Water gas hydrogen production equipment for natural gas processing

A technology for hydrogen production equipment and water gas, applied in the direction of sustainable manufacturing/processing, hydrogen, hydrogen separation, etc., can solve problems affecting hydrogen concentration, waste, etc., and achieve the effect of improving replacement efficiency and avoiding waste and danger

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

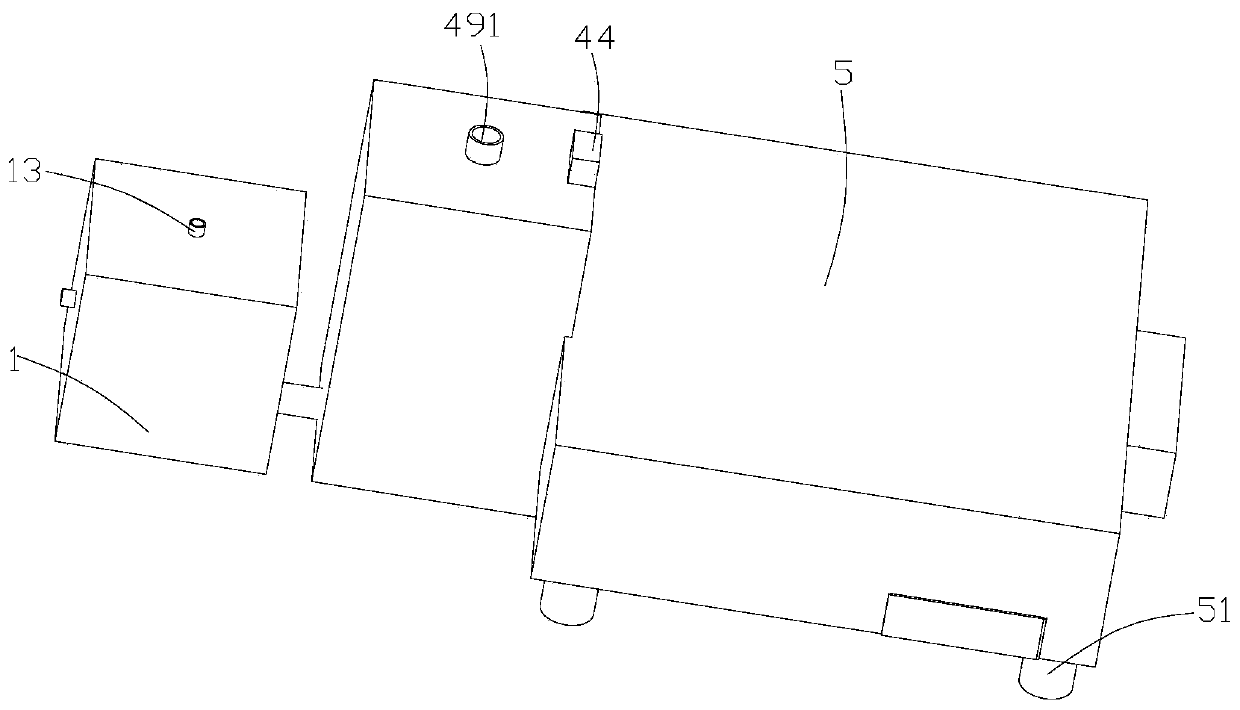

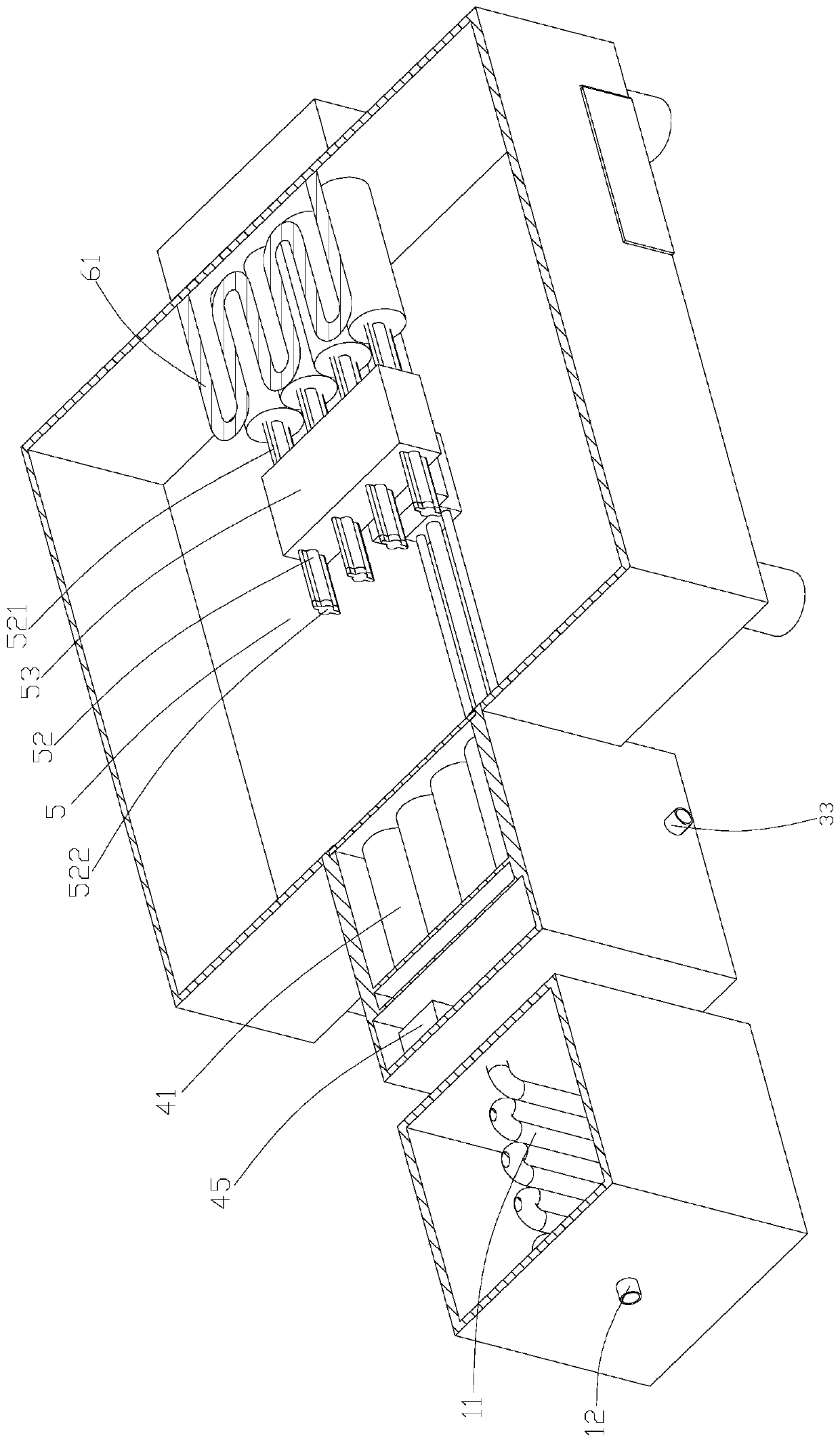

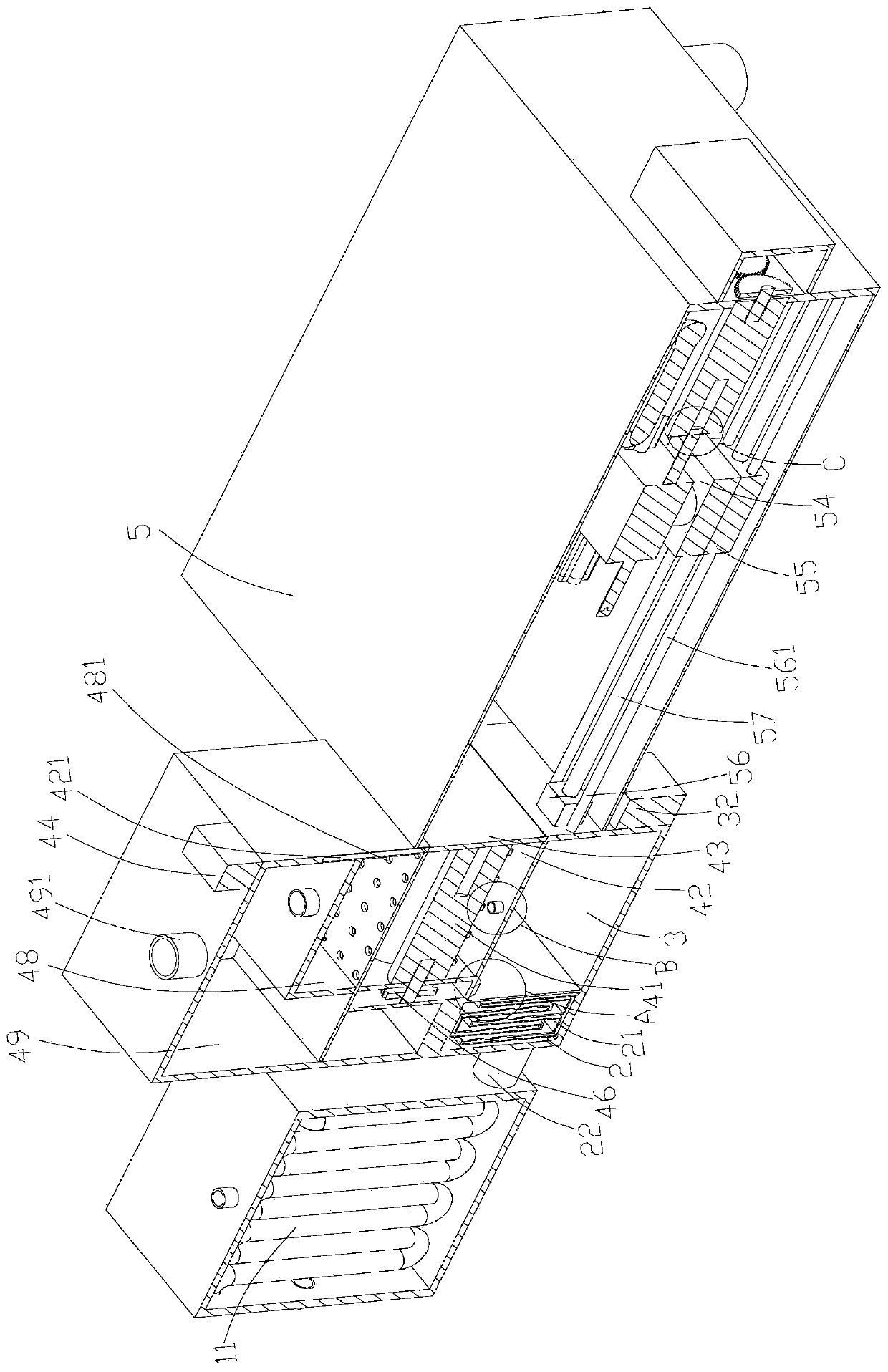

[0026] Such as Figure 1-11As shown, a water gas hydrogen production equipment for natural gas processing includes a reaction box 1 for reacting water gas and water vapor to produce hydrogen, and a spiral heating tube for heating the water gas and water vapor in the reaction box 1 11. The first gas pipeline 12 for transporting water vapor and the second gas pipeline 13 for transporting water gas also include a purification mechanism for purifying the produced hydrogen, and the purification mechanism includes The condensing chamber 2, the pressurization chamber 3 for separating carbon monoxide and a plurality of carbon dioxide adsorption blocks 41 for capturing carbon dioxide gas in hydrogen and the cleaning device for cleaning the carbon dioxide adsorption blocks, through the setting of the above structure, make the water gas When hydrogen is produced, the miscellaneous gas can be separated through the above-mentioned treatment chamber, so that pure hydrogen can be extracted, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com