in the field of self-supporting wide-gap heat exchange elements, can solve the problems of difficult to control positioning accuracy, difficult to grasp welding deformation, and difficult for flue gas circulation, etc., to reduce maintenance costs, design economical, The effect of convenient online cleaning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] Embodiments of the present invention are further described below in conjunction with accompanying drawings:

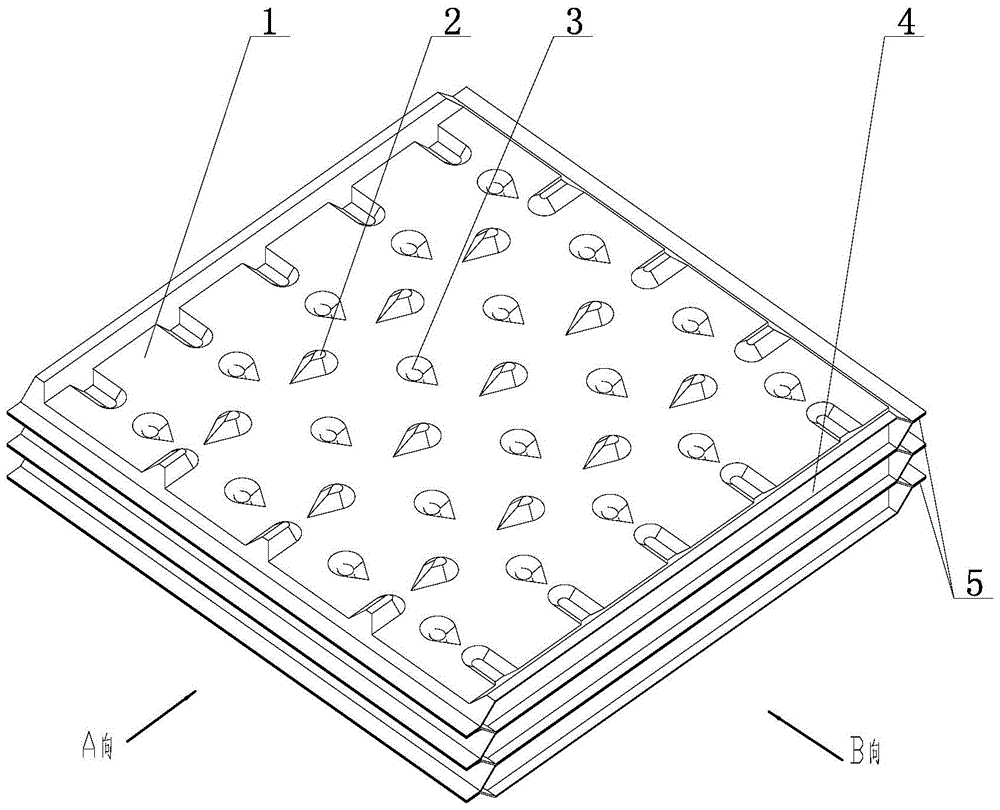

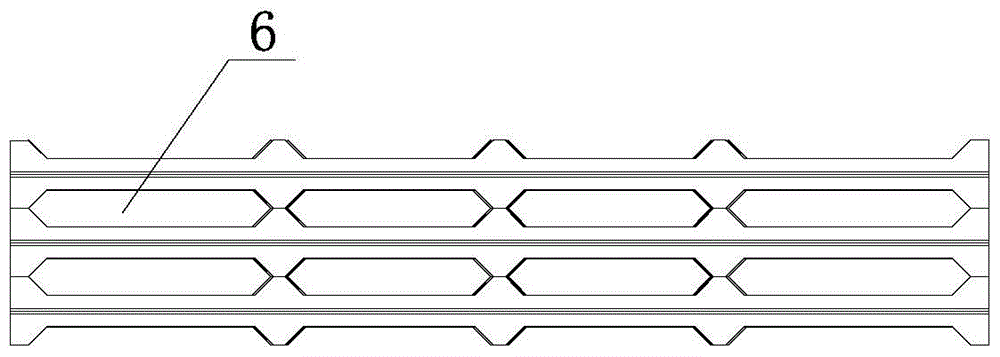

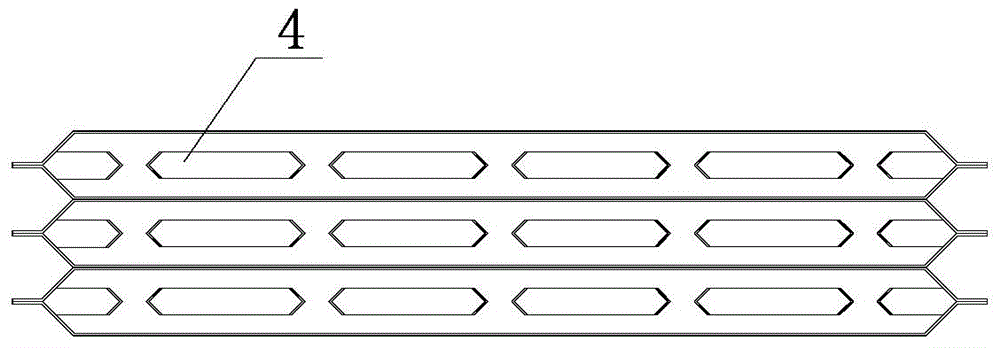

[0029] Such as Figure 1~3 As shown, the self-supporting wide-gap heat exchange element of the present invention includes several plate pairs 5 stacked in layers, and each plate pair 5 includes two upper and lower plates 1 oppositely arranged, and the upper surface of the plates 1 is along the Several rows of convex corrugations 2 and concave corrugations 3 are distributed in the direction of the same axis. Convex corrugations 2 and concave corrugations 3 are obtained by pressing plates upward and downward respectively. Convex corrugations 2 and concave corrugations are distributed at intervals. The concave corrugations and convex corrugations of the middle and upper plates correspond to the positions of the convex corrugations and concave corrugations of the lower plate respectively. One set of opposite sides of plate 1 is folded upwards and transitions to a pl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com