Self-adaptation fruit and vegetable peeler and processing method and application thereof

A self-adaptive, peeling machine technology, applied in applications, peeling of vegetables or fruits, food processing, etc., can solve the problems of discoloration of pepper seeds, low peeling efficiency, lack of peeling machines, etc., and achieve high efficiency and timely color protection Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

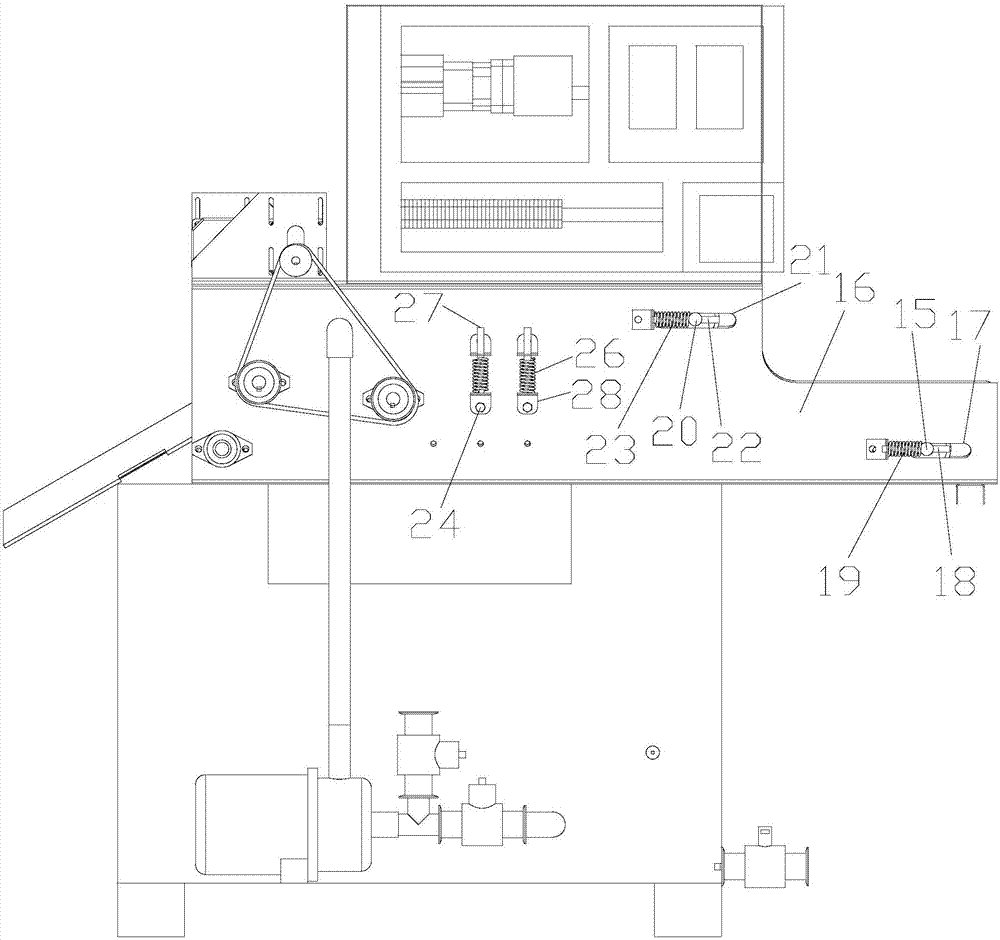

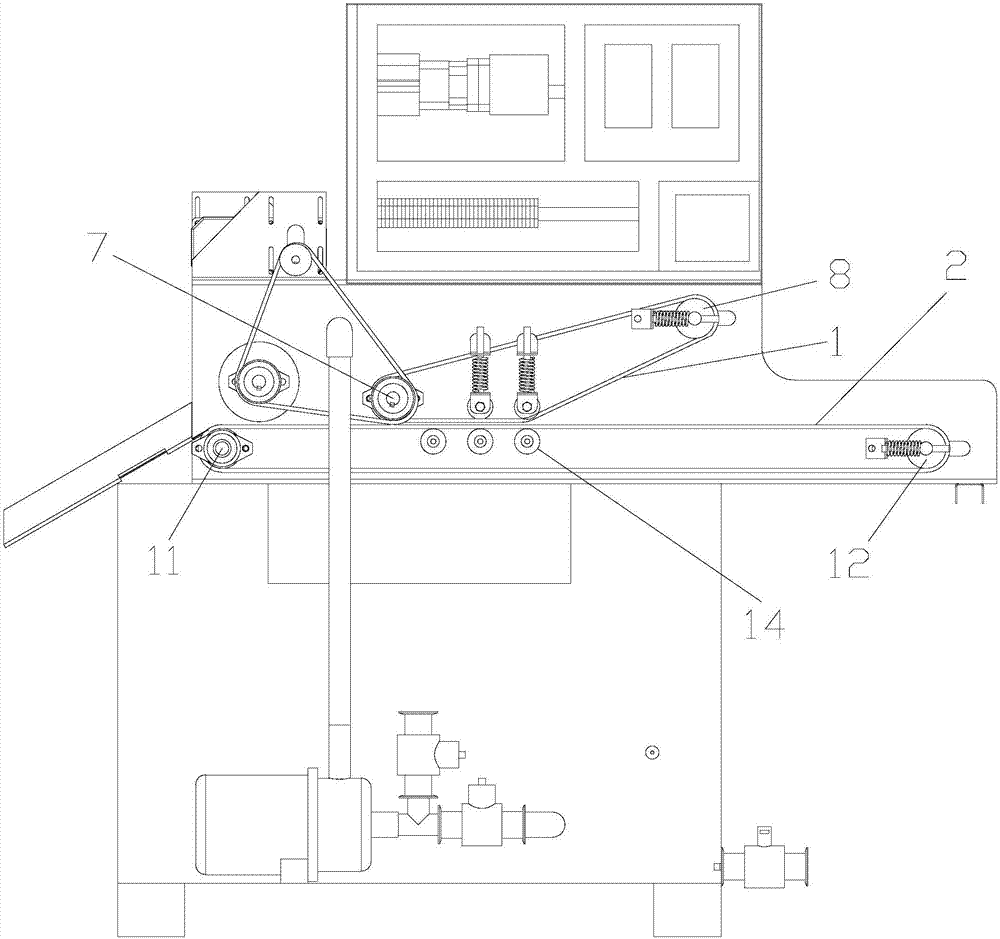

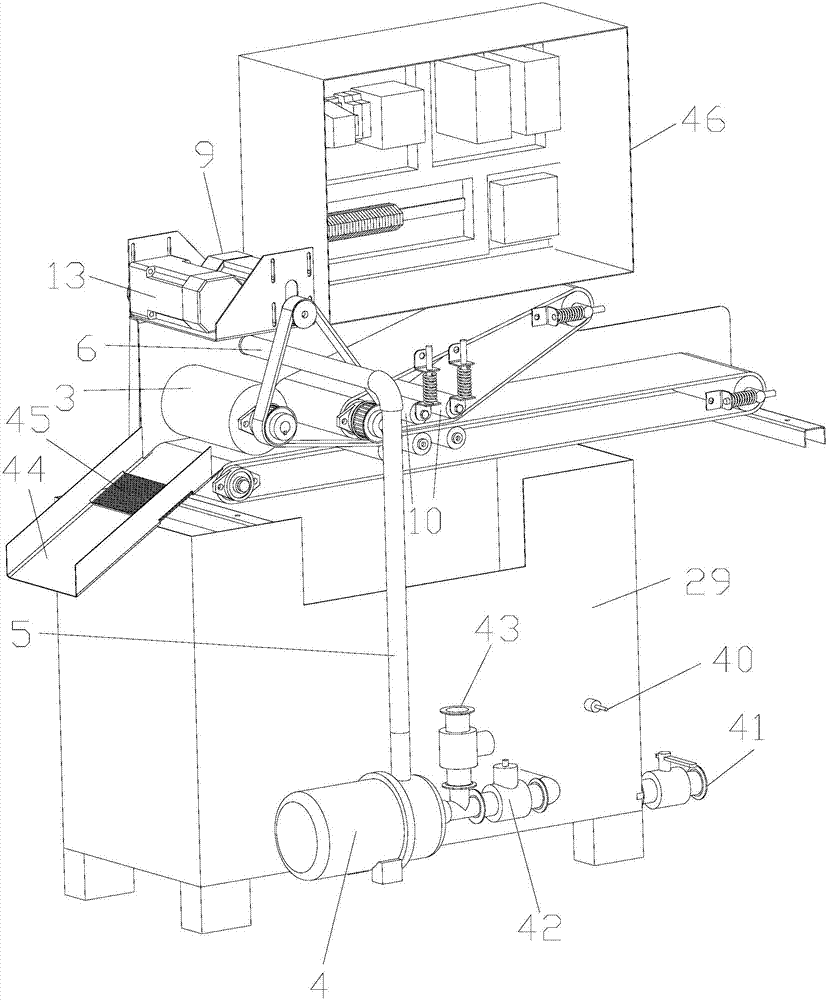

[0038] Such as Figure 1-Figure 6 The self-adaptive peeling machine for fruits and vegetables includes an anti-skid climbing twist conveyor belt 1, an anti-skid horizontal twist conveyor belt 2, a brush wheel 3, a water pump 4, a pipeline 5 and a spray pipe 6. The conveyor belt 1 is positioned above the non-slip horizontal twisting conveyor belt 2, the bottom surface of the non-slip climbing and twisting conveyor belt 1 is a horizontal section, the brush wheel 3 is installed above the rear end of the non-slip horizontal twisting conveyor belt 2, and the water pump 4 is connected to the pipeline 5. Pipeline 5 connects spray pipe 6, and spray pipe 6 is positioned between antiskid climbing and twisting conveyer belt 1 and brush wheel 3, and the spray mouth of spray pipe 6 is downward.

[0039] The two ends of the non-slip climbing twisting conveyor belt 1 are provided with a first driving wheel 7 and a first driven wheel 8, and the first motor 9 drives the brush wheel 3 and the f...

Embodiment 2

[0058] In order to achieve a better peeling effect, multiple anti-skid climbing twisting conveyor belts can be set. In this embodiment, there are 5 non-slip climbing and twisting conveyor belts arranged equidistantly along the processing direction, and there are 5 first motors, and along the direction of fruit and vegetable advancement, the speeds of the 5 first motors decrease gradually, which can reach Better peeling effect.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com