Discharge lip brick for crystal glass bubble column

A crystal glass and lip brick technology, applied in glass production, glass furnace equipment, glass manufacturing equipment, etc., can solve the problems of low margin, low production capacity, and inability to discharge materials from multiple channels, and achieve the effect of reducing costs and facilitating adjustment.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

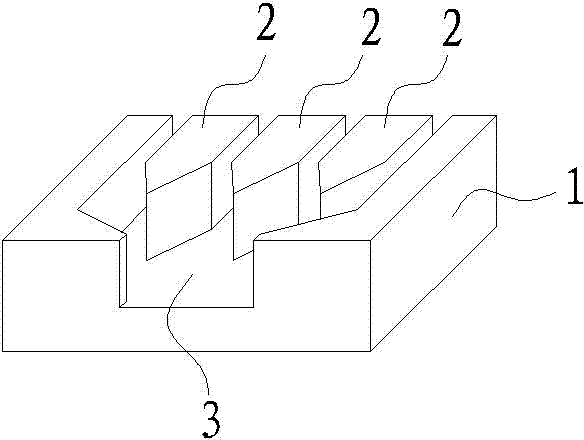

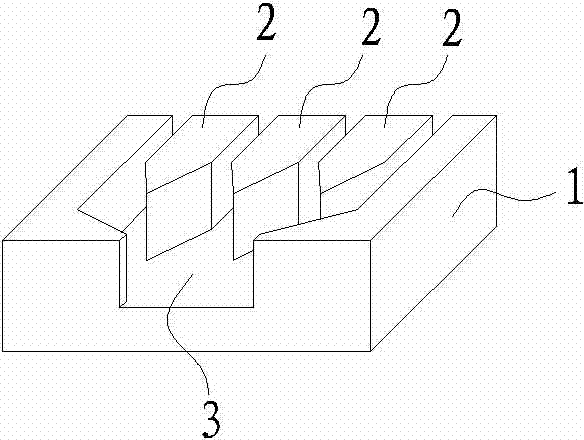

[0009] As shown in the accompanying drawings, the crystal glass bubble column discharge lip brick of the present invention comprises a square lip brick body 1 made of refractory material, the surface of the lip brick body has a glass liquid flow channel 3, and the glass liquid flow channel There are three stoppers 2 arranged parallel to each other at the outlet of the outlet, and the stoppers divide the molten glass flow channel into four parallel flow channels to form a four-channel discharge lip brick. The stoppers are square The conical structure and the tip of the cone face the entrance of the molten glass flow channel, so as to facilitate the diversion of the molten glass. The crystal glass bubble column discharge lip brick of the present invention can not only increase the output of products without changing any equipment, and the output of single-machine products is increased by 13%-20% compared with the past, but also facilitates the adjustment of product varieties and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com