Method and apparatus for droplet deposition

A droplet and equipment technology, applied in printing and other directions, can solve the problems of pattern limitation and printing failure, and achieve the effect of simplifying the integration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

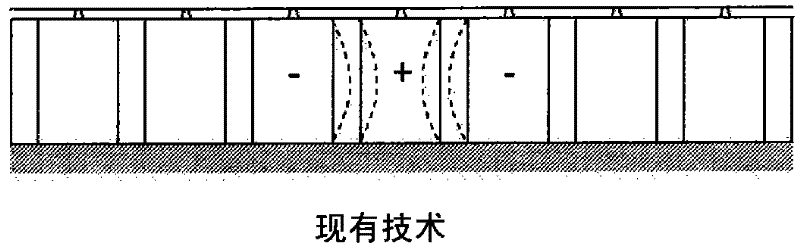

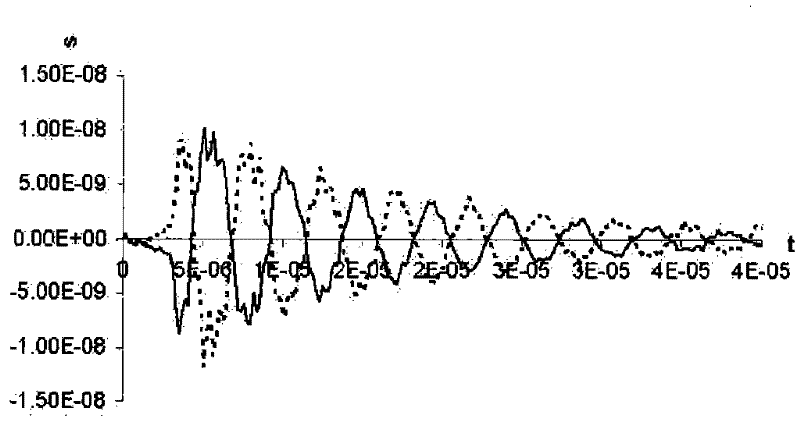

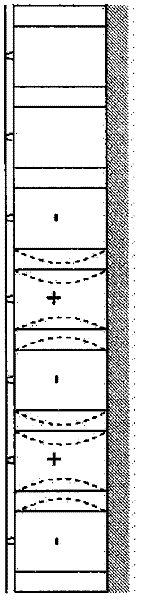

[0042] figure 1 The device shown can be used to perform the method of droplet deposition according to the present invention and comprises an array of fluid chambers extending in the direction of the array formed as channels or elongated cavities, each channel or elongated cavity having a A longitudinal axis extending in a direction such that each channel is elongated in this direction. The channel extension direction will preferably be perpendicular to the array direction. The channels are separated by corresponding arrays of elongated channel walls formed of piezoelectric material such as PZT, so that each channel is thus provided with two opposing side walls extending along the length of the cavity.

[0043] In order to provide the greatest density of deposited droplets, preferably each channel or cavity in the array is filled during use with an ejection fluid, such as ink, and is provided with holes or nozzles for ejecting the fluid.

[0044] exist figure 1 In a particul...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap