Abrasive, polishing method, method for manufacturing semiconductor integrated circuit device

A grinding method and an integrated circuit technology, which are applied in semiconductor/solid-state device manufacturing, grinding devices, polishing compositions containing abrasives, etc., and can solve the problem of overall complexity of the abrasive supply device, depression, cost and equipment installation space increase and other issues to achieve a high degree of planarization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~7

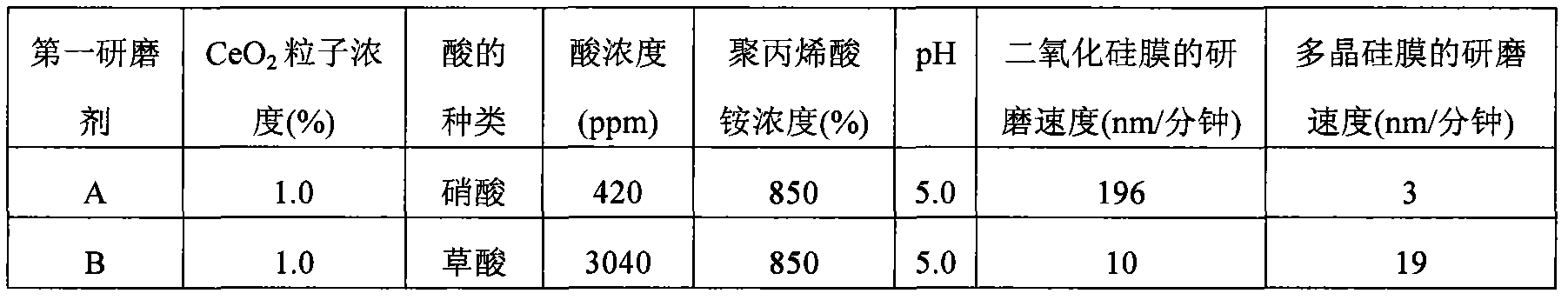

[0108] Mix the first grinding agent A and deionized water with a mass ratio of 1:3 (that is, carry out 4-fold dilution with deionized water), and add therein the amount of each ratio shown in Table 2 with respect to the total liquid mass as water-soluble Polyamine pentaethylene hexamine (PEHA). Abrasives (second abrasives) A1 to A7 having pH values shown in Table 2 were thus prepared, respectively.

[0109] Then, using the second abrasives A1 to A7 thus obtained, the above-mentioned objects to be polished (a silicon wafer substrate formed with a silicon dioxide film and a silicon wafer substrate formed with a polysilicon film) were respectively subjected to the grinding pressure shown in Table 3. Polishing was performed for 60 seconds, and the polishing characteristics (polishing speed Vso of the silicon dioxide film and polishing speed Vps of the polysilicon film) were measured respectively. Then, the polishing rate ratio (Vps / Vso) of the polysilicon film and the silicon d...

Embodiment 8

[0111] The mass ratio of 1:9 in Example 8 and the mass ratio of 1:99 in Example 9 were mixed with the first grinding agent A and deionized water, and 0.1% of PEHA was added thereto relative to the total mass of the liquid. Thus, abrasives (second abrasives) A8 and A9 having pH values shown in Table 2 were prepared, respectively.

[0112] Then, using the second abrasives A8 and A9 thus obtained, the above-mentioned objects to be polished (a silicon wafer substrate formed with a silicon dioxide film and a silicon wafer substrate formed with a polysilicon film) were respectively subjected to the grinding pressure shown in Table 3. Polishing was performed for 60 seconds, and the polishing speed Vso of the silicon dioxide film and the polishing speed Vps of the polysilicon film were respectively measured. Then, the polishing rate ratio (Vps / Vso) of the polysilicon film and the silicon dioxide film was calculated from these measured values, respectively. These results are shown i...

Embodiment 10~13

[0114] The first grinding agent A and deionized water were mixed at a mass ratio of 1:3, and polyoxypropylene having a weight average molecular weight (Mw) of 230 as a water-soluble polyamine was added in the ratios shown in Table 2 to the total liquid mass. Diamine (POPD) (manufactured by BASF, trade name, POLYETHERAMINE). Abrasives (second abrasives) A10 to A13 having pH values shown in Table 2 were thus prepared, respectively.

[0115] Then, using the second abrasives A10 to A13 thus obtained, the above-mentioned objects to be polished (a silicon wafer substrate formed with a silicon dioxide film and a silicon wafer substrate formed with a polysilicon film) were subjected to the grinding pressure shown in Table 3, respectively. Polishing was performed for 60 seconds, and the polishing speed Vso of the silicon dioxide film and the polishing speed Vps of the polysilicon film were respectively measured. Then, the polishing rate ratio (Vps / Vso) of the polysilicon film and th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com