Method for automatically forming encircling plate of refrigerator

A forming method and technology of hoarding, applied in the field of sheet metal forming, can solve the problems of workers with many operating procedures, low efficiency, and unfavorable large-scale production, and achieve the effect of improving work efficiency, improving production efficiency, and achieving continuity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

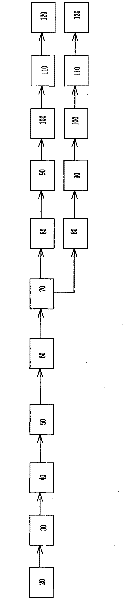

Method used

Image

Examples

Embodiment Construction

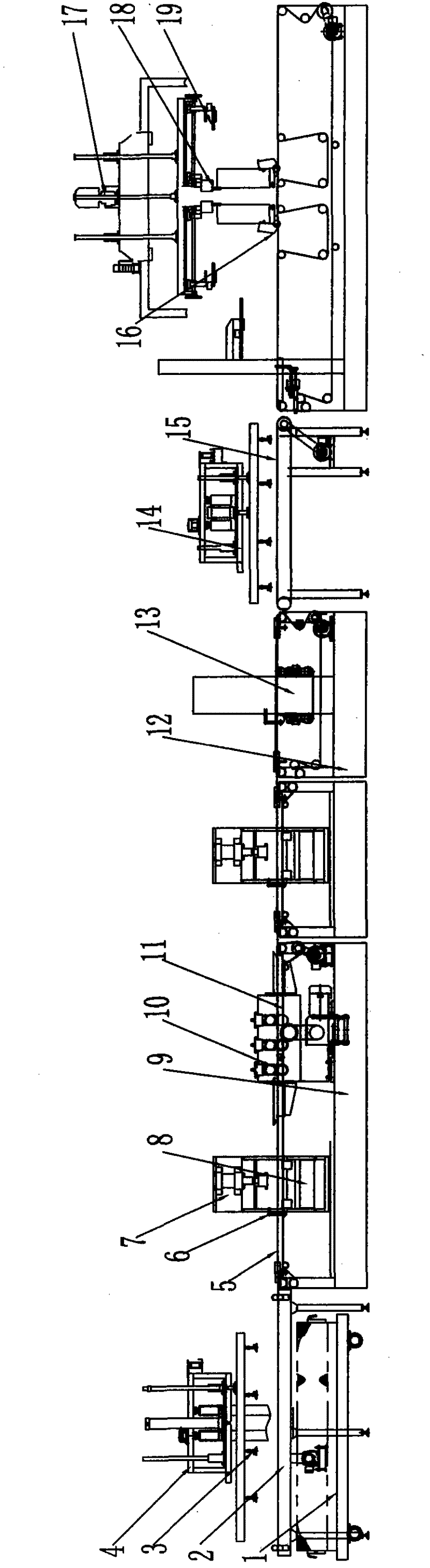

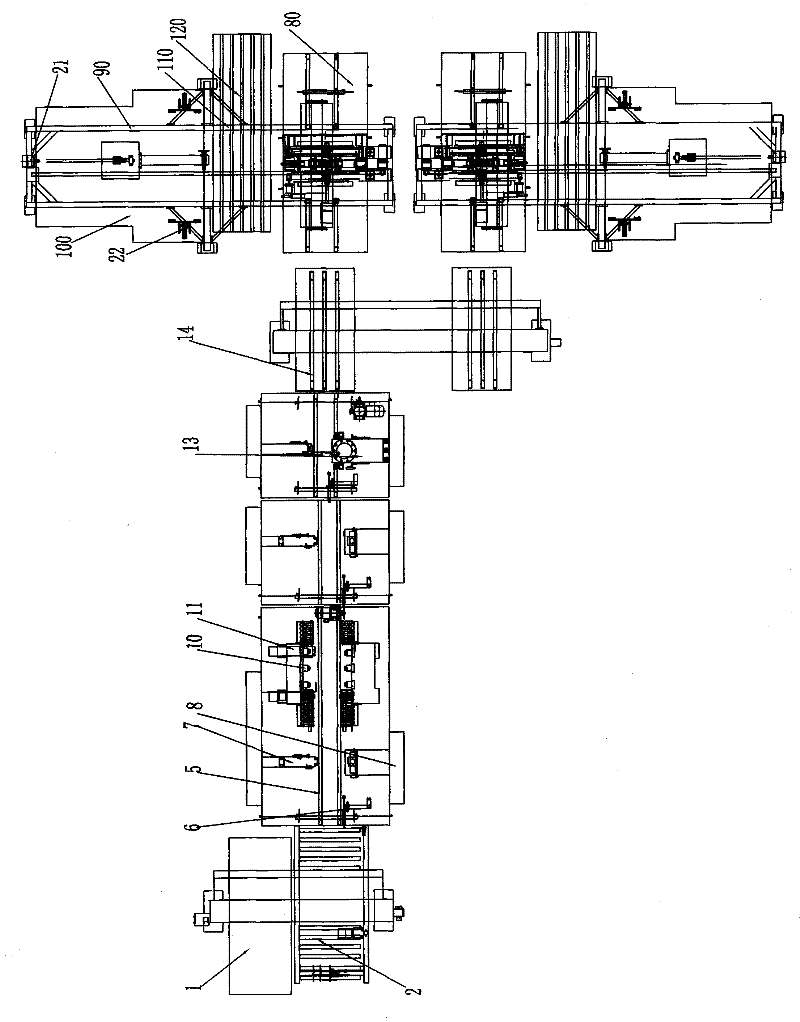

[0020] The present invention will be further described below in conjunction with the accompanying drawings and implementation examples.

[0021] 1. Feeding

[0022] The working process of the feeder 20 is: the sheets accumulated on the loading trolley 1 are sucked up to a certain height by the suction cup assembly 3, and then transferred to the power conveying line 2 through the conveying frame body 4, and then released by the cylinder Side positioning of the sheet.

[0023] The height of the sheet material on the loading trolley 1 is 0-300mm, and the loading trolley 1 is provided with a magnetic material distribution mechanism. The loading trolley 1 is manually driven in and out in the direction of the line body, and walks on two guide rails whose working surfaces are located above the plane.

[0024] The up and down movement of the suction cup frame is driven by the cylinder, and the horizontal movement is driven by the motor reducer. There are 12 sets of suction cups in t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com