Optical fiber ribbon coating paste used in band shape optical cable and preparation method thereof

A technology for ribbon optical cable and optical fiber ribbon, which is applied in the field of optical fiber ribbon coating paste for ribbon optical cable and its preparation field, and achieves the effects of strong water resistance, good compatibility and clean production environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

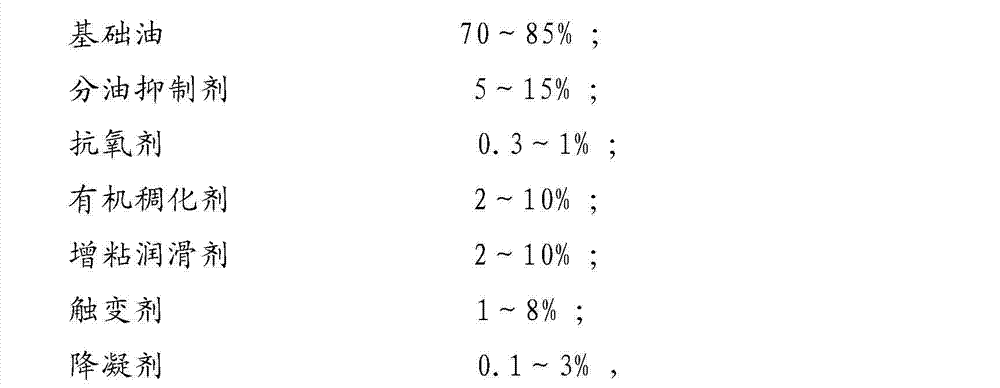

Method used

Image

Examples

Embodiment 1

[0025] First add 2 grams of pour point depressant to 773 grams of mixed oil (300 grams of synthetic oil and 473 grams of Type 3 hydrogenated white oil). After fully and uniformly stirring, add 100 grams of polyisobutylene oil separation inhibitor, heat and stir for 1~ 3 hours, when the temperature rises to 100°C, add 70 grams of organic thickener, continue heating and stirring for 2 to 5 hours, when the temperature rises to 160°C, stop heating, add 30 grams of viscosity-increasing lubricant, keep stirring After 1 to 3 hours, add 5 grams of antioxidant, continue to stir for 0.5 to 1 hour, then cool down to 50°C to 80°C, add 20 grams of thixotropic agent, fully return the material and stir for 1 to 3 hours, then Homogeneous grinding, vacuum degassing, and finally the final product is a colorless transparent colloid.

[0026] Among the above-mentioned raw materials, the pour point depressant is selected from Shanghai Daopu Chemical International Trade Co., Ltd., the product model...

Embodiment 2

[0029] First add 3 grams of pour point depressant to 764 grams of mixed oil (300 grams of synthetic oil and 464 grams of Type 3 hydrogenated white oil), after fully and uniformly stirring, add 110 grams of polybutene oil separation inhibitor, heat and stir for 1 ~3 hours, when the temperature rises to 100°C, add 73 grams of organic thickener, continue to heat and stir for 2 to 5 hours, when the temperature rises to 160°C, stop heating, add 25 grams of viscosity-increasing lubricant, keep warm After stirring for 1 to 3 hours, add 5 grams of antioxidant, continue stirring for 0.5 to 1 hour, then cool down to 50°C to 80°C, add 20 grams of thixotropic agent, fully return the material and stir for 1 to 3 hours, After homogeneous grinding and vacuum degassing, the final product obtained is a colorless transparent colloid.

[0030] Among the above-mentioned raw materials, the pour point depressant is selected from Shanghai Daopu Chemical International Trade Co., Ltd., the product mod...

Embodiment 3

[0033] First add 5 grams of pour point depressant to 759 grams of Type 3 hydrogenated white oil, and after fully and uniformly stirring, add 100 grams of polyisobutylene oil separation inhibitor, heat and stir for 1 to 3 hours, when the temperature rises to 100°C, Add 75 grams of organic thickener, continue to heat and stir for 2 to 5 hours, stop heating when the temperature rises to 160°C, add 30 grams of viscosity-increasing lubricant, keep stirring for 1 to 3 hours, then add 6 grams of antioxidant Add thixotropic agent, continue stirring for 0.5-1 hour, then lower the temperature and cool to 50°C-80°C, add 25 grams of thixotropic agent, fully return the material and stir for 1-3 hours, after homogeneous grinding, vacuum degassing, the final obtained The final product is a colorless transparent colloid.

[0034] Among the above-mentioned raw materials, the pour point depressant is selected from Shanghai Daopu Chemical International Trade Co., Ltd., the product model is NACOF...

PUM

| Property | Measurement | Unit |

|---|---|---|

| oxidation induction time | aaaaa | aaaaa |

| acid value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com