Electronic device shell

A technology for electronic devices and housings, which is applied to electrical equipment housings/cabinets/drawers, electrical components, housings with display/control units, etc. Product cost increase and other issues, to achieve the effect of enhancing added value and use value, enhancing overall sense and beautiful appearance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

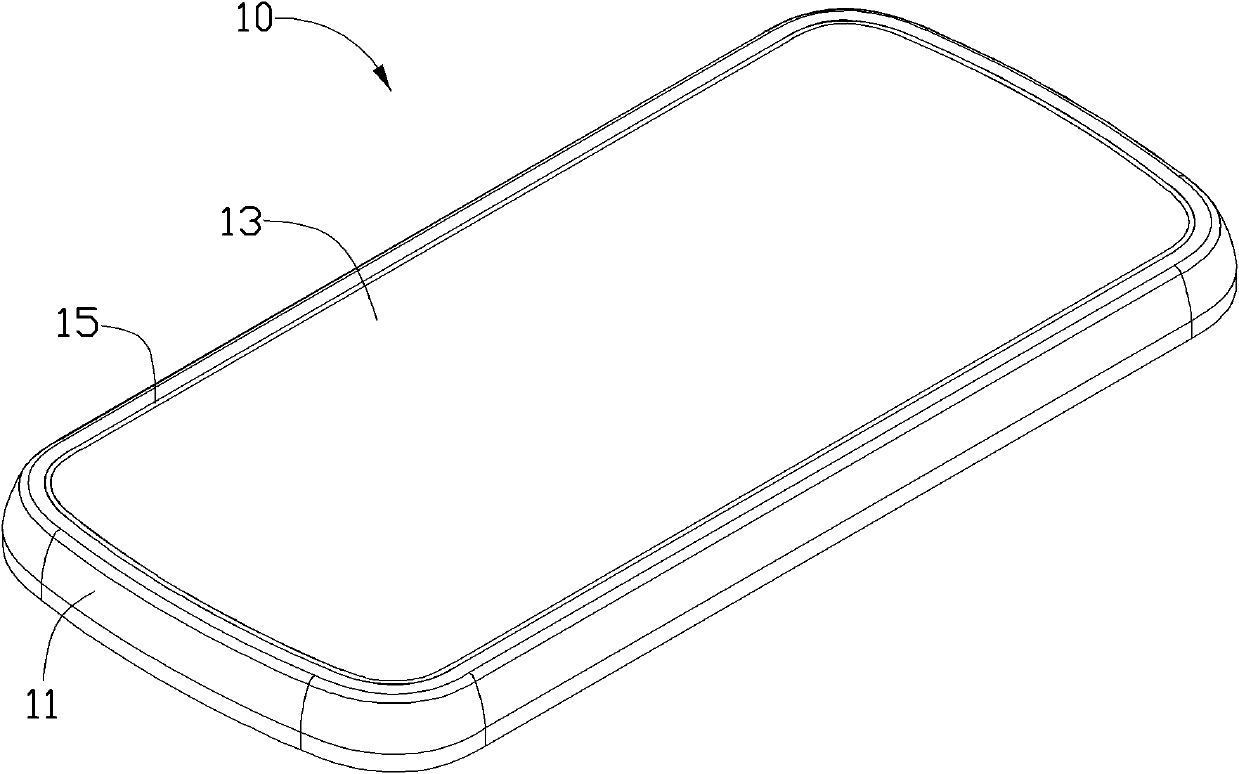

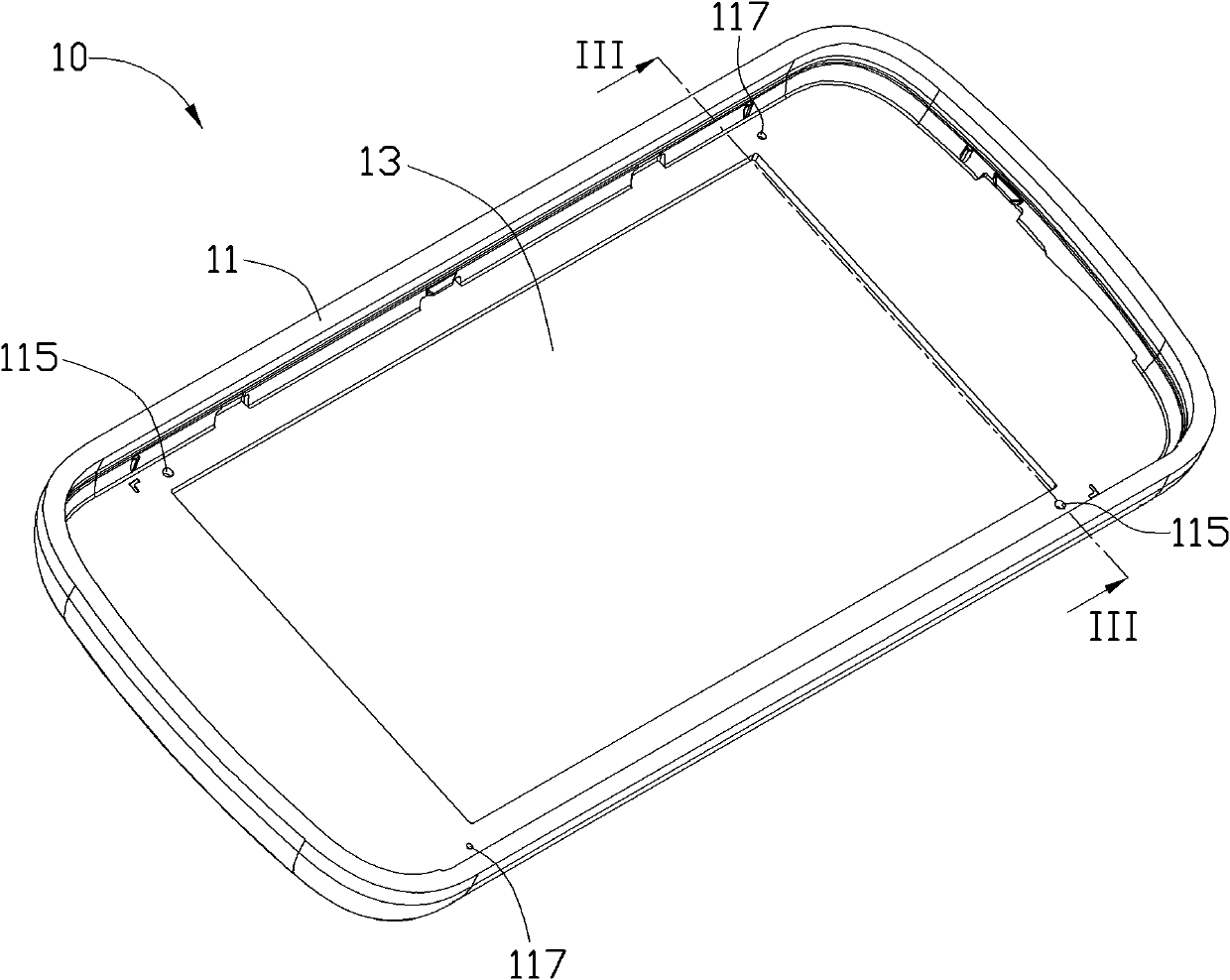

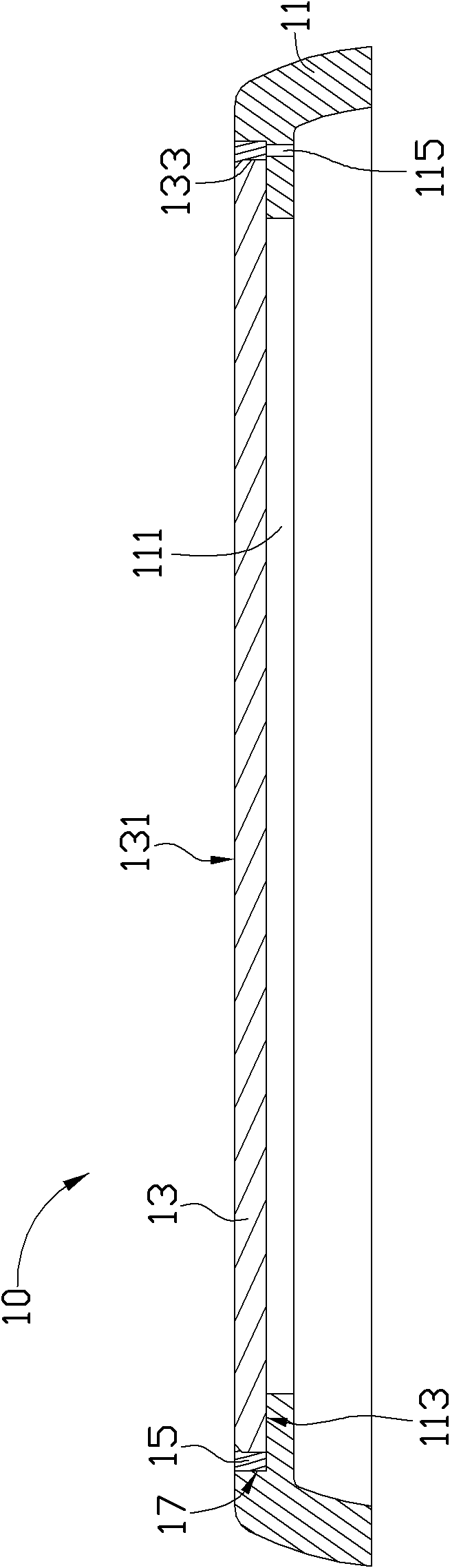

[0024] see Figure 1 to Figure 3 , The housing 10 of the electronic device according to a preferred embodiment of the present invention includes a housing part 11 , a window part 13 and an adhesive layer 15 . The window piece 13 is installed in the casing piece 11 , and the adhesive layer 15 is formed between the window piece 13 and the casing piece 11 .

[0025] The housing part 11 can be produced by injection moulding. The plastic used for injection molding the housing part 11 may be polycarbonate (PC), polymethyl methacrylate (PMMA) or polyamide (PA). These plastics have strong impact and scratch resistance.

[0026] The housing member 11 is formed with a rectangular window portion 111 . A step 113 is formed around the periphery of the window part 111 of the casing part 11 , and the step 113 is used for carrying the window part 13 . A plurality of openings are formed on the step 113 adjacent to the window portion 111 , and the plurality of openings include a plurality o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com