Suspension spray arm structure for uncovering-type dish washing machine

A dishwasher and suspension technology, applied in the field of suspension spray arm structure, can solve the problems of low rotation efficiency, slow spray arm rotation speed, easy wear and tear of the central shaft, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

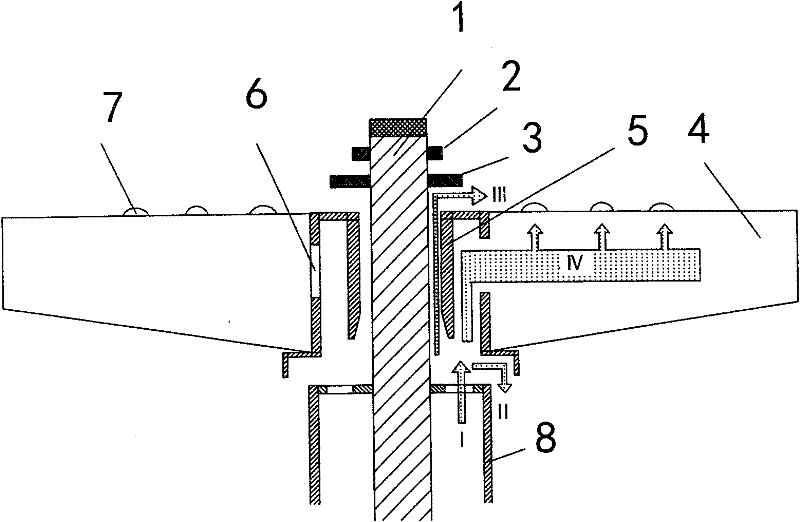

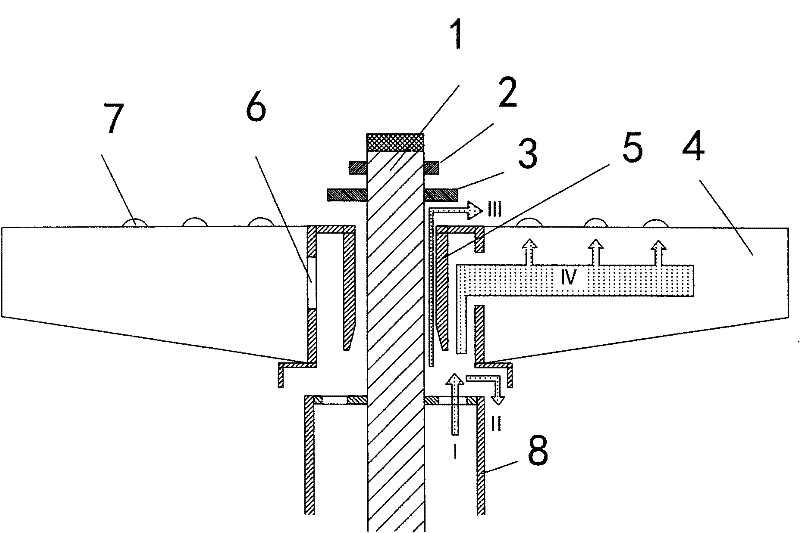

[0016] In the embodiment of the present invention shown in the drawings, it includes a spray arm 4 with a water supply cavity 6 inside and a spray hole 7 connected to the internal water supply cavity on the upper surface. The water distribution jacket 5 is movably installed on the central shaft 1. The inner diameter of the water distribution jacket 5 is 2mm larger than the outer diameter of the central shaft. The lower end of the water distribution jacket 5 is separated from the upper end of the water supply sleeve 8, and the water distribution jacket 5 is supported on the water supply jacket. Tube 8 on. Gasket 3 and circlip 2 are installed on the upper side of the water distribution jacket 5. The gasket 3 has an appropriate distance from the water distribution jacket 5, and is used to limit the position of the spray arm 4. When the water is pressurized by the water pump to the water supply casing 8 , the water flow has three directions, one is to enter the water supply cavity...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com