Front feeding system of biomass power plant furnace

A feeding system and biomass technology, which is applied in the field of biomass power plant furnace feeding system, can solve the problems of high cost, various and disorderly sources of biomass, and not easy to be fully broken, and achieve good energy saving and environmental protection effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

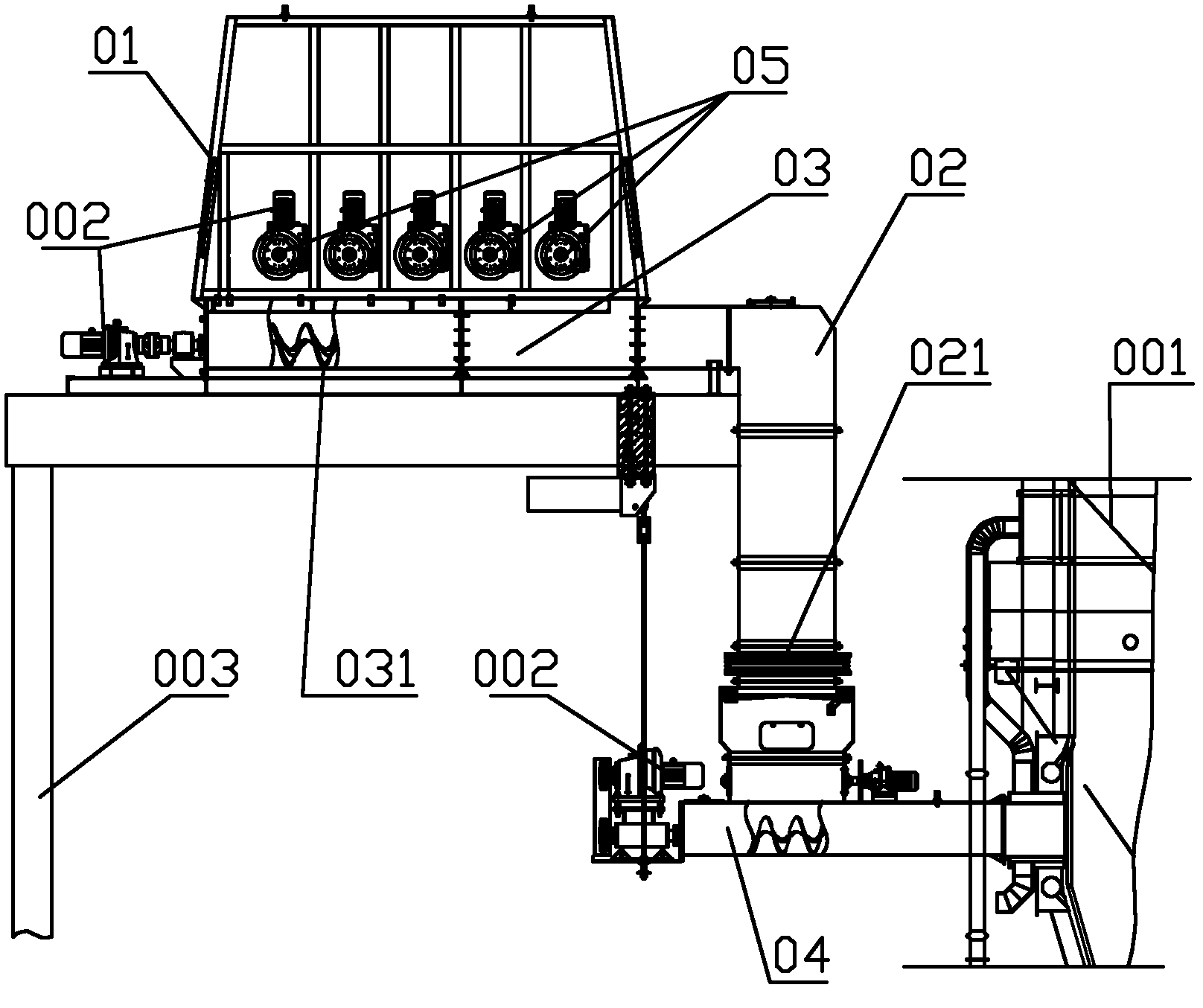

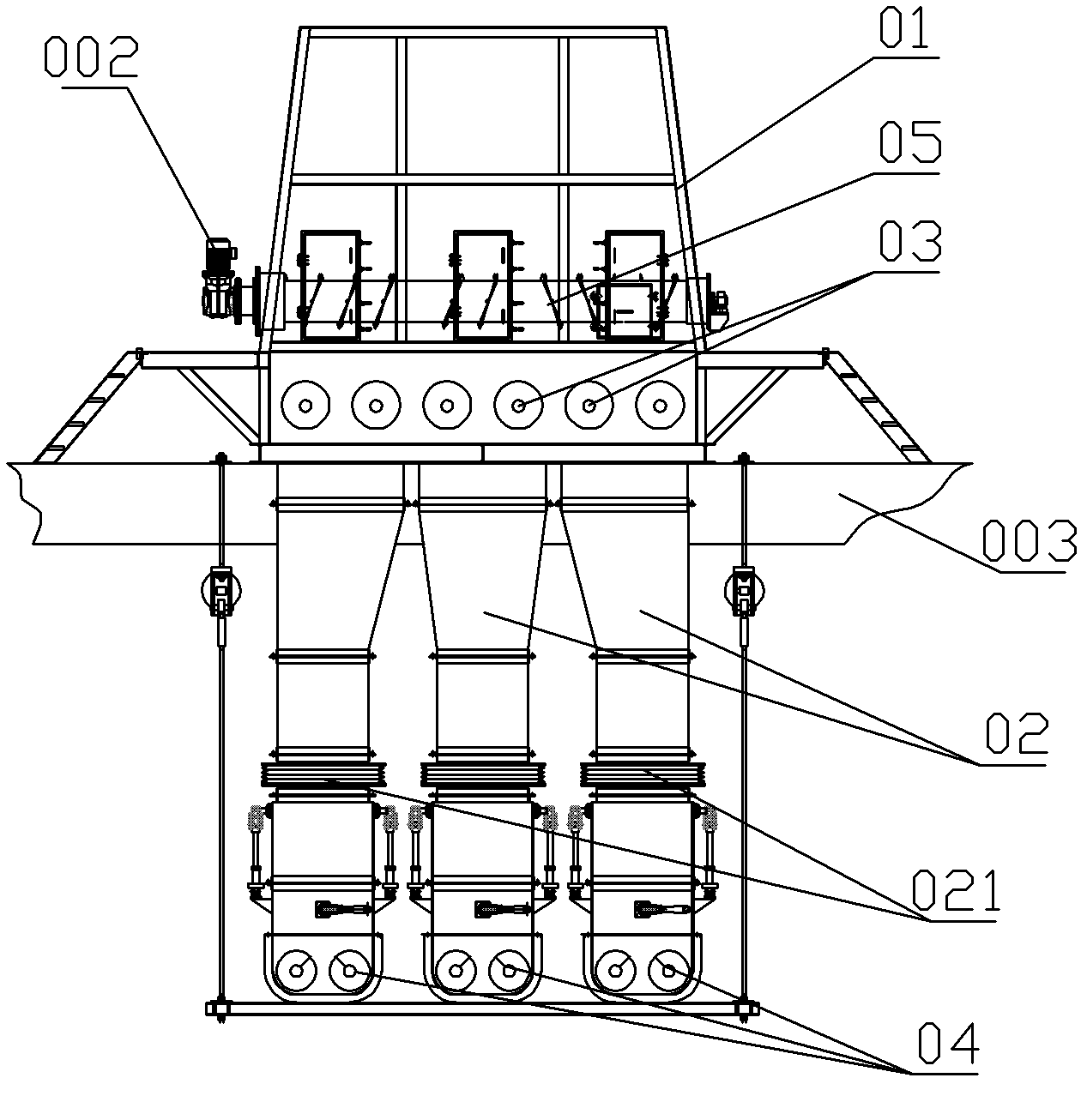

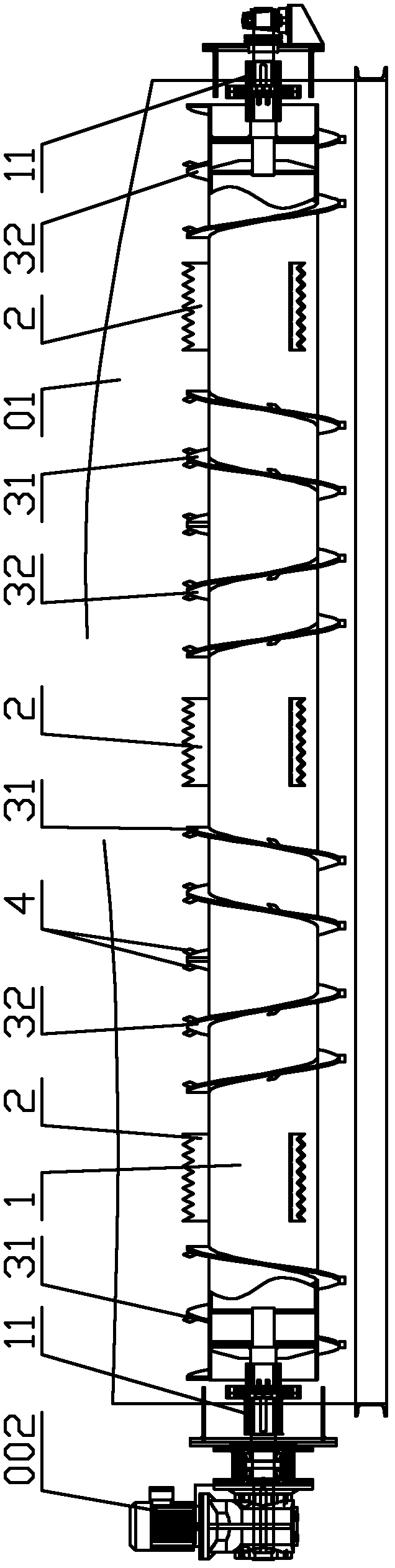

[0020] Such as figure 1 and figure 2 As shown, it is an embodiment of the feeding system in front of the furnace of a biomass power plant of the present invention, including a feeding bin 01, a primary horizontal feeding mechanism located at the bottom of the feeding bin, and a secondary horizontal feeding mechanism that feeds the incinerator 001, The first-level horizontal feeding mechanism and the second-level horizontal feeding mechanism are connected through the vertical slide pipe 02, and the thermal displacement compensation device 021 is installed on the bottom section of the slide pipe, and the lower part of the feeding bin is located above the first-level horizontal feeding mechanism. Biomass silo shifter, the first-level horizontal feeding mechanism is composed of several first-level shaftless screw feeders 03 arranged in parallel and driven by motors. In this embodiment, there are 6 sets, each of which is a first-level shaftless screw feeder The outlet of the feed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com