Device and method for carrying out field measurement on wave aberration of projection objective of photoetching machine adopting extended light sources

A technology of projection objective lens and extended light source, which is applied in the field of optical measurement, can solve the problems of low light source utilization rate, influence on measurement accuracy, poor light transmittance, etc., and achieve the effect of improving measurement accuracy, eliminating influence, and high utilization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

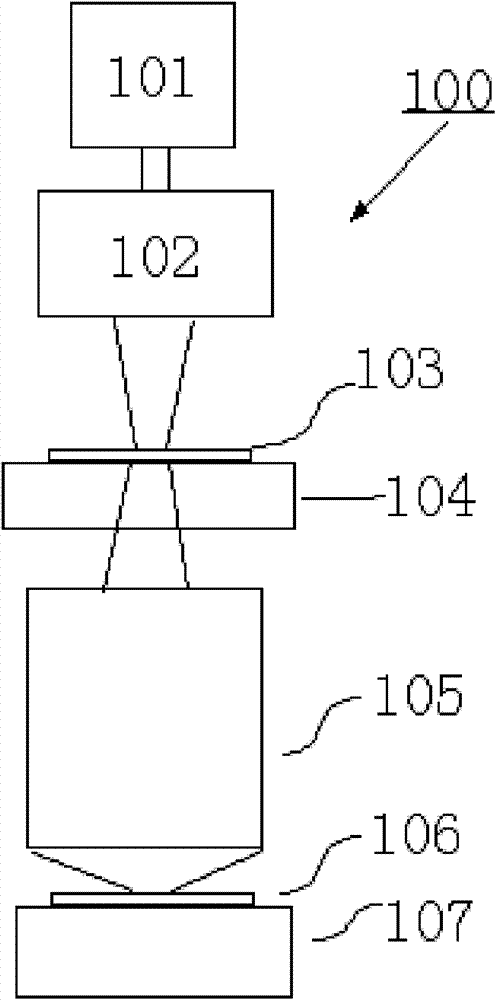

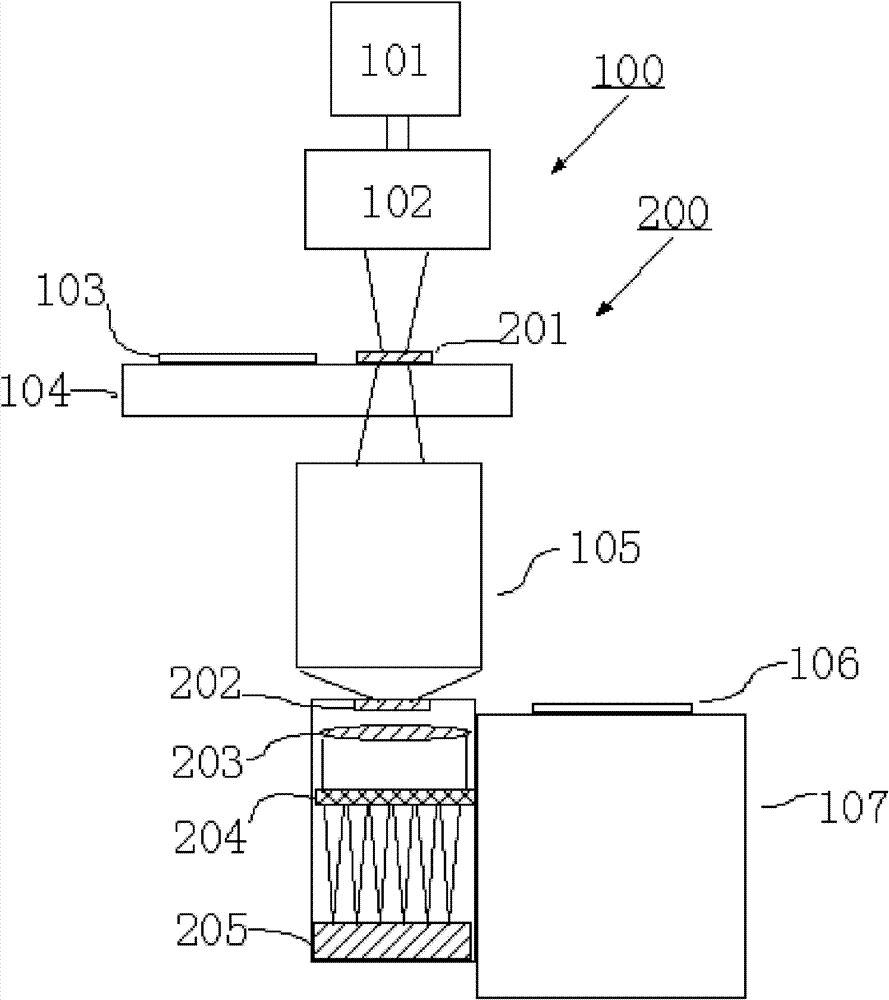

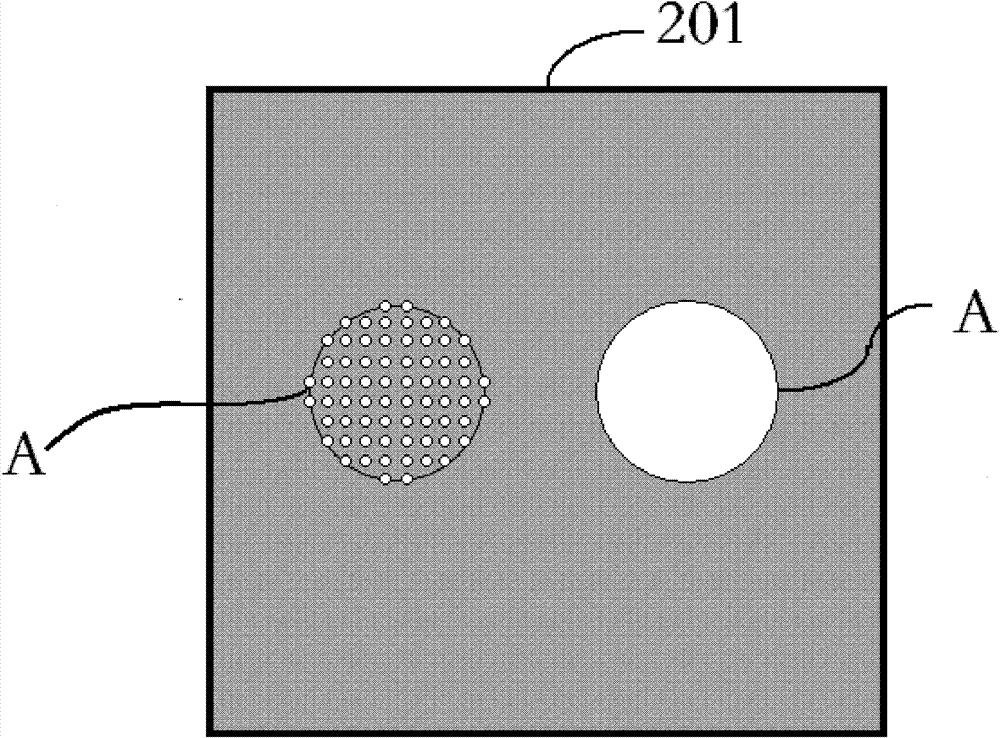

[0032] First introduce the lithography machine system, its structure diagram is as follows figure 1 As shown, it includes: a light source 101 , an illumination system 102 , a mask 103 , a mask stage 104 , a projection objective lens 105 , a silicon wafer 106 and a silicon wafer stage 107 .

[0033]The working principle of the lithography machine is as follows: after passing through the illumination system 102, the light emitted by the light source 101 is irradiated on the mask 103, and the pattern on the mask 103 is passed through the projection objective lens 105, and the projection is reduced in a "step-scan" manner. On the silicon wafer 106 coated with photoresist, so as to realize the pattern transfer. Wherein, the light source 101 is an excimer laser light source, such as an ArF excimer laser with a wavelength of about 193 nm or a KrF exc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com