Five-freedom-degree precise position fixing device for adjustment of lens sets

A technology for precise positioning and fixing devices, applied in installation, optics, instruments, etc., can solve problems such as large accidental errors and poor optical axis consistency, and achieve the effects of low manufacturing cost, avoidance of accidental errors, and high positioning optical axis consistency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

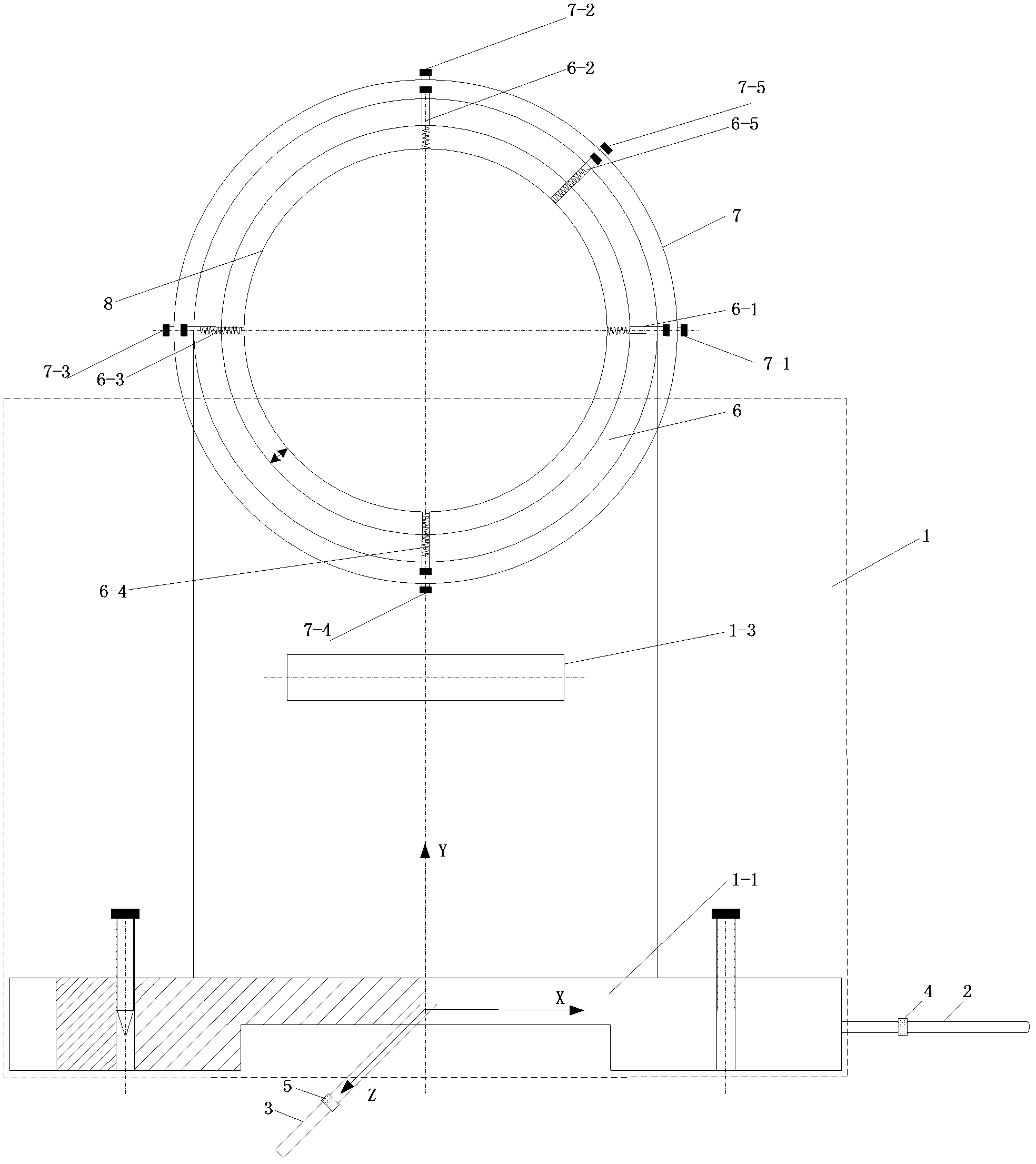

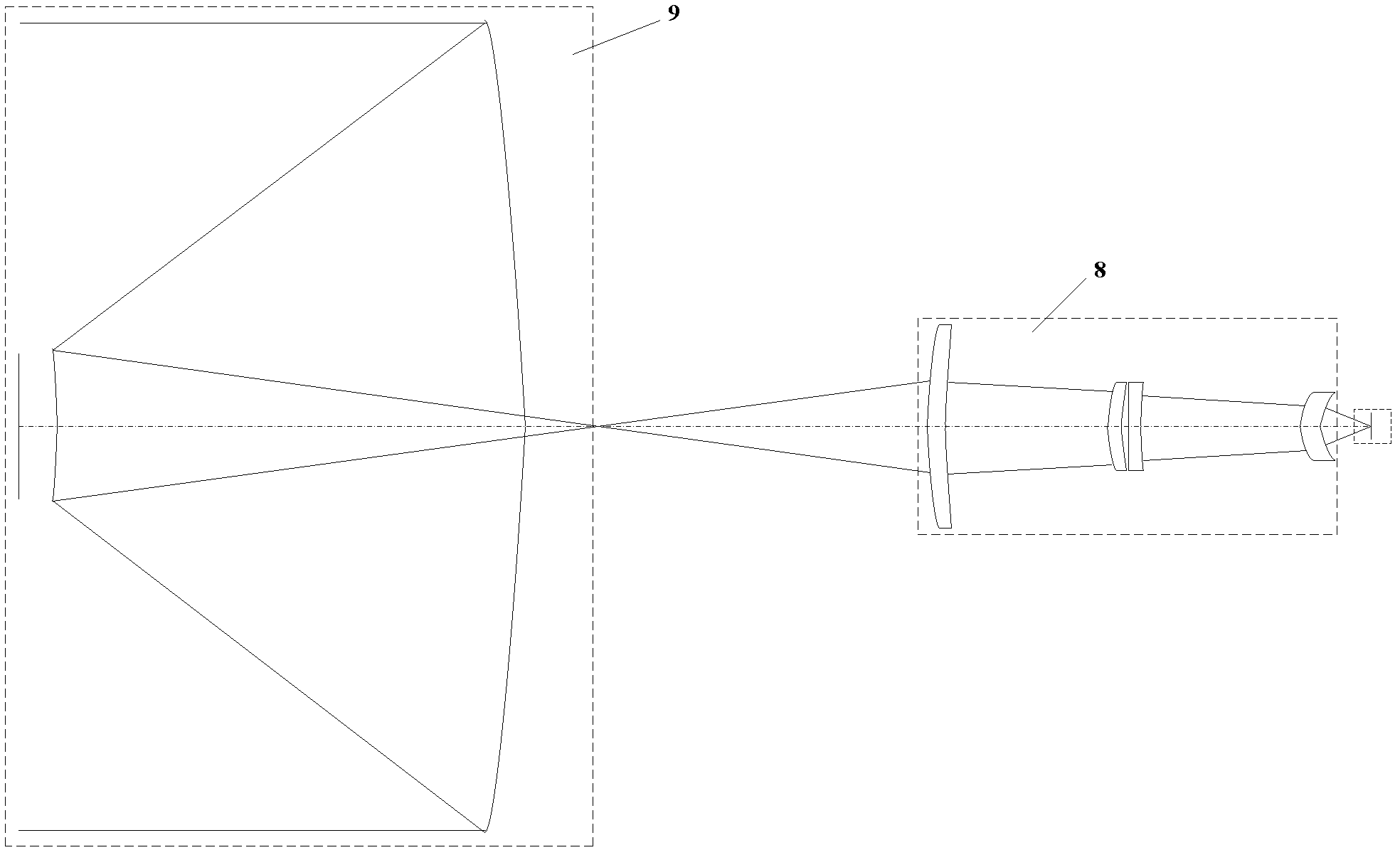

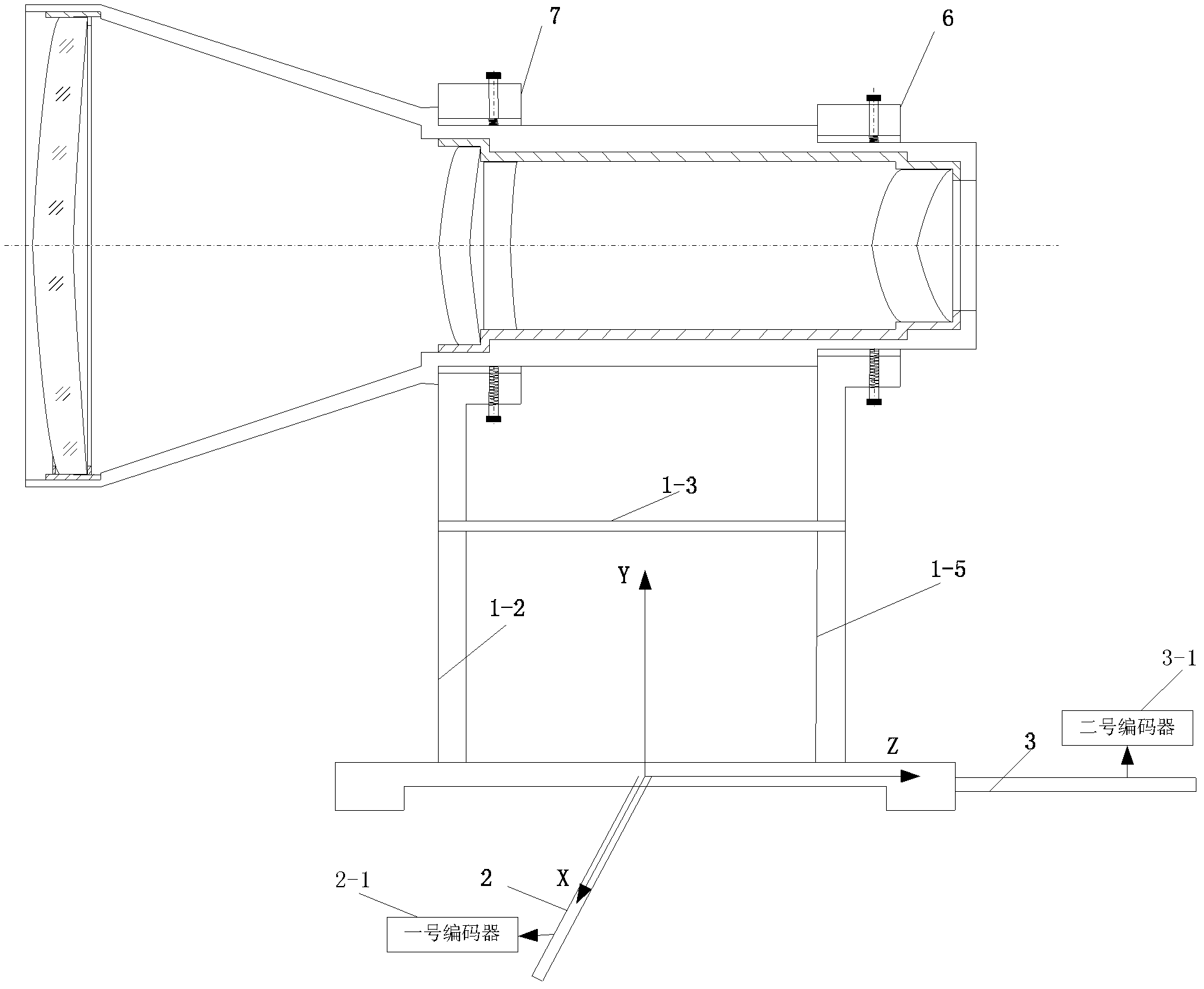

[0008] Specific implementation mode one: combine figure 1 and image 3 Describe this embodiment, this embodiment includes support base 1, No. 1 horizontal lead screw motor 2, No. 2 horizontal lead screw motor 3, No. 1 horizontal position sensor 4, No. 2 horizontal position sensor 5, No. 1 positioning and fixing ring 6, No. 2 positioning fixing ring 7, No. 1 positioning adjusting screw 6-3, No. 2 positioning adjusting screw 6-4, No. 3 positioning adjusting screw 7-3 and No. 4 positioning adjusting screw 7-4, No. 1 horizontal position sensor 4 setting On the No. 1 horizontal lead screw motor 2, the No. 1 horizontal lead screw motor 2 is connected to the bottom X-axis direction of the support base 1, the No. 2 horizontal position sensor 5 is arranged on the No. 2 horizontal lead screw motor 3, and the No. 2 horizontal lead screw motor The motor 3 is connected to the Z-axis direction at the bottom of the support base 1, the No. 1 positioning fixing ring 6 and the No. 2 positionin...

specific Embodiment approach 2

[0012] Specific implementation mode two: combination figure 1 and image 3 To illustrate this embodiment, the support base 1 of the first embodiment includes a horizontal base 1-1, a No. 1 vertical support plate 1-2, a No. 2 vertical support plate 1-5, and a horizontal fixed plate 1-3. No. 1-2 and No. 2 vertical support plates 1-5 are fixed on the two ends of the upper surface of the horizontal base 1-1 along the Z-axis direction, and the two ends of the horizontal fixed plate 1-3 are fixed on No. 1 vertical support plates 1-2 and No. 2 vertical support plates. No. vertical support plates 1-5 are in the middle of the opposite side surfaces. Other components and connections are the same as those in Embodiment 1.

specific Embodiment approach 3

[0013] Specific implementation mode three: combination figure 1 Describe this embodiment. The difference between this embodiment and Embodiment 1 is that it also includes No. 1 elastic fixing screw 6-1, No. 2 elastic fixing screw 6-2, No. 3 elastic fixing screw 7-1, and No. 4 elastic fixing screw 7-2, No. 1 locking screw 6-5 and No. 2 locking screw 7-5, No. 1 elastic fixing screw 6-1, No. 2 elastic fixing screw 6-2, No. 3 elastic fixing screw 7-1, and No. 4 elastic fixing screw The front ends of No. 1 elastic fixing screw 7-2, No. 1 snap screw 6-5 and No. 2 snap screw 7-5 are springs, No. 1 elastic fixing screw 6-1, No. The rear ends of the elastic fixing screw 7-1, the fourth elastic fixing screw 7-2, the first locking screw 6-5 and the second locking screw 7-5 are fixing screws, and the screws are screwed on the fixing ring in the radial direction And the front end penetrates the fixing ring, the No. 1 elastic fixing screw 6-1 is located at the right end of the No. 1 positi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com