Mount for solar cell module, and photovoltaic power generation system using the mount

A solar cell and pedestal technology, applied in the field of solar power generation systems, can solve the problems of small protrusions being skewed or crushed, weak in strength, and skewed, and achieve the effect of eliminating cumbersome operations and stably grounding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0047] Hereinafter, embodiments of the present invention will be described in detail with reference to the drawings.

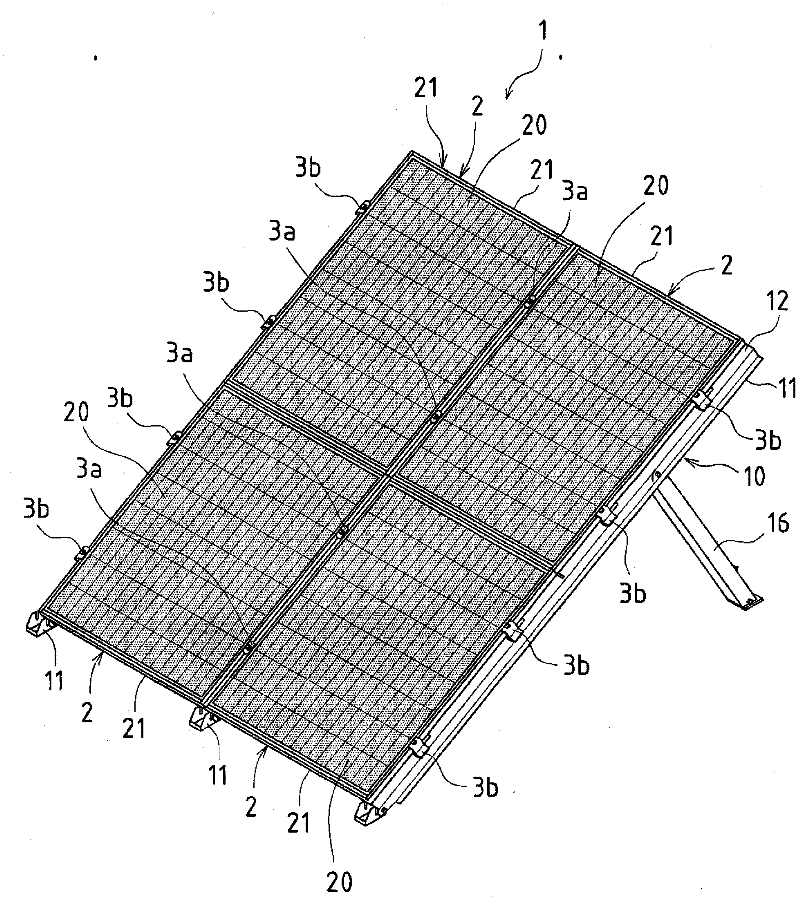

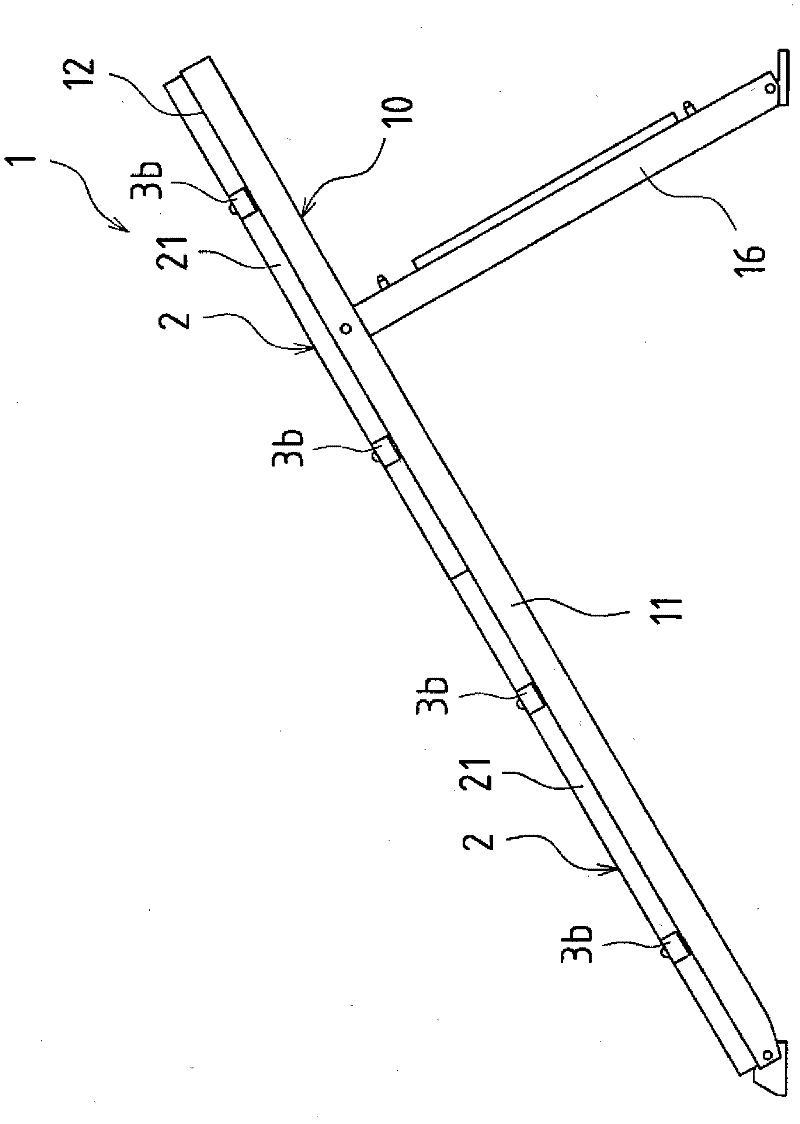

[0048] figure 1 It is a perspective view showing the first embodiment of the base of the solar cell module of the present invention. in addition, figure 2 It is a side view showing the base unit of the first embodiment.

[0049] In the base 1 of the solar cell module of the present embodiment, three such as figure 2 Shown base unit 10, these base units 10 are arranged side by side on roof, ground etc., as figure 1 As shown, four solar cell modules 2 are placed and fixed on each base unit 10 .

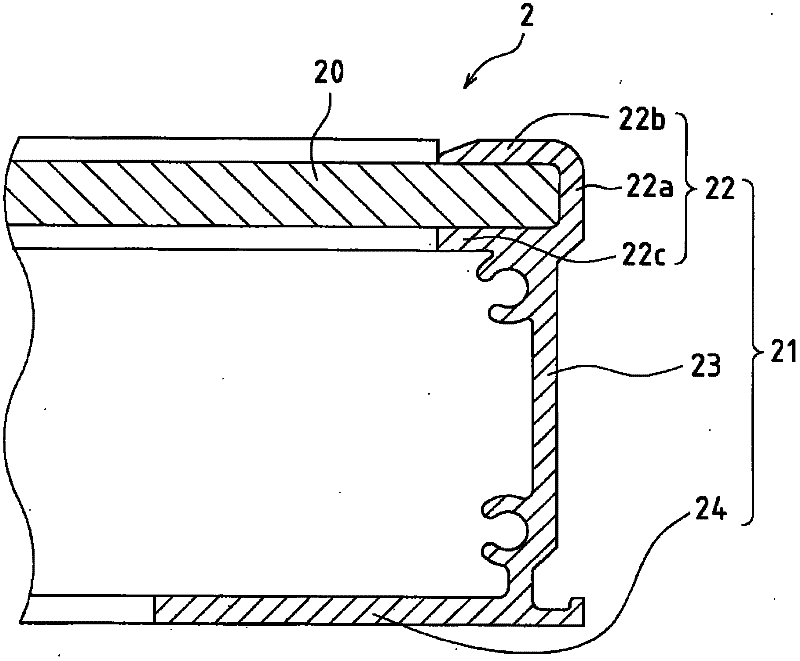

[0050] The solar cell module 2 is composed of a solar cell panel 20 and a frame member 21 holding the solar cell panel 20 .

[0051] Such as figure 2 As shown, the base unit 10 is composed of a mounting bracket 11 and a longitudinal bracket 16, and is formed in an inclined T-shape when viewed from the side. That is, one base unit 10 is formed by fixing the fro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com