Low-voltage application test method for fault current limiter valve set

A technology of fault current and limiter, applied in the field of power system, can solve the problem that the capacitor bank does not have and cannot obtain the forward conduction voltage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

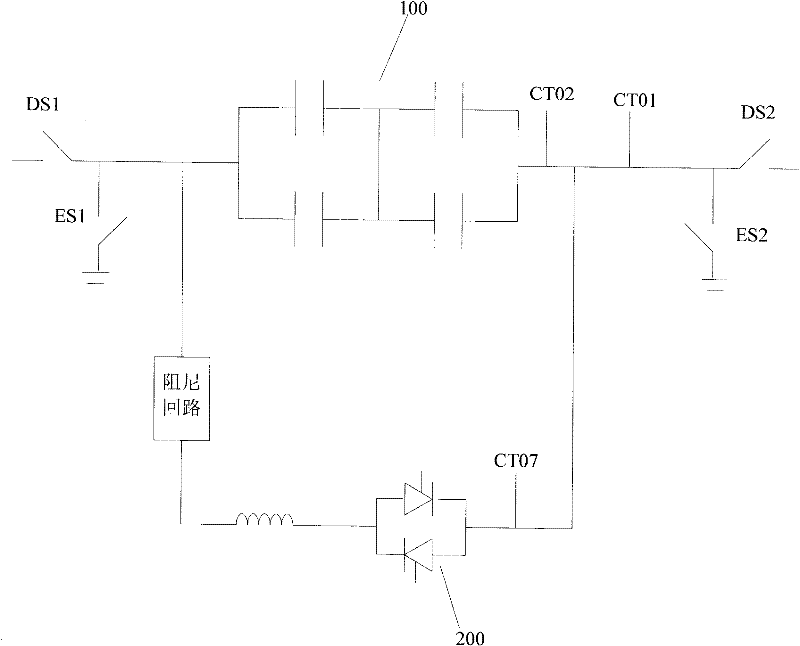

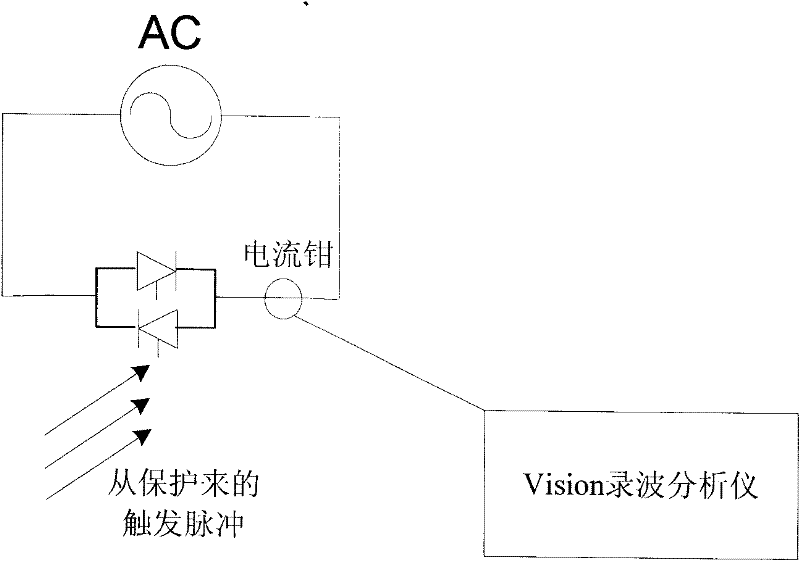

[0021] In order to better understand the technical content of the present invention, specific embodiments are given and described as follows in conjunction with the accompanying drawings.

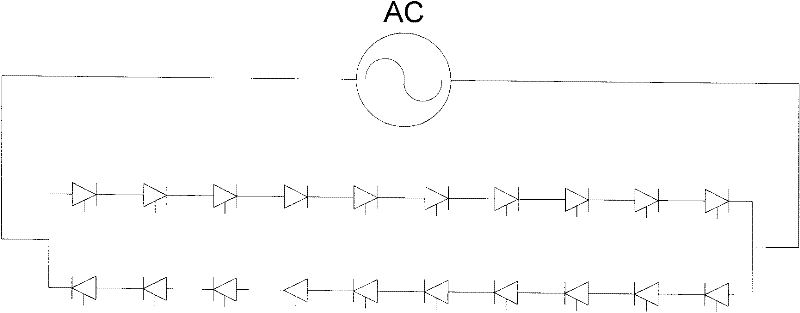

[0022] This test method involves the technology of how to test whether the thyristor valve element can be correctly triggered to conduct in the power system. Under normal operating conditions, the conduction of the valve element requires a certain forward pressure drop, that is, there must be a certain pressure difference on both sides of the valve group, but in the debugging stage, there is no current on the line, and no pressure can be formed on both sides of the valve group. Poor, so even under the conditions of protection triggering and laser energy acquisition, the valve element cannot be properly conducted. Therefore, it is necessary to check that the connection between the control protection, VBE, TE, TM and valve components is correct, and that the valve components can be correctly ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com