Protection box for circuit board and installation method of protection box

A technology for protecting boxes and circuit boards, which is applied in the fields of coating non-metallic protective layers, secondary treatment of printed circuits, sealing shells, etc., which can solve the problems of uneconomical manufacturing and processing, high time and processing costs, etc., and meet the requirements of guaranteed packaging Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

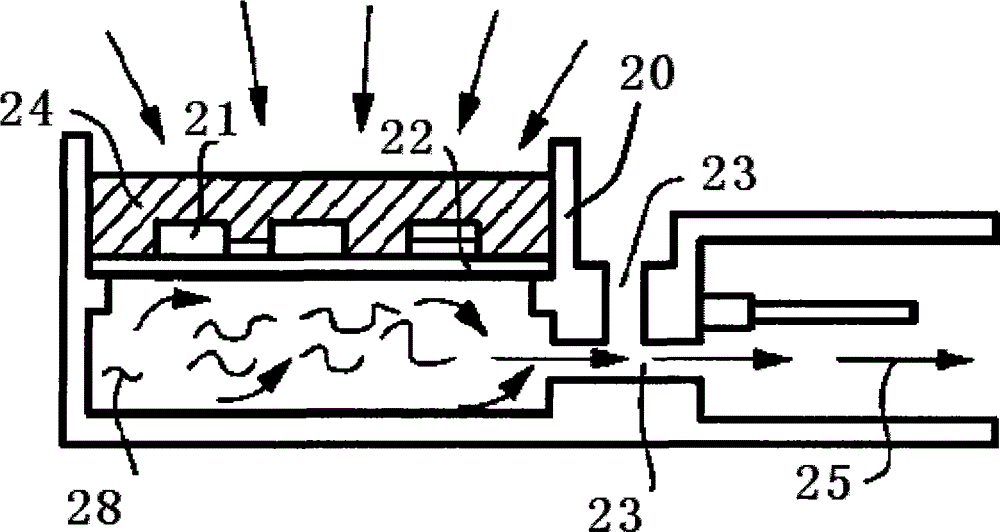

[0018] figure 1 It is a schematic diagram of the prior art. like figure 1 As shown, at first the component 21 of the PCB circuit board 22 is facing up and installed in the upper cavity of the box body 20, that is, the back side of the PCB board 22 faces the lower cavity of the box body 20, and the lower cavity of the box body is provided with an opening 23; then Add resin 24 to the element; then process and cure the resin 24, and the gas 28 in the lower chamber generated during the process is discharged from the opening 23 along the direction of the arrow 25; finally the opening 23 is sealed. This patent discharges the gas generated when the resin is solidified and then seals it. The gas is discharged and moisture gas is prevented from entering the box through the hole. But that patent deals with gases that are produced during the curing phase of the resin.

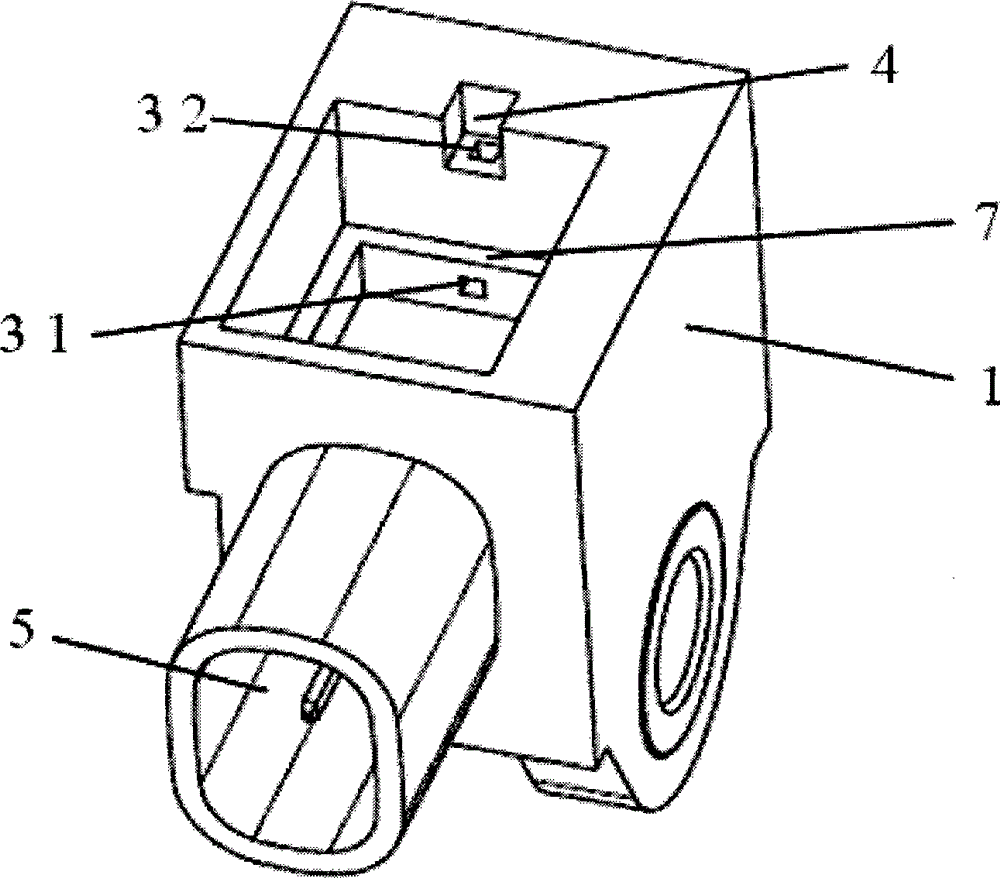

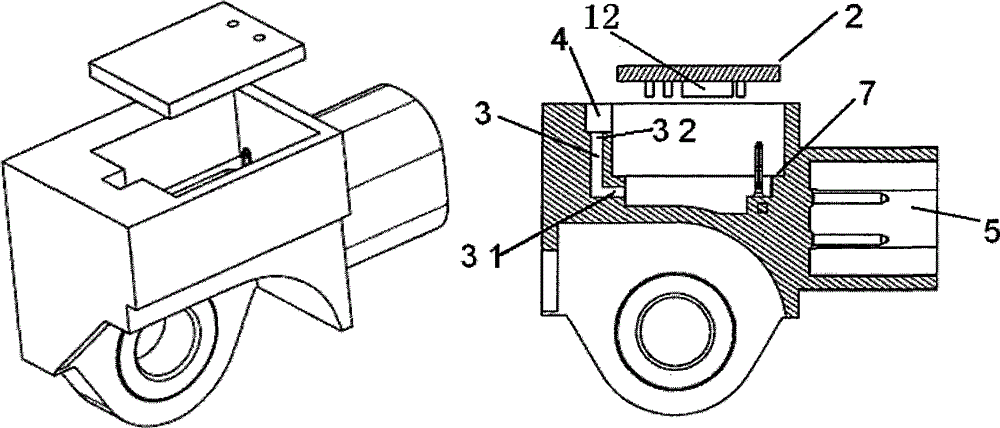

[0019] Figure 2 to Figure 4B It is a schematic diagram of the first embodiment of the present invention. As shown ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com