Sugarcane leaf peeling machine

A defoliator and sugarcane technology, applied in harvesters, agricultural machinery and implements, applications, etc., can solve problems such as damage to sugarcane, inability to automatically adjust distance, and unclean defoliation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

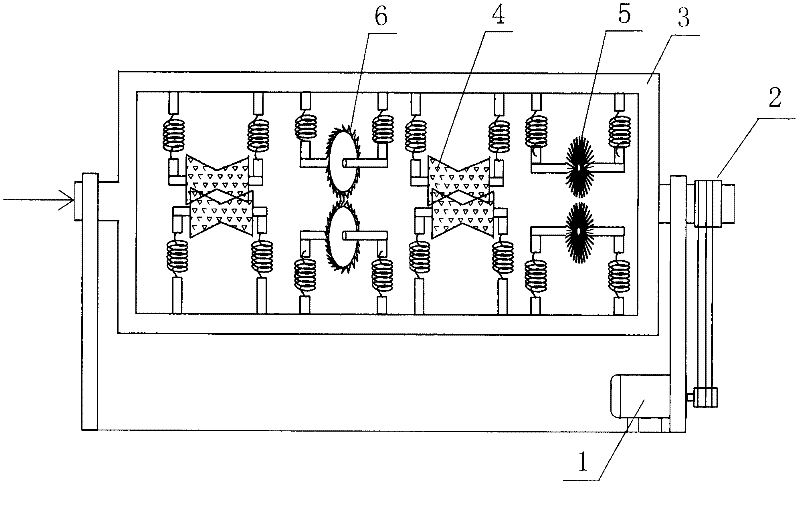

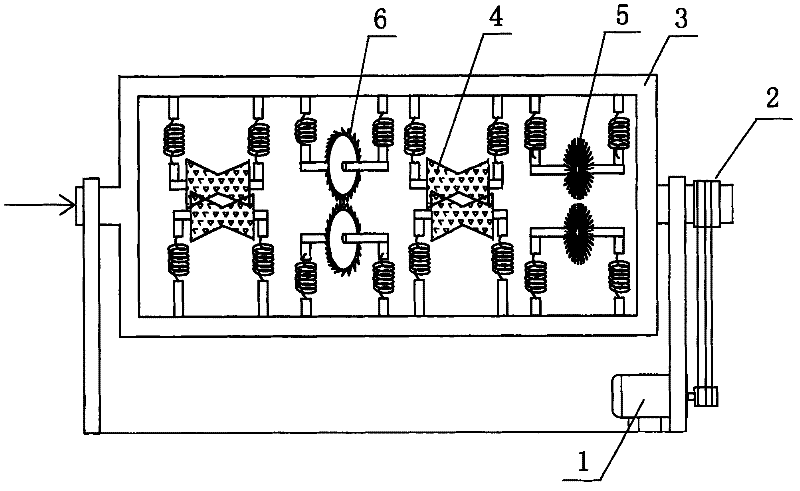

[0014] like figure 1 As shown, the sugarcane leaf stripper of the present invention is driven by the power source 1 to rotate the transmission wheel 2, and the transmission wheel 2 drives the leaf stripping rotating shaft 3 to rotate. 6. There is elasticity between the contact surface with the sugarcane, so it can automatically adjust the distance according to the size and curvature of the sugarcane, without affecting the friction surface and friction force between them. The sugarcane leaves fall off due to the pulling of the rough cylindrical concave wheels by the friction roller and the soft sweep pulley 5. At the same time, because the rough cylindrical concave wheels 4 are arranged in a spiral side lying shape, they undergo pressure rolling, contact friction, etc. The stressed sugarcane will automatically move backwards and spit out the machine. Owing to being equipped with soft sweep type puller 5 and drawing knife 6, so the sugarcane leaves that come off are chopped and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com