Dust-free production method of narrow-distillation-range low-viscosity insulating oil

A production method and low-viscosity technology, which are used in the petroleum industry, hydrocarbon oil treatment, and multi-stage series refining process treatment. problems, to achieve the effect of improving the production environment, good anti-oxidation safety, and high mixing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

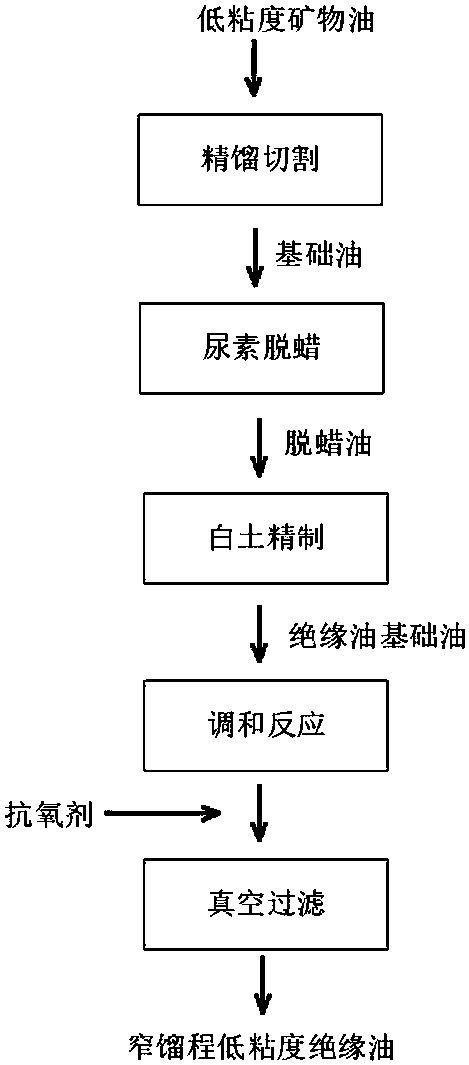

[0048] see figure 1 , a dust-free production method of insulating oil with narrow boiling range and low viscosity, comprising the following steps:

[0049] S1. Distillation and cutting, pump the hydrogenated low-viscosity mineral oil into the rectification tower for rectification and cutting, and cut out the distillate as base oil with a temperature of 300-350°C;

[0050] S2, urea dewaxing, the base oil obtained in S1 is input into the urea dewaxing device, and the dry urea dewaxing process is used for deep dewaxing at a temperature of 25-35°C, and the dewaxed oil produced has a pour point of -25 dewaxed oil at ℃;

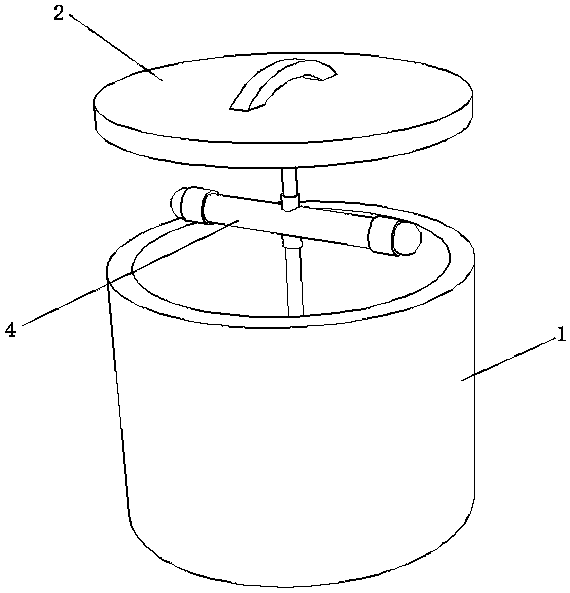

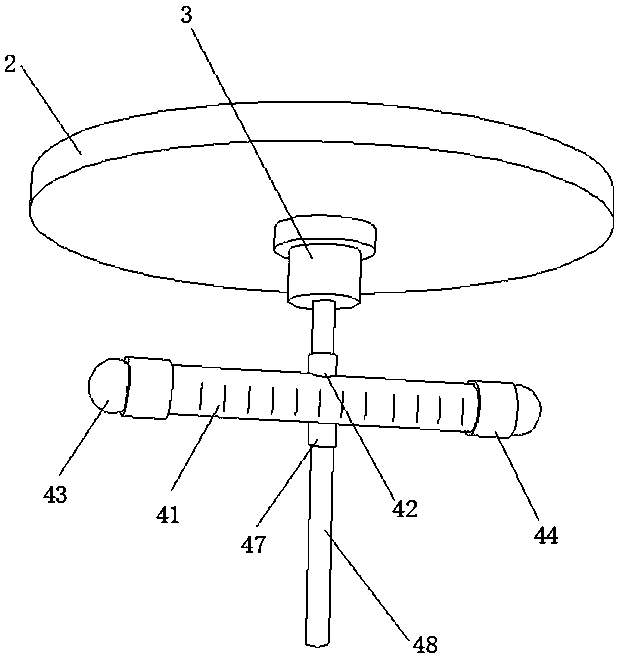

[0051] S3, clay refining, pump the dewaxed oil obtained in S2 into a dust-free clay refining kettle, heat up to 80°C, add the prepared clay with a weight ratio of 3%, heat and stir for 30min, and filter through a filter press to obtain insulating oil base oil;

[0052] S4, blending reaction, pump 5000kg of special base oil into the blending reaction kettle with ...

Embodiment 2

[0055] see figure 1 , a dust-free production method of insulating oil with narrow boiling range and low viscosity, comprising the following steps:

[0056] S1, rectification and cutting, pump the hydrotreated 5# low-viscosity mineral oil into the rectification tower for rectification and cutting, and cut out the base oil whose distillate is 300-345°C;

[0057] S2, urea dewaxing, the base oil obtained in S1 is input into the urea dewaxing device, and the dry urea dewaxing process is used for deep dewaxing at a temperature of 30-40°C, and the dewaxed oil produced has a pour point of -25 dewaxed oil at ℃;

[0058] S3, clay refining, pump the dewaxed oil obtained in S2 into a dust-free clay refining kettle, heat to 70°C, add 2% clay that has been prepared, keep stirring for 20 minutes, and filter through a filter press to obtain insulating oil base oil;

[0059] S4, blending reaction, pump 5000kg of special base oil into the blending reaction kettle with a rotating speed of 80-...

Embodiment 3

[0062] see figure 1 , a dust-free production method of insulating oil with narrow boiling range and low viscosity, comprising the following steps:

[0063] S1, rectification and cutting, pump the refined special white oil into the rectification tower for rectification and cutting, and cut out the distillate as base oil with a temperature of 305-350°C;

[0064] S2, urea dewaxing, the base oil obtained in S1 is input into the urea dewaxing device, and the dry urea dewaxing process is used for deep dewaxing at a temperature of 25-35°C, and the dewaxed oil produced has a pour point of -26 dewaxed oil at ℃;

[0065] S3, clay refining, pump the dewaxed oil obtained in S2 into a dust-free clay refining kettle, heat up to 90°C, add the prepared clay with a weight ratio of 4%, heat and stir for 40min, and filter through a filter press to obtain insulating oil base oil;

[0066] S4, blending reaction, pump 5000kg of special base oil into the blending reaction kettle with a rotation s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Pour point | aaaaa | aaaaa |

| Pour point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com