Viscous shear damping strut assembly

A strut and damping technology, applied in the direction of elastic suspension, vehicle components, fluid resistance brakes, etc., can solve problems such as fluid leakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The disclosure is capable of embodiments in different forms, the drawings illustrate and embodiments of which will be described in detail herein, but it is to be understood that the description is to be considered as an illustration of the principles of the disclosure and is not intended to be exhaustive or to limit the disclosure. Details of the construction and arrangement of the components described and shown in the drawings are described below.

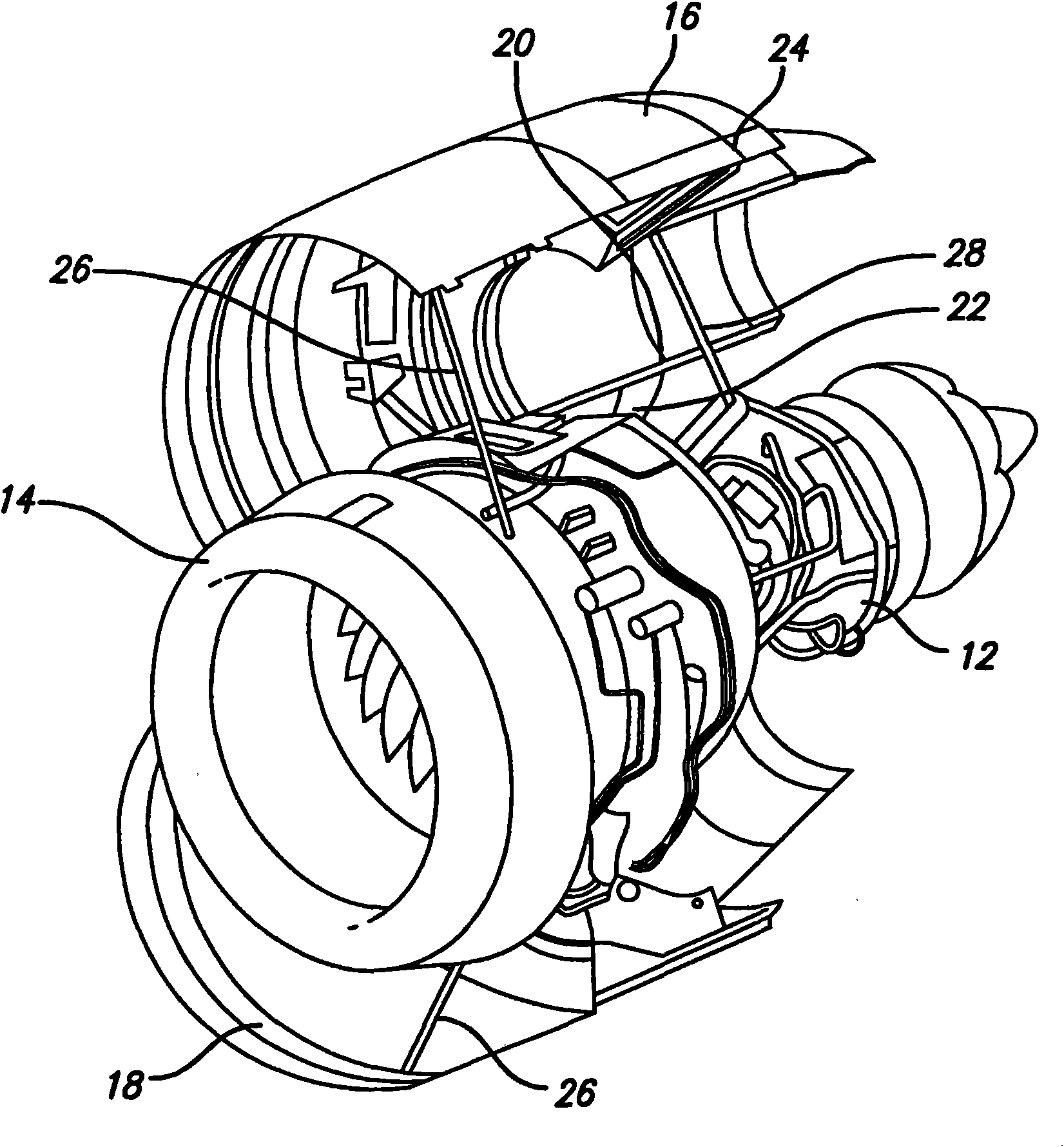

[0032] Such as figure 1 As shown, an aircraft jet engine 12 is generally surrounded by a large cylindrical structure 14 which generally includes one or a pair of aircraft panels or nacelles 16 and 18 . Aircraft engine cowls 16 and 18 are typically mounted by hinges 20 to an engine support structure 22 , such as where an engine can be mounted to the aircraft via an engine pylon. Hoods 16 and 18 are hinged such that they can pivot to provide maintenance and repair access to engine 12 . During aircraft operation, the cowls 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com