Arc-surface-lap-joint self-water-stop reverse-filtering trunk

A self-resistance, curved surface technology, applied in water conservancy projects, sea area projects, construction, etc., can solve problems such as difficult to ensure on-site, safe and effective, inconvenient maintenance and replacement, etc., to reduce upstream seepage pressure, meet safety and stability, The effect of ensuring the safety of dikes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

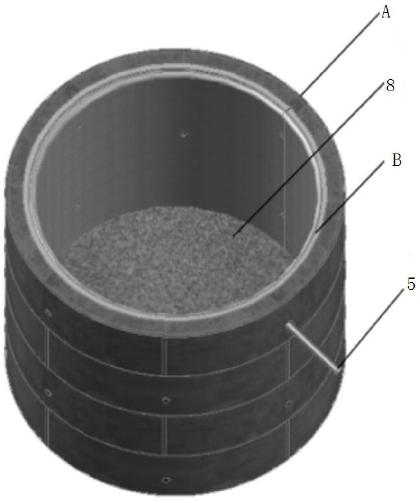

[0034] as attached Figures 1 to 5 As shown in the figure, a self-blocking water reverse filter surrounding well with arc-shaped overlapping, including a seepage well bottom 8, a basket is provided above the seepage well bottom 8, and several arc-shaped blocks 1 are arranged on the periphery of the basket. The well wall that 90 connects constitutes, and described well wall peripheral side is provided with drainage pipe 5.

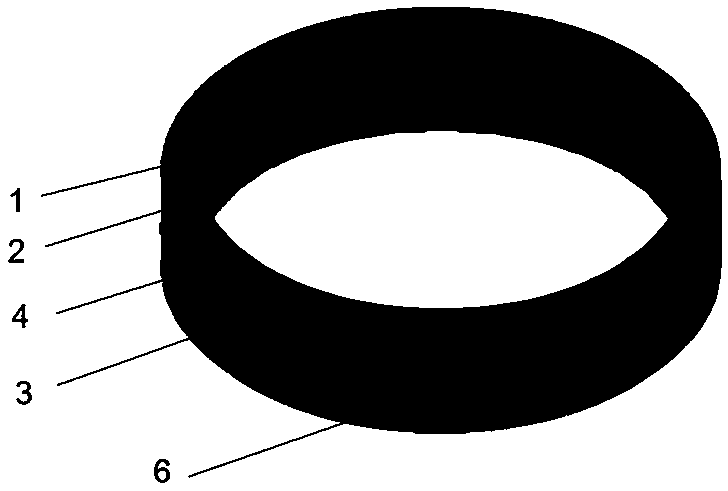

[0035] The basket includes an upper support ring 11 and a lower support ring 9, a barrel-shaped basket body 10 is provided between the upper support ring 11 and the lower support ring 9, and a circular basket bottom is provided on the lower support ring 9.

[0036] The circular basket bottom and barrel-shaped basket body 10 are all geotextiles, and the upper support ring 11 and the lower support ring 9 are both hollow or solid components made of elastic and bendable plastic.

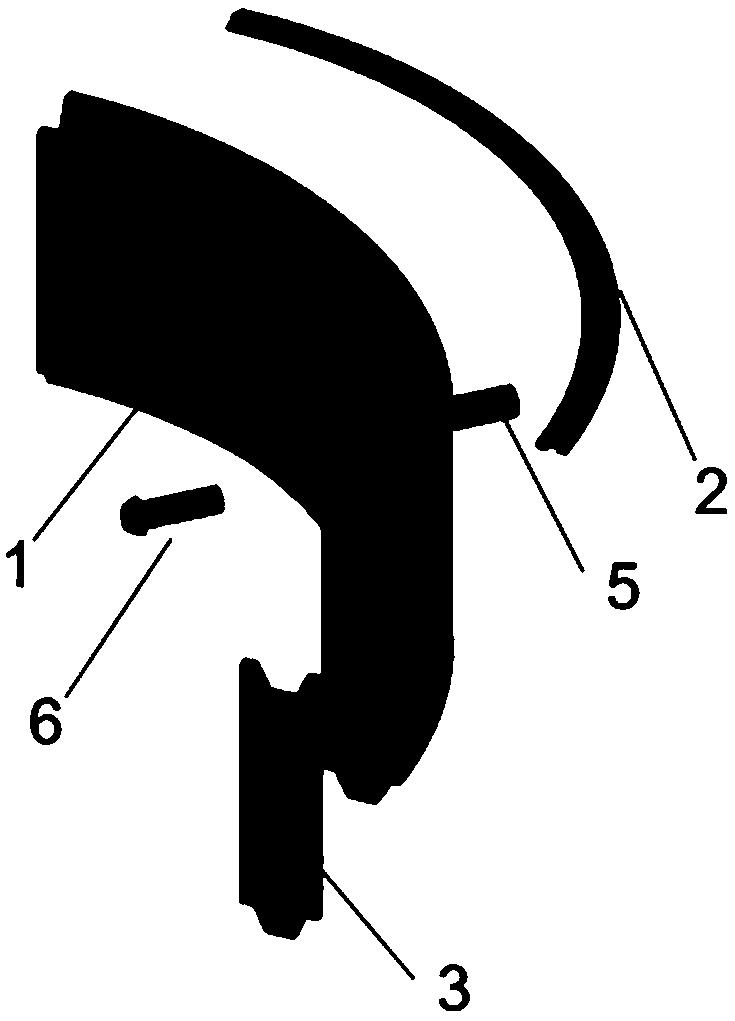

[0037] The well wall includes several arc-shaped blocks 1 that are self-locking ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com