Air inlet vortex adjusting structure of diesel engine

A technology for adjusting structure and diesel engine, applied in mechanical equipment, exhaust gas recirculation, engine components, etc., and can solve problems such as abnormal local swirl ratio

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

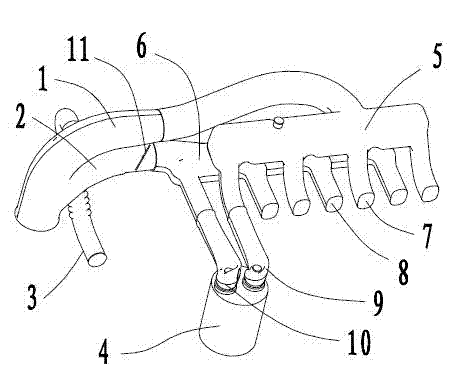

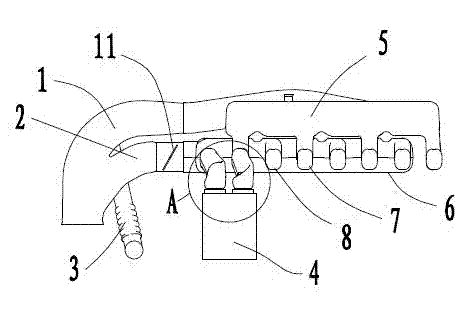

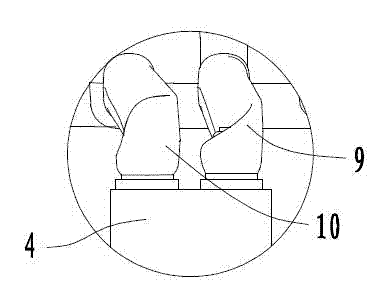

[0019] Embodiment: a kind of diesel engine intake swirl adjustment structure, such as figure 1 , figure 2 , image 3 shown. figure 1 , figure 2 It is a structural diagram of the intake port in the cylinder head of a diesel engine, in which the entity of the cylinder head is removed, and the hollow structure of the intake port is retained. figure 1 , figure 2 In the center, the leftmost is the inlet of the intake port, which communicates with the outside of the cylinder head. The inner side of the inlet is bifurcated into a high-swirl intake pipe 1 and a low-swirl intake pipe 2. The side of the high-swirl intake pipe 1 is connected to an EGR intake pipe 3. An adjustable flow valve 11 is arranged in the swirl intake pipe 2 . The high swirl intake pipe 1 is connected to the high swirl pressure stabilizing chamber 5, and is bifurcated into four high swirl intake manifolds 7 on the other side of the high swirl flow stabilizing chamber 5; the low swirl intake pipe 2 is conne...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com