NA (Numerical Aperture) connector type sight mirror

A sight glass and interface technology, applied in the field of NA interface type sight glass, can solve the problems of visual dead angle and high cost of glass sintering process, and achieve the effect of good hygienic performance, broad economic benefits and application prospects, and convenient online cleaning.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention is further illustrated below by means of examples, but the present invention is not limited to the scope of the examples.

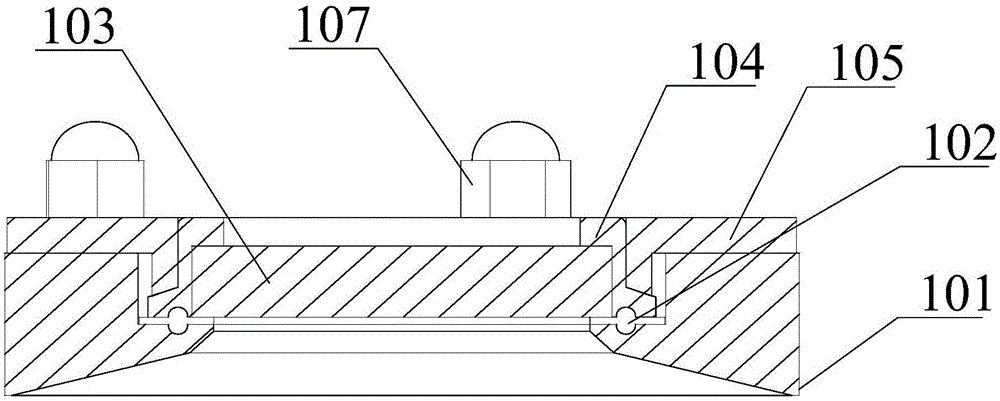

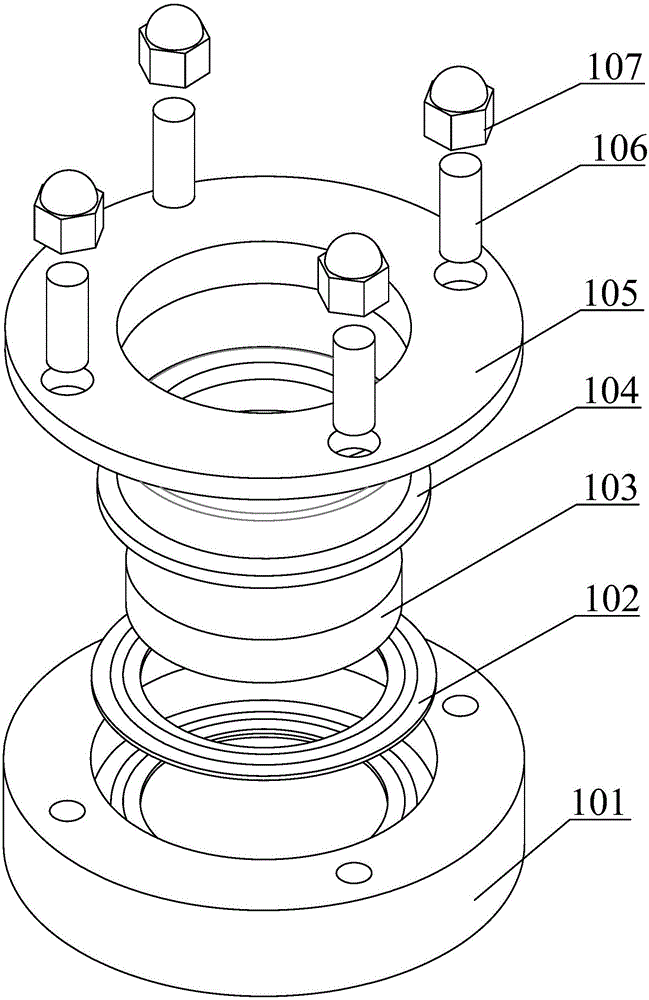

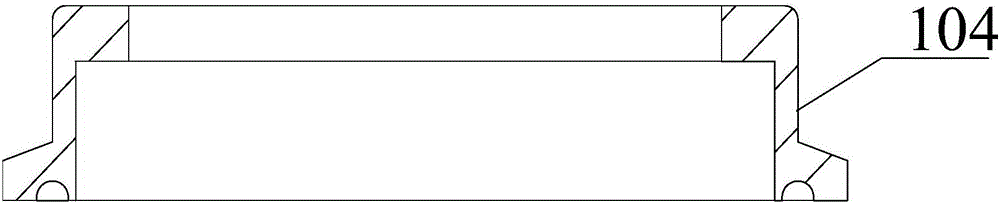

[0022] Such as Figure 1~3 As shown, this embodiment provides a NA interface type sight glass, which includes a sight glass base 101, a sealing gasket 102, a sight glass 103, a glass gland 104, a mirror gland 105, a stud 106 and a cap nut 107; the mirror glass 103 is located at the center of the mirror base 101, and a sealing gasket 102 is arranged between the mirror glass 103 and the mirror base 101; the glass gland 104 is a ring piece , the glass gland 104 includes a crimping section with an upper edge protruding inward and a sealing section with a lower edge protruding outward, and the glass gland 104 is covered on the mirror glass 103 through the crimping section , the sealing section fits with the sealing gasket 102; the mirror gland 105 is a ring, and the mirror gland 105 includes a transition section protruding downwar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com